A4 Mk3

| Exploded view - clutch release mechanism |

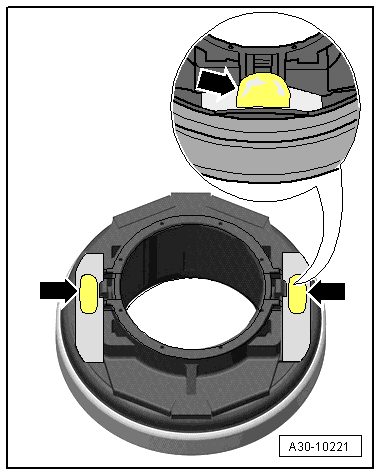

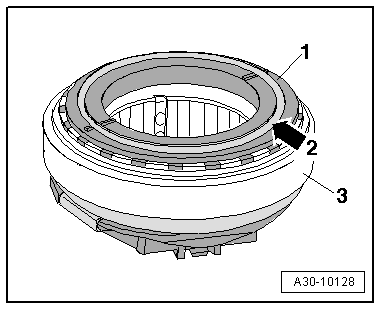

| 1 - | Release bearing with tumbler ring |

| q | Checking → Fig. |

| q | Do not wash out; wipe clean only |

| q | Renew bearing if noisy |

| q | Retainer lugs on release bearing must engage in release lever |

| q | Removing and installing → Chapter |

Note

Note| t | Grease bearing surface for clutch release lever thoroughly with lubricating paste -G 000 150- → Fig. |

| t | If applicable, remove the grease at the mounting point for the guide sleeve - grease-free mounting on guide sleeve |

| 2 - | Clutch release lever |

| q | Remove existing grease from release lever |

| q | Re-grease the bearing point for the release bearing -arrows A- with lubricating paste -G 000 150- |

| q | Removing and installing → Chapter |

| 3 - | Retaining spring |

| q | Engage on clutch release lever |

| 4 - | Intermediate piece |

| q | Renew if damaged |

| 5 - | Ball-head pin |

| q | 25 Nm |

| q | Grease the bearing surface for the clutch release lever -arrow B- with grease for clutch plate splines -G 000 100- |

| 6 - | Gearbox |

| 7 - | Clutch slave cylinder |

| q | Removing and installing → 6-speed manual gearbox 0B3, front-wheel drive; Rep. Gr.30 |

| q | Do not operate clutch pedal after slave cylinder has been removed |

| q | Keep to the bleeding sequence → 6-speed manual gearbox 0B3, front-wheel drive; Rep. Gr.30 |

| q | When installing, push in until the securing bolt can be fitted. |

| 8 - | Guide sleeve |

| l | If applicable, remove the grease on the guide sleeve - grease-free mounting of release bearing with tumbler ring on guide sleeve |

| 9 - | Bolt |

| q | 8 Nm |

| q | 2x |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

|

|

Caution

Caution