A5

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

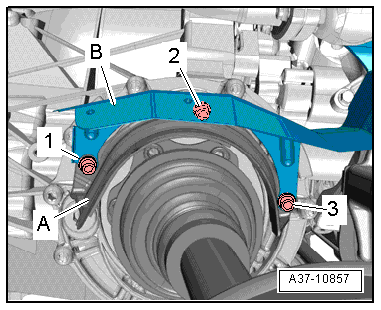

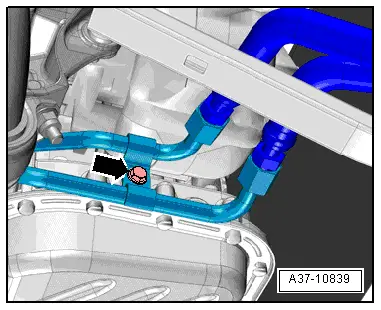

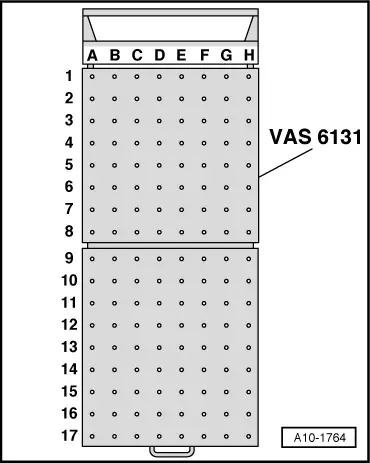

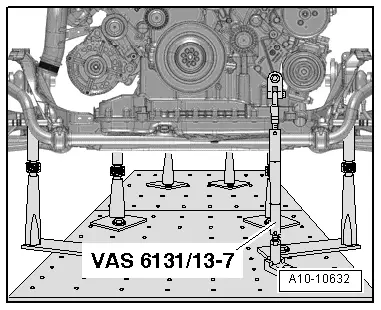

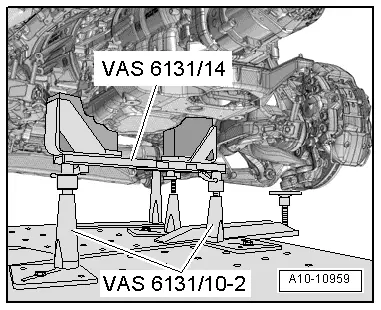

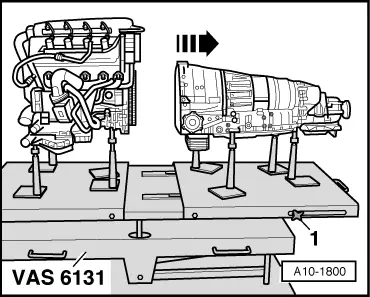

| Platform coordinates | Parts of support set for Audi -VAS 6131/10-, supplementary set -VAS 6131/13- and gearbox support -VAS 6131/14- | |||

| D2 | /13-7 | |||

| B10 | /10-1 | /10-2 | /10-5 | /14 |

| G10 | /10-1 | /10-2 | /10-5 | |

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution