| –

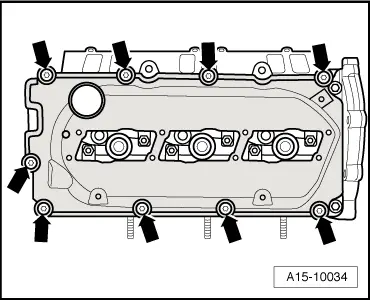

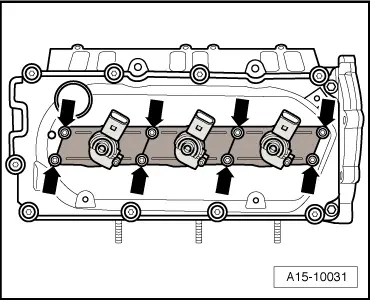

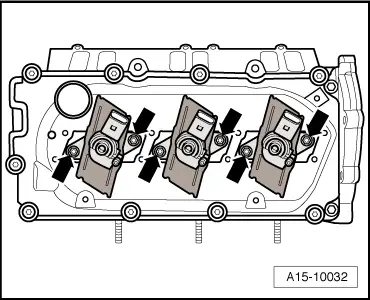

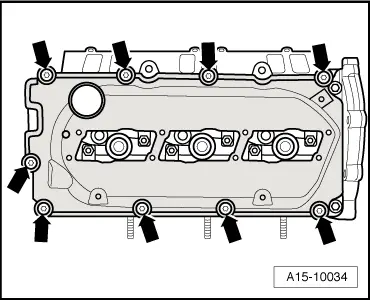

| Loosen bolts -arrows- on cylinder head cover in diagonal sequence. |

| –

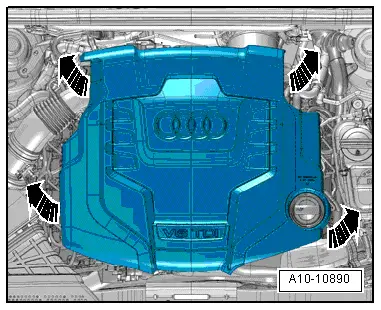

| Remove bolts and take off cylinder head cover. |

| Installation is carried out in the reverse order; note the following: |

Note | t

| Renew gasket for cylinder head cover if damaged. |

| t

| Renew bolts for cylinder head cover if seals on bolts are damaged. |

| t

| Hose connections and air pipes and hoses must be free of oil and grease before assembly. |

| t

| To ensure that the air hoses can be properly secured at their connections, spray rust remover onto the worm thread of used hose clips before installing. |

| –

| Clean sealing surfaces; they must be free of oil and grease. |

| –

| Tighten bolts for cylinder head cover in diagonal sequence and in stages. |

| –

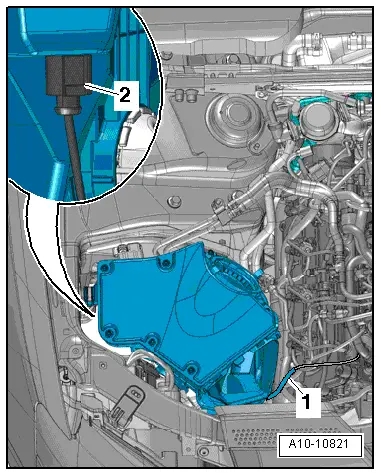

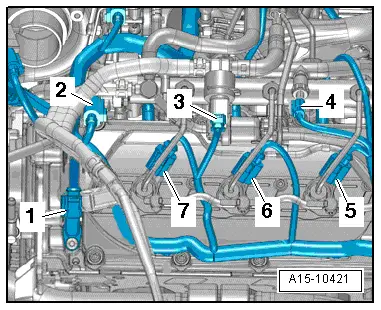

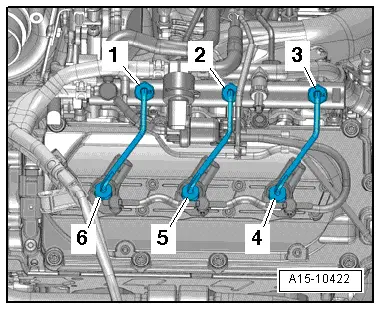

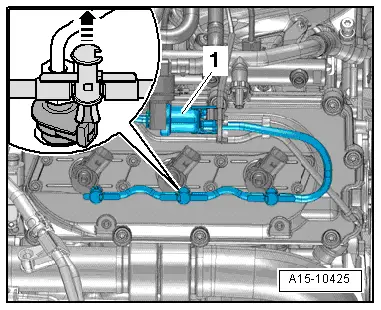

| Install injectors, high-pressure pipes, air cleaner housing and exhaust gas pressure sensor 1 -G450- → Rep. gr.23. |

|

|

|

Note

Note

Note

Note

Caution

Caution