300Tdi Engine Valve Clearances - Adjustments

ENGINE

OVERHAUL

17

VALVE CLEARANCES - ADJUST

CAUTION: To prevent possibility of

damage to cam follower seatings, it is

essential that ball ends of tappet adjusting

screws are seated in recess in push rods and

that ball end of each push rod is correctly

located in cam follower slide.

1. Rotate crankshaft by means of crankshaft

pulley bolt in a clockwise direction until number

8 valve ( counting from front of engine ) is fully

open.

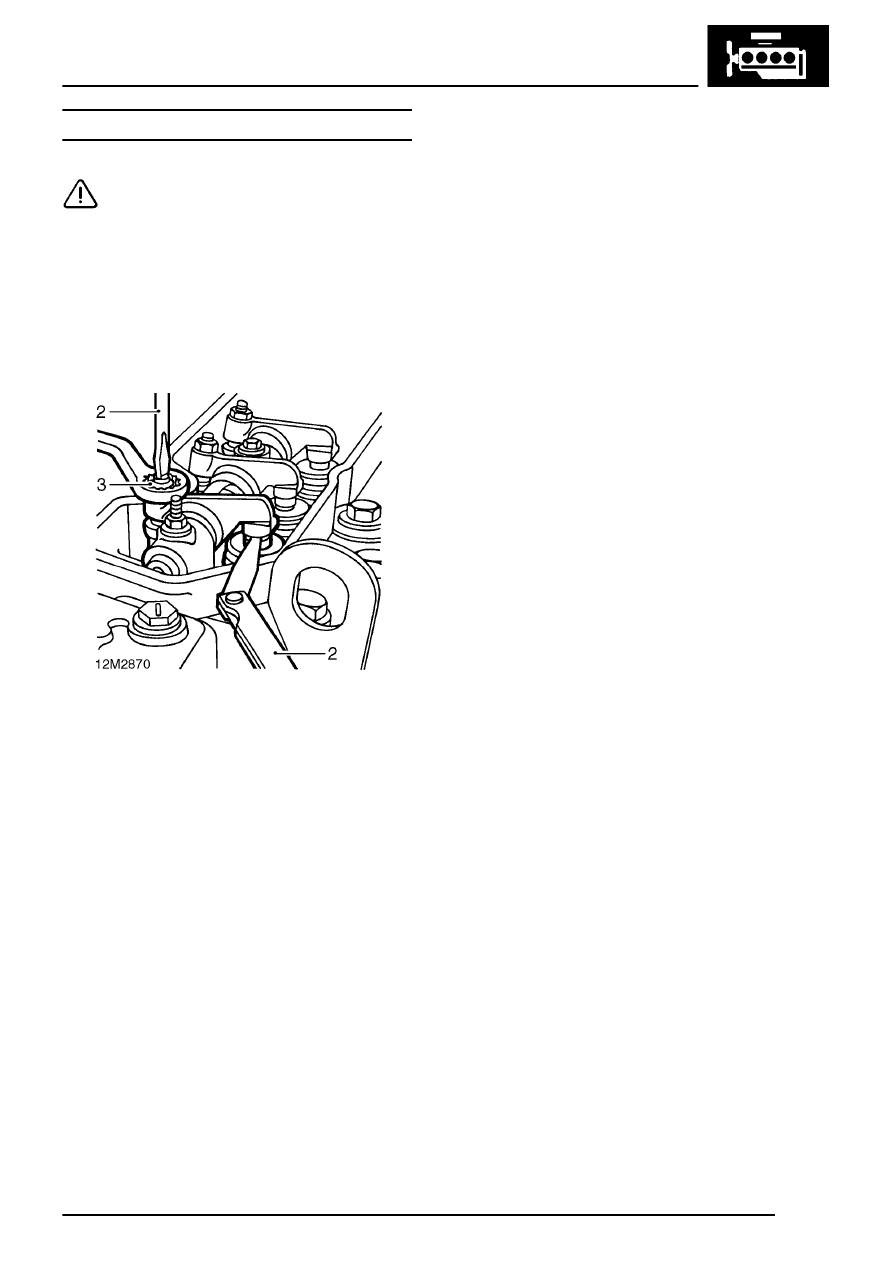

2. Using feeler gauges and a screwdriver, adjust

clearance of number 1 valve.

Valve clearance - all valves = 0.20 mm

3. Tighten tappet adjusting screw locknut when

clearance is correct.

4. Adjust the remaining valve clearances in the

following sequence:

Adjust number 3 clearance with number 6

valve fully open

Adjust number 5 clearance with number 4

valve fully open

Adjust number 2 clearance with number 7

valve fully open

Adjust number 8 clearance with number 1

valve fully open

Adjust number 6 clearance with number 3

valve fully open

Adjust number 4 clearance with number 5

valve fully open

Adjust number 7 clearance with number 2

valve fully open

5. Upon completion, re-check all clearances and

adjust as necessary.