| t

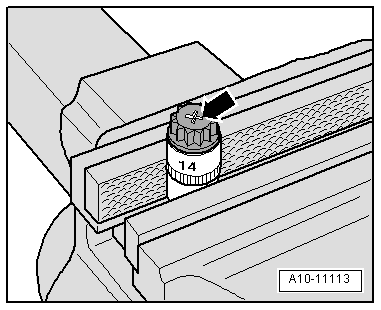

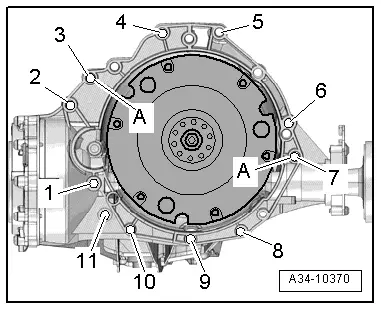

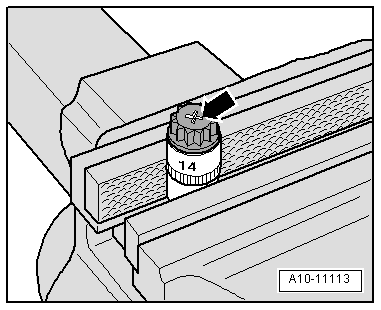

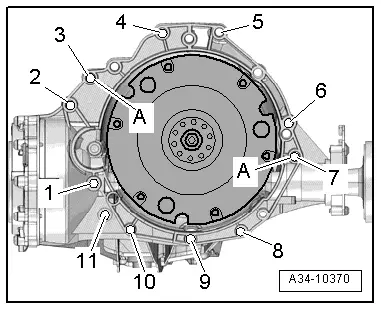

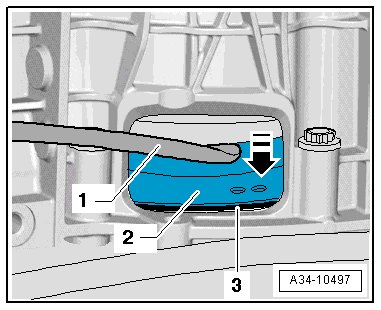

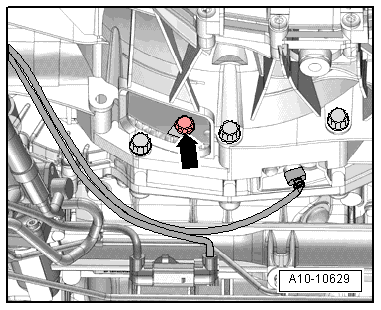

| The aluminium bolts -2 … 11- must not be used more often than twice. After the first use, the bolts must therefore be identified with an „X“ made by two chisel marks -arrow-. |

| t

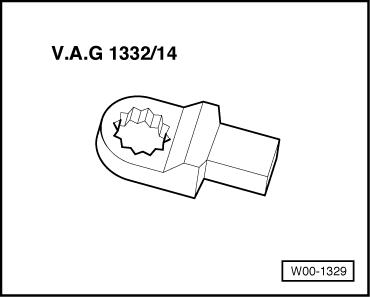

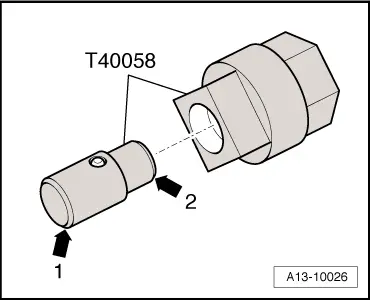

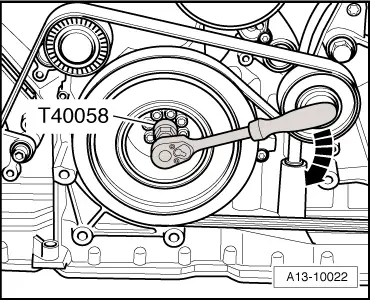

| To avoid damaging the bolts when making this mark, do not clamp them directly in a vice. Clamp a 14 mm socket with 1/2" drive in a vice and insert the bolt as shown. |

| t

| Bolts already marked with an „X“ must not be used again. |

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

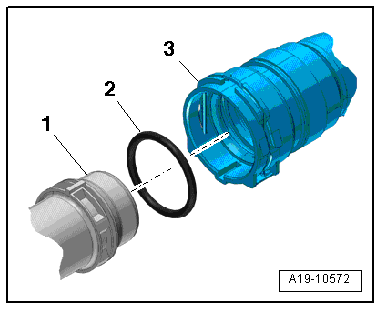

| Renew self-locking nuts and bolts as well as seals, gaskets and O-rings. |

| t

| On vehicles with dual clutch gearbox 0B5, a needle bearing is fitted in the drive plate. Before installing, check that the needle bearing is fitted. Removing and installing needle bearing in drive plate (pressing in and out) → Chapter. |

| t

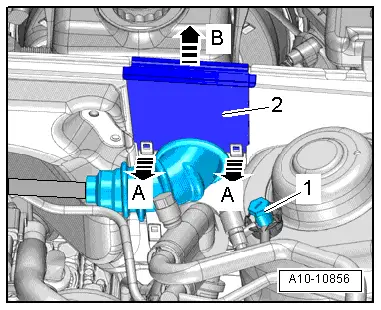

| Hose connections and air pipes and hoses must be free of oil and grease before assembly. |

| t

| To ensure that the air hoses can be properly secured at their connections, spray rust remover onto the worm thread of used hose clips before installing. |

| t

| Fit all cable ties in the original positions when installing. |

| –

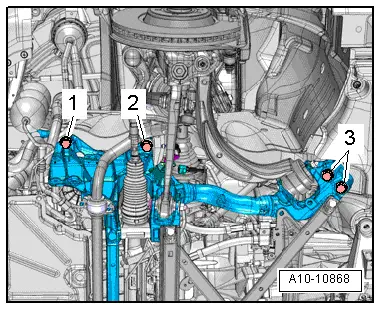

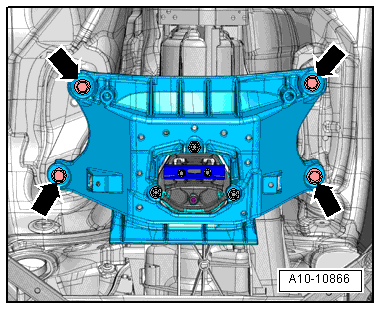

| Install engine supports and engine mountings → Chapter. |

| –

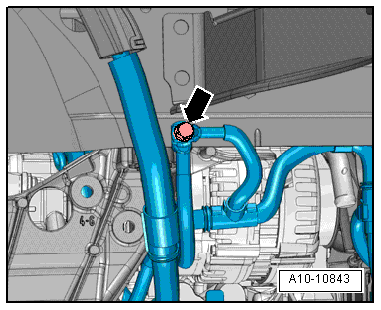

| Install coolant pipe (bottom right) → Chapter. |

| –

| Hold ATF lines in installation position when joining engine and subframe. |

| –

| Before installing gearbox, remove residue from threaded holes for engine/gearbox bolts in cylinder block using a thread tap. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution