300Tdi Defender Rear Axle and Final Drive Assembly 329

REAR AXLE AND FINAL DRIVE

9

OVERHAUL

Differential backlash checks

96. Pick up differential unit as left after instruction

52.

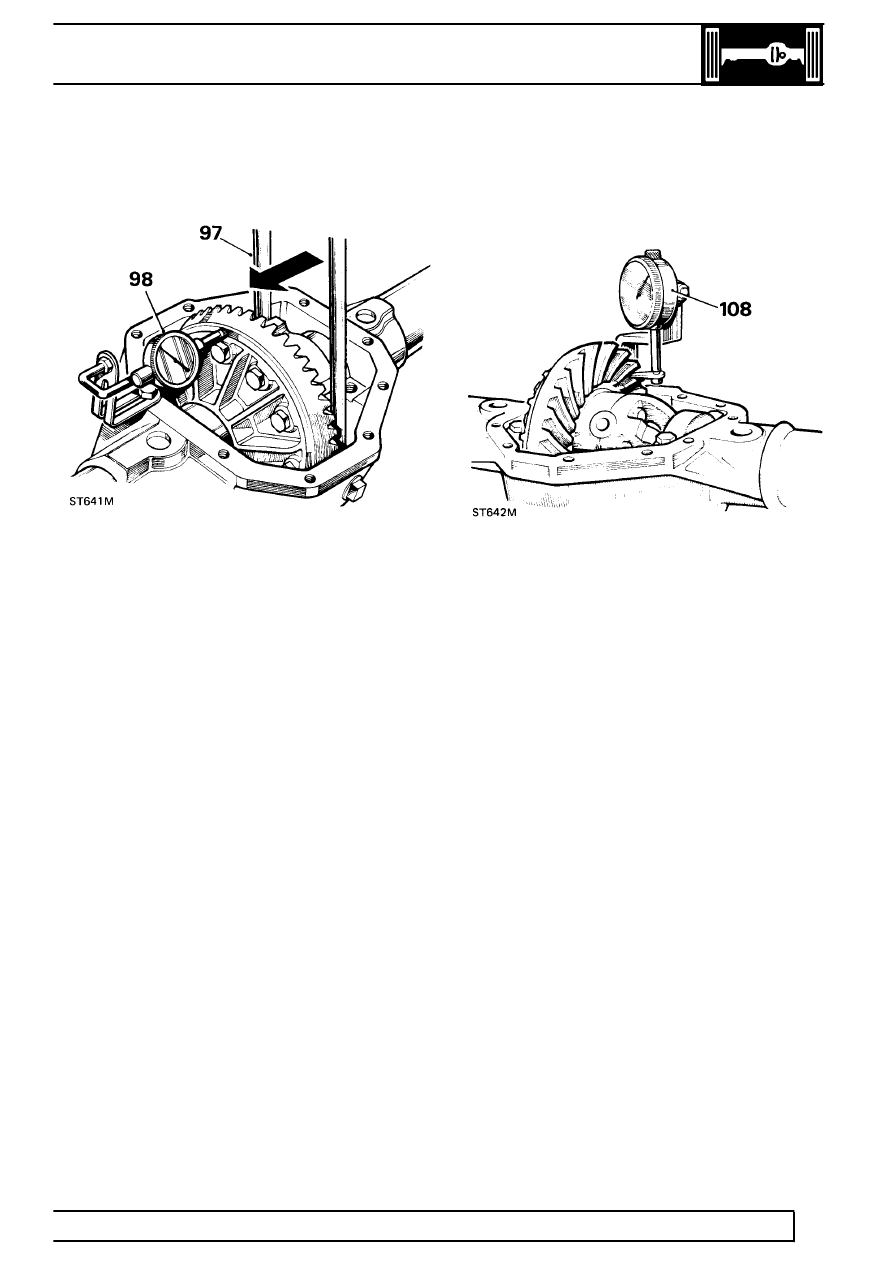

97. Fit differential unit and lever unit away from drive

pinion until opposite bearing cup is seated

against housing. Do not tilt unit.

98. Install a dial gauge on casing with its stylus

resting on back face of crown wheel. Zero the

gauge.

99. Lever differential unit to engage crown wheel

teeth in full mesh with drive pinion teeth. Do not

tilt unit.

100. Note total reading obtained on dial gauge.

101. From this figure subtract 0,25 mm to obtain

correct crown wheel backlash when fitted. The

result indicates value of shimming to be fitted

between differential case and bearing cone at

crown wheel side of differential.

102. Fit shim value determined in instruction 101,

taking shims from pack previously determined

during ’Differential bearing adjustment’ checks,

instructions 57 to 62 LRT-51-500 details 1 and 2,

press LRT-99-002, and LRT-51-504.

103. Fit remaining shims from instruction 101 to

opposite side of differential. LRT-51-501 details

1 and 2, press LRT-99-002, and LRT-51-504.

104. Fit differential unit with shims and bearings to

axle casing, using axle spreader LRT-51-503

with pegs 18G131F.

105. Remove axle spreader.

106. Fit bearing caps in their correct position,

referring to relationship markings on caps and on

axle casing.

107. Tighten bearing caps fixings to

135 Nm (100

lbf/ft).

108. Mount a dial gauge on axle casing with stylus

resting on a crown wheel tooth.

109. Prevent drive pinion from rotating and check

crown wheel backlash which must be 0,15 to

0,27 mm. If backlash is not within specified

limits, repeat differential backlash checks,

instructions 96 to 102 looking for possible errors.

110. Fit differential cover and new gasket, coating

both sides of gasket with Hylomar PL 32M or an

equivalent non-setting sealant. Torque load for

fixings is

30 Nm (22 lbf/ft).

111. Reverse instructions 3 to 5 and coat threads of

hub driving member bolts with Loctite ’Studlock’

grade CVX and fit and tighten bolts evenly to

correct torque.

112. Fit rear axle assembly to vehicle

See Repair,

Rear axle .

113. Replenish differential with recommended

lubricant

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids . After initial axle run,

check oil level and replenish as necessary to

filler/level plug hole.

114. Where major running parts have been replaced

during servicing, it is a recommended practice to

allow axle assembly to ’run in’ by avoiding,

where possible, heavy loads and high speeds

during initial running.