300Tdi Defender

12

ENGINE

10

REPAIR

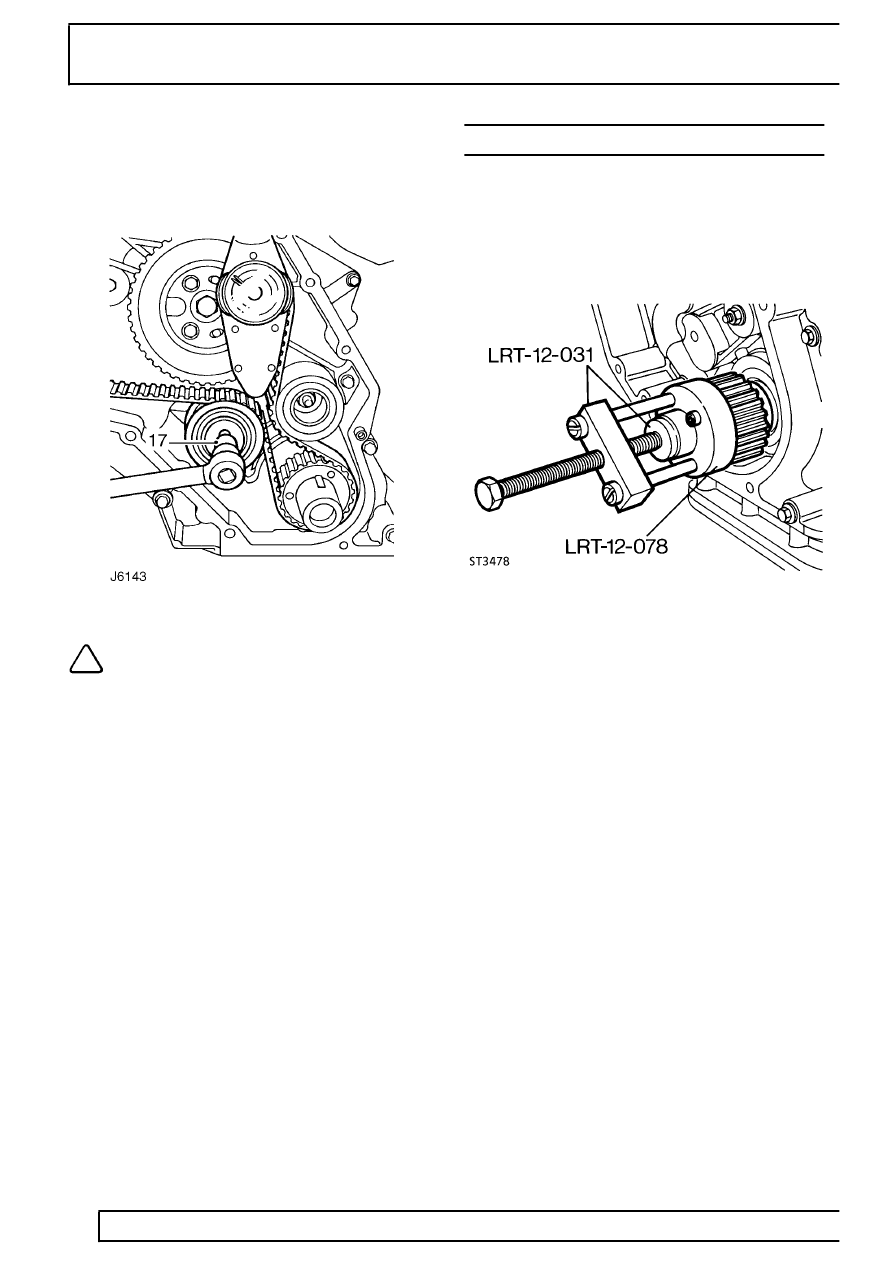

17. Slacken belt tensioner securing bolt to finger

tight.

18. Insert 13 mm square drive extension bar in

tensioner plate.

NOTE: Belt tensioning should be carried

out using a dial type torque meter having a

range not exceeding

60 Nm (44 lbf/ft). The

torque meter should be used in the almost vertical

position.

19. Apply a tension of

15 Nm (11 lbf/ft) for a new

belt or

12 Nm (9 lbf/ft) for an original belt. When

tension is correct, tighten clamp bolt.

20. Tighten injection pump gear bolts.

21. Remove pin from injection pump gear.

22. Disengage timing pin from timing slot in flywheel

or ring gear.

23. Rotate crankshaft one and three quarter turns in

a clockwise direction; then continue rotation until

timing pin in timing tool can be engaged with slot

in flywheel.

24. Disengage timing pin.

25. Insert pin from special tool LRT-12-045 in

injection pump gear and through into pump

flange.

26. Slacken injection pump gear retaining bolts.

27. Slacken tensioner and retension belt.

28. Tighten injection pump gear retaining bolts.

29. Remove pin from injection pump gear.

30. Remove timing tool and refit plug.

31. Fit front cover plate using new gaskets.

See Front cover plate and seal

CRANKSHAFT GEAR

Service repair no - 12.65.25

Remove

1. Remove camshaft drive belt.

See Camshaft

drive belt

2. If the crankshaft gear cannot be removed by

hand, use special tool LRT-12-078 with main

body and thrust button from special tool

LRT-12-031, as illustrated . Withdraw gear

complete with ’O’ ring seal.

Refit

3. Lubricate new ’O’ ring seal with petroleum jelly

and slide onto crankshaft, taking care not to

damage seal on woodruff keys.

4. Fit crankshaft gear and tap fully home ensuring

’O’ ring seal is properly seated.

5. Fit camshaft drive belt.

See Camshaft drive

belt