A5

| Removing gearbox – vehicles with 4-cylinder diesel engine |

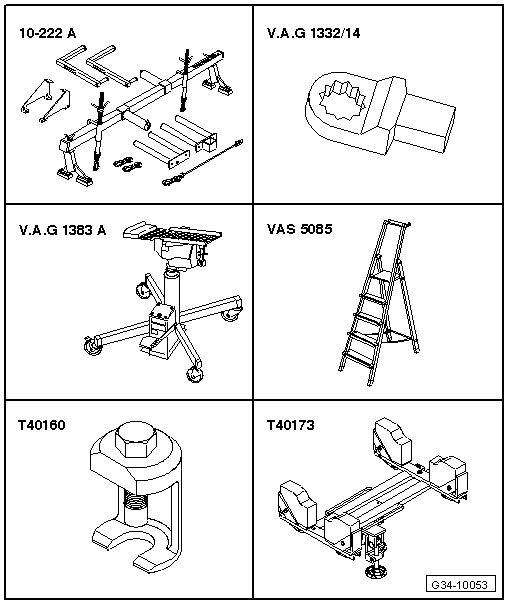

| Special tools and workshop equipment required |

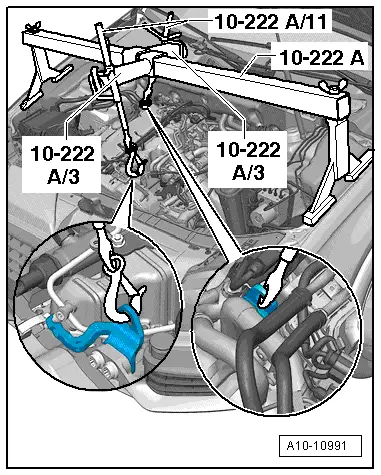

| t | Support bracket -10 - 222 A- |

| t | Ring spanner insert, 16 mm -V.A.G 1332/14- |

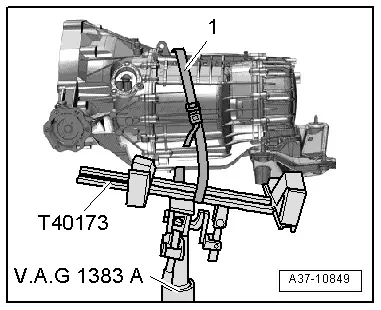

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

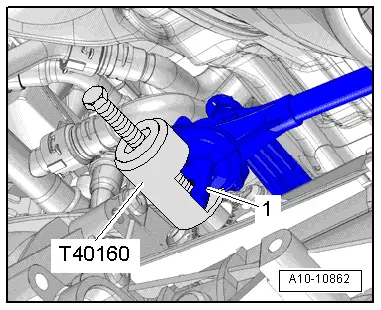

| t | Puller -T40160- |

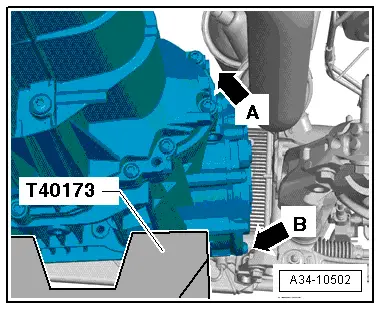

| t | Gearbox support -T40173- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution WARNING

WARNING