300Tdi Defender Master Cylinder | Brakes | Page 466

BRAKES

3

OVERHAUL

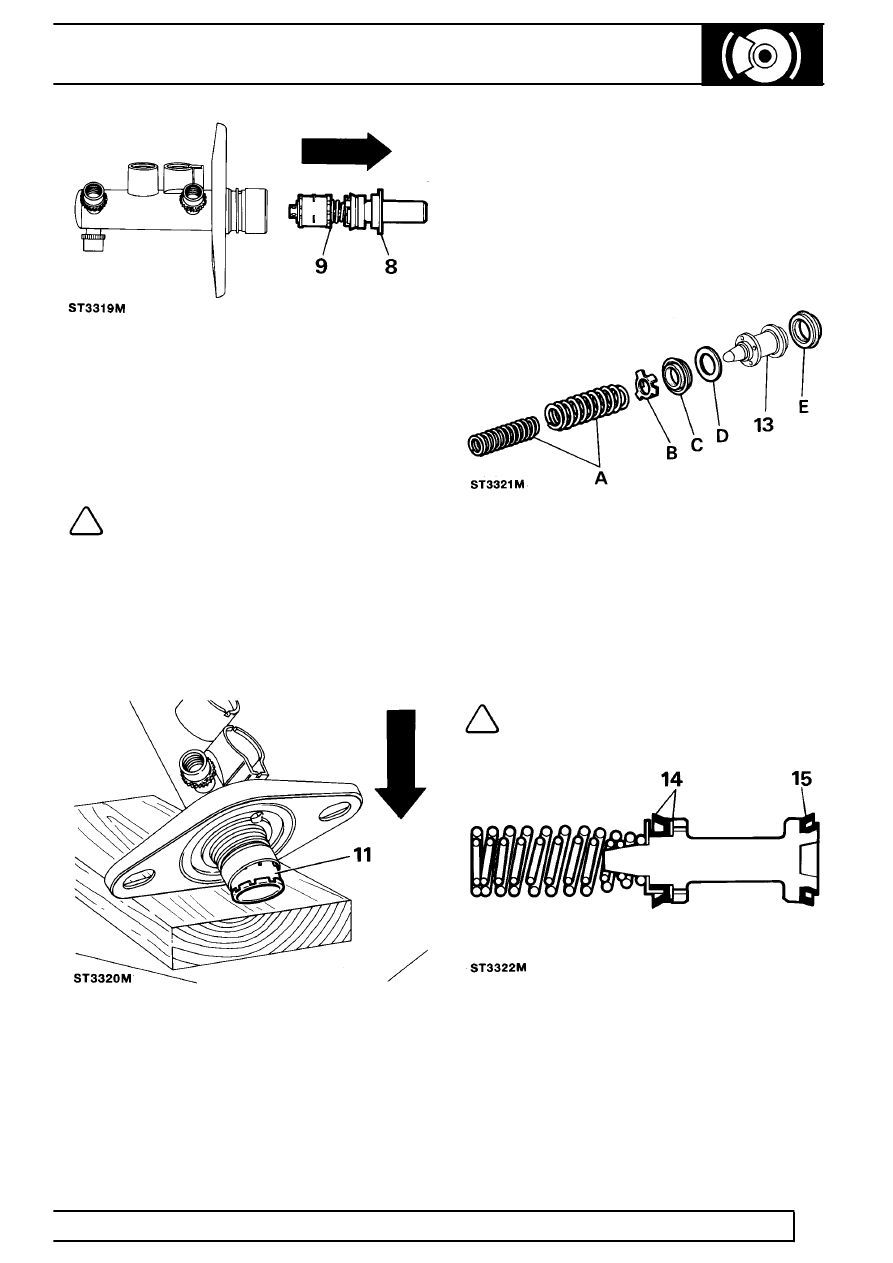

8. Remove guide ring from mouth of master

cylinder which supports primary plunger

assembly and place to one side, this component

is not part of master cylinder service kit and is to

be refitted on assembly of unit.

9. Pull primary plunger assembly out of master

cylinder.

NOTE: The primary plunger assembly

cannot be broken down any further and is

serviced as a complete unit. Discard

assembly.

10. The secondary plunger assembly will remain at

bottom of master cylinder bore, plunger can be

easily expelled by tapping assembly on a piece

of timber until plunger appears at cylinder mouth,

carefully pull plunger from master cylinder.

11. If swirl tube was not expelled at same time as

secondary plunger, repeat above operation to

expel it from bottom of master cylinder bore and

discard.

12. Clean all parts with Girling cleaning fluid or

unused brake fluid and place cleaned parts on to

a clean sheet of paper. Inspect cylinder bore and

plungers for signs of corrosion, ridges and score

marks. Provided working surfaces are in perfect

condition, new seals from a Girling Service

repair kit may be used.

Renewing secondary plunger seals

A. Springs

B. Seal retainer

C. Recuperating seal (primary cup)

D. Washer

E. ’L’ seal

13. Remove components above from secondary

plunger and discard:

NOTE: A small screwdriver with end

rounded and polished is required to

remove ’L’ seal. DO NOT damage

secondary plunger.

14. Coat new seals in unused brake fluid and firstly

fit ’L’ seal to plunger.

15. Fit washer followed by recuperating seal. Fit seal

retainer and springs, ensure springs are

correctly seated.