Inspection of Valves and Guides during 300Tdi Engine Overhaul - Cylinder Head

ENGINE

OVERHAUL

21

Valve springs - inspection

1. Check free length of each spring = 46.28 mm

2. Check that end coils of each spring are square

to body of spring.

Valves and guides - inspection

1. Remove carbon from valves.

2. Examine head of each valve for cracks and

burning and valve seat for pitting or burning,

replace valves as necessary.

3. Check valve seating faces for pitting, if light

pitting cannot be removed during valve

grinding operations, valves may be refaced.

CAUTION: If refacing results in valve head

stand down being exceeded, valves must

be replaced.

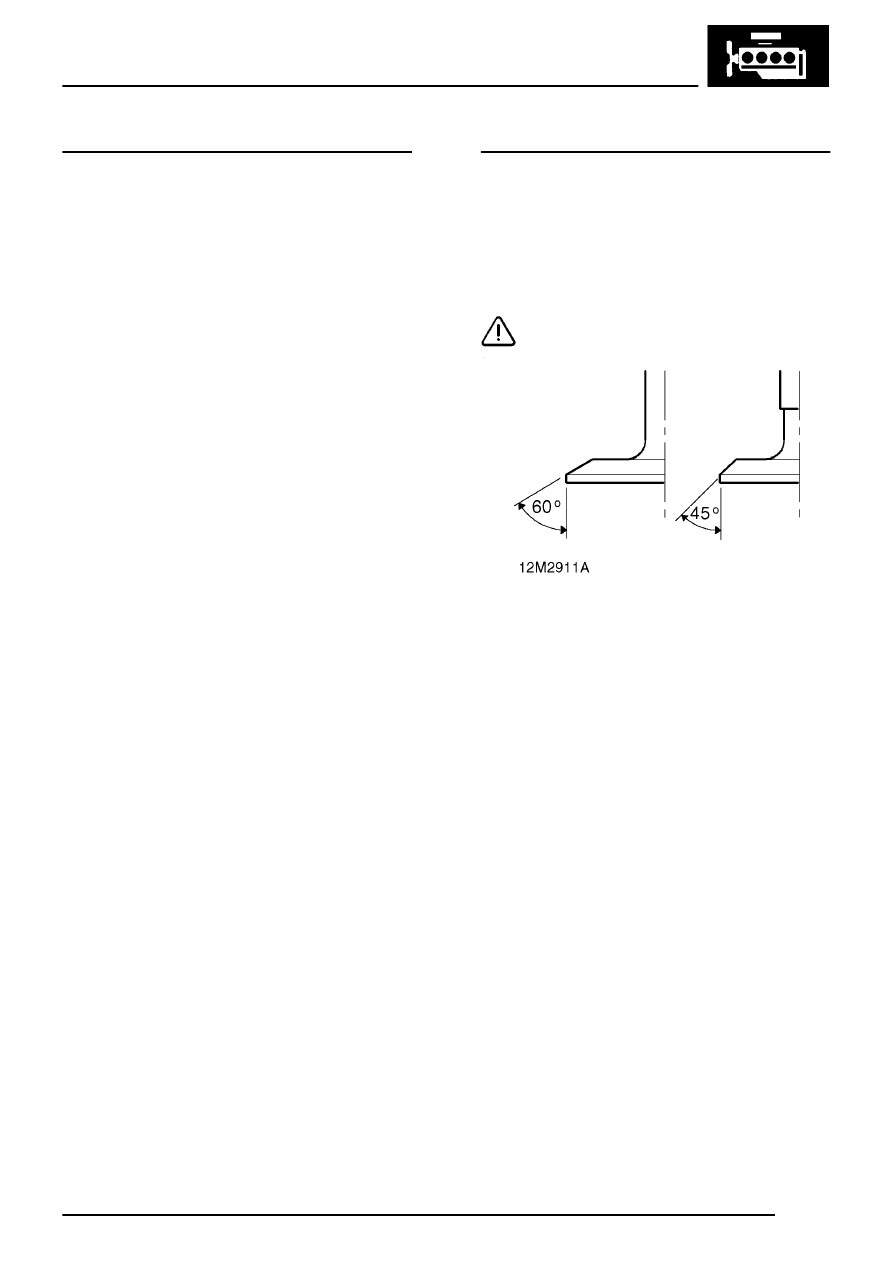

4. Check valve seating face angles.

Inlet = 60

°

00’ to 60

°

30’ - included angle =120

°

Exhaust = 45

°

00’ to 45

°

30’ - included angle =

90

°

5. Reface or replace valves as necessary.

6. Check each valve stem for wear, measure at

each end and centre of valve stem.

Inlet = 7.96 mm

Exhaust = 7.94 mm

7. Replace any valve with stems that are worn.