A4 Mk2

|

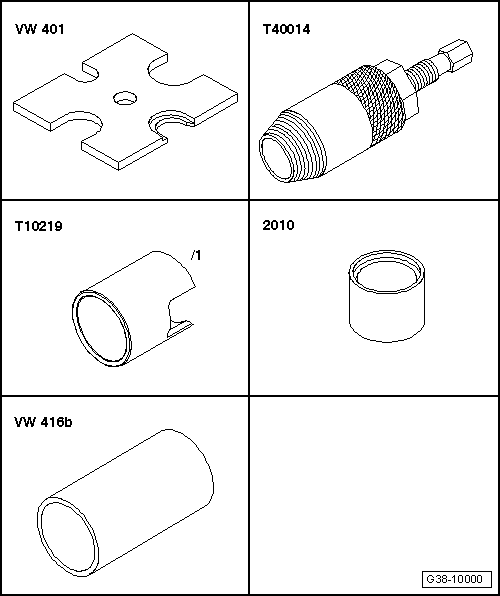

| Special tools and workshop equipment required |

| t | Thrust plate -VW 401- |

| t | Oil seal extractor -T40014- |

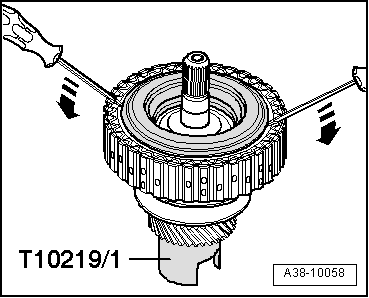

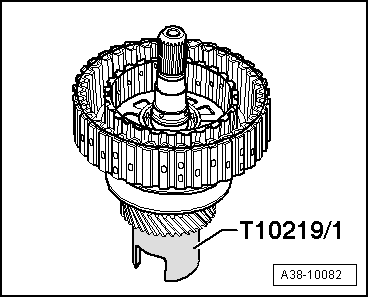

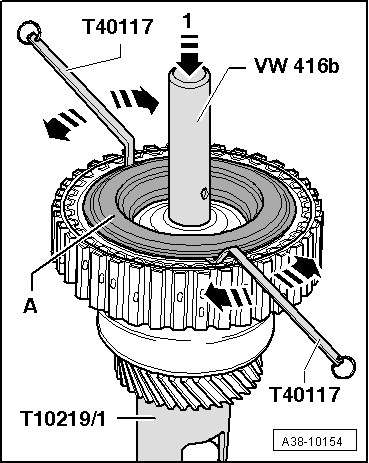

| t | Assembly tool -T10219/1- |

| t | Tube -2010- |

| t | Tube -VW 416 B- |

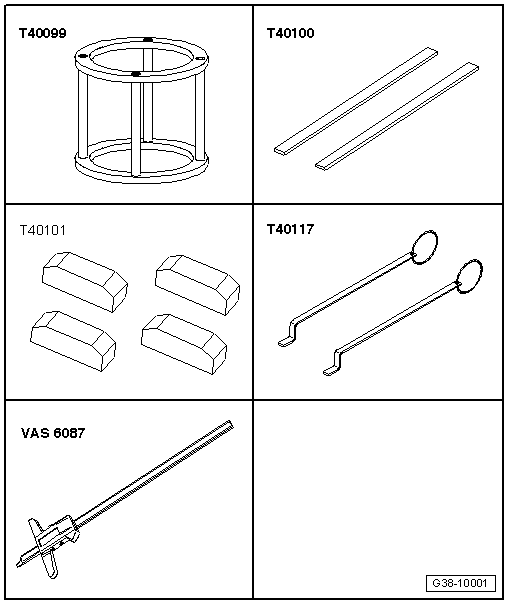

| t | Thrust piece -T40099- |

| t | 2x ruler -T40100- |

| t | Gauge block (1 set contains 4) -T40101- |

| t | Feeler gauge (2x) -T40117- |

| t | Digital depth gauge -VAS 6087- |

| t | Protective gloves |

| t | Ice spray |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution