A4 Mk2

| Servicing drive shaft (with 100 mm dia. inner constant velocity joint) |

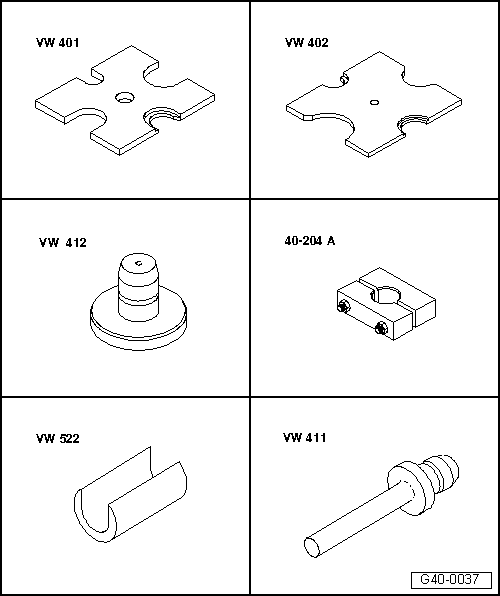

| Special tools and workshop equipment required |

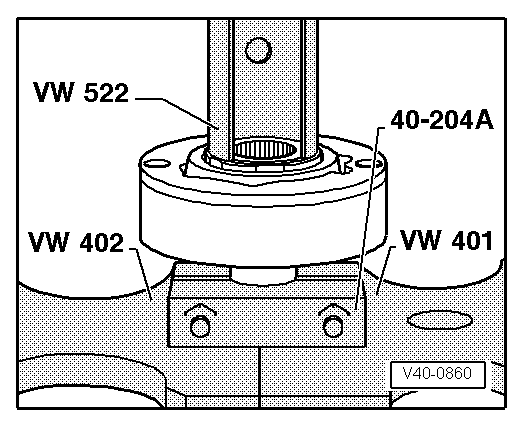

| t | Thrust plate -VW 401- |

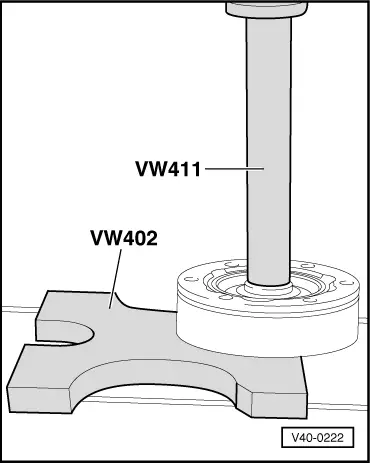

| t | Thrust plate -VW 402- |

| t | Press tool -VW 412- |

| t | Tensioner -40-204 A- |

| t | Support sleeve -VW 522- |

| t | Press tool -VW 411- |

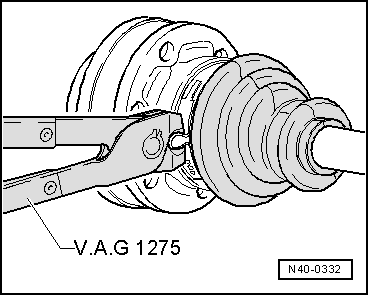

| t | Hose clip pliers -V.A.G 1275- |

|

|

| Grease quantity | of which in: | ||

| Outer joint | Total quantity | Joint | Boot |

| [mm] | [g] | [g] | [g] |

| 88 | 90 | 40 | 50 |

| Inner joint | Put in grease through ball bearing races | ||

| 100 | 80 | ||

|

| 1 - | Cover |

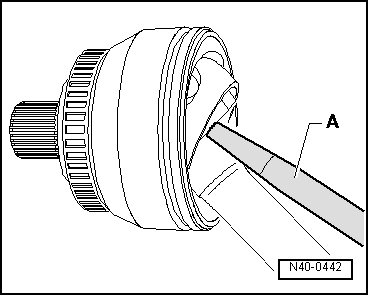

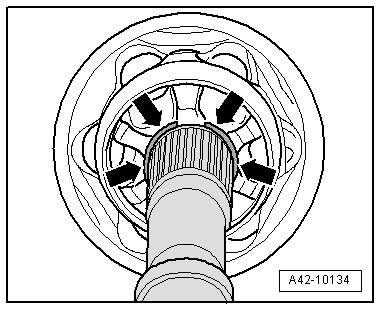

| q | Drive off carefully with drift → Fig. |

| q | Always renew |

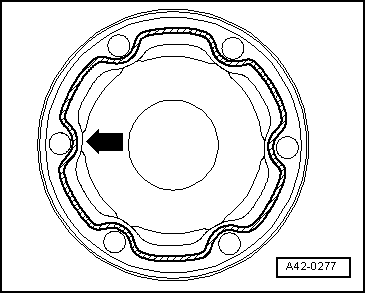

| q | Before fitting on constant velocity joint, coat sealing surface with D 454 300 A2 → Fig. |

| q | Align cover with bolt holes |

| 2 - | Circlip |

| q | Use normal commercial circlip pliers when removing and installing |

| q | Always renew |

| 3 - | Inner constant velocity joint |

| q | Outside diameter: 100 mm |

| q | Renew only as complete unit |

| q | Pressing off → Fig. |

| q | Pressing on → Anchor |

| q | Greasing → Anchor |

| q | Adhesive surfaces must be free of oil and grease |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

| 4 - | Lock plate |

| 5 - | Multi-point socket head bolt |

| q | For correct version refer to → Parts catalogue |

| q | Tightening torques: |

| M 8 bolt: 40 Nm |

| M10 bolt: 65 Nm |

| 6 - | Boot with cap for inner constant velocity joint |

| q | With vent hole |

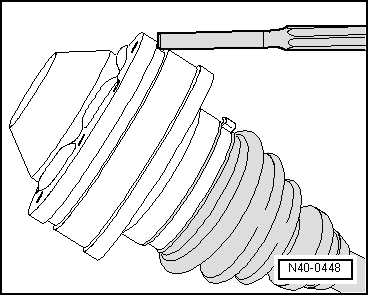

| q | Drive cap off carefully with drift |

| q | Always renew |

| q | Check inner constant velocity joint if boot is damaged → Chapter |

| q | Before fitting on constant velocity joint, coat sealing surface with D 454 300 A2 → Fig. |

| q | Align cover with bolt holes |

| q | Sealing surfaces (boot/drive shaft) must be free from grease when assembling |

| 7 - | Drive shaft |

| 8 - | Boot for outer constant velocity joint |

| q | Without vent hole |

| q | Check for splits and chafing, renew if necessary |

| q | Check outer constant velocity joint if boot is damaged → Chapter |

| q | Sealing surfaces (boot/drive shaft and boot/joint) must be free from grease when assembling |

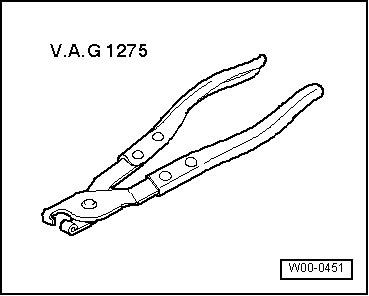

| 9 - | Hose clip |

| q | Always renew |

| q | Tightening → Fig. |

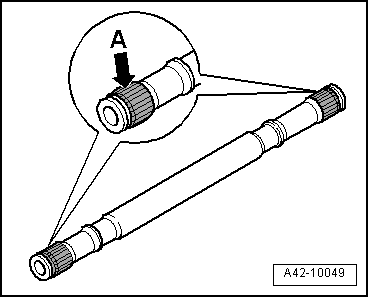

| 10 - | Circlip |

| q | Always renew |

| q | For correct version refer to → Parts catalogue |

| q | Insert in groove on shaft |

| 11 - | Outer constant velocity joint |

| q | Outside diameter: 88 mm |

| q | Renew only as complete unit |

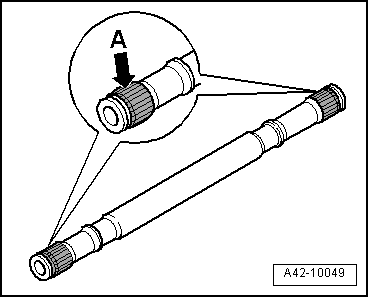

| q | Driving off → Fig. |

| q | Installing: drive onto shaft with plastic hammer until compressed circlip seats |

| q | Circlip must fit in chamfer on joint when installing; guide with pliers if necessary |

| q | Greasing → Anchor |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

| 12 - | Flange bolt |

| q | Always renew |

| q | Tightening torque → Item |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|