TD5 Defender

12

ENGINE

32

OVERHAUL

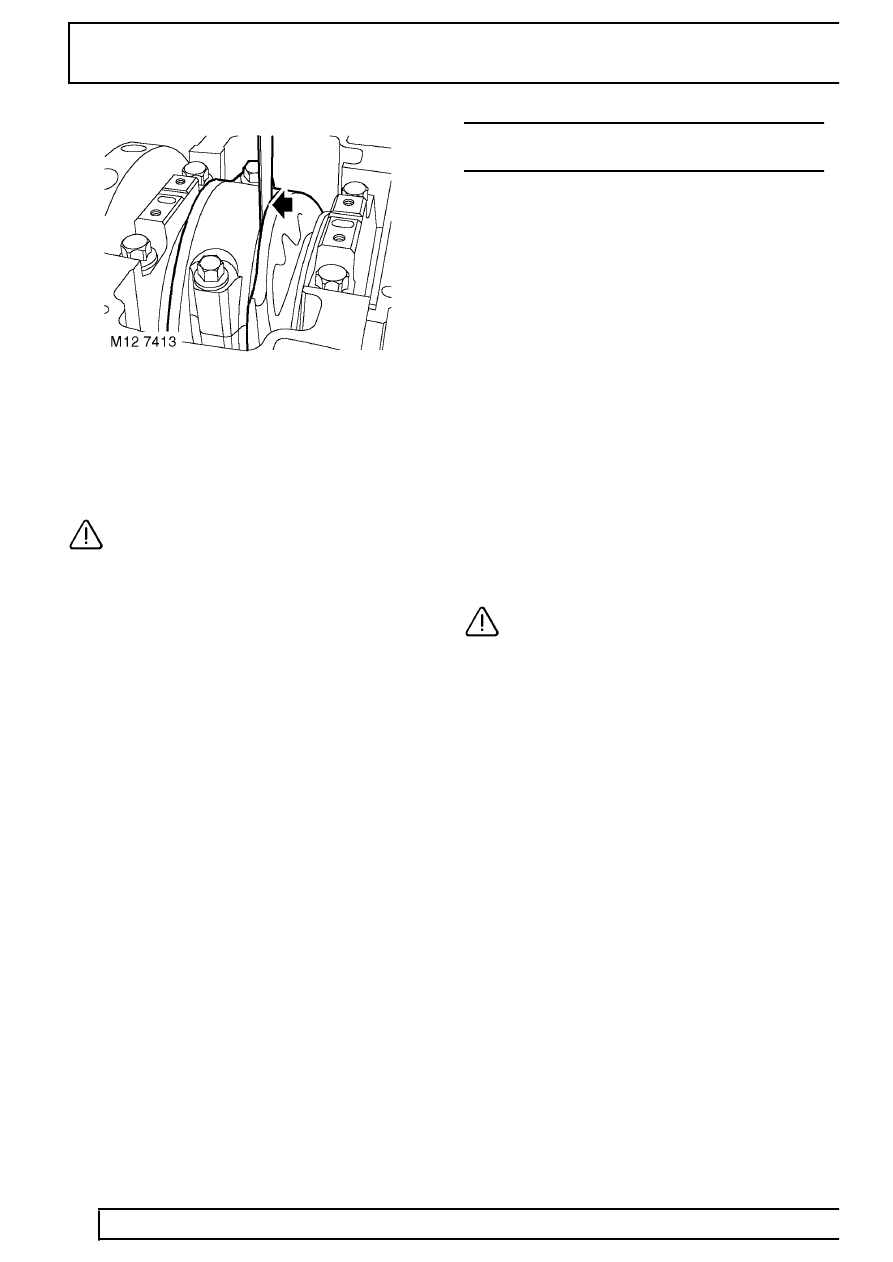

8. Carefully move connecting rod to one side of

journal and using feeler gauges, measure

end-float of connecting rod on journal:

Connecting rod end-float = 0.2 to 0.5 mm

(0.008 to 0.021 in).

CAUTION: If end-float exceeds limits

given, replace connecting rod and repeat

end-float check - See pistons, connecting

rods and cylinder bores.

9. Repeat above procedures for remaining big-end

bearings.

10. Fit oil pump. See this Section.

PISTONS, CONNECTING RODS AND CYLINDER

BORES

Service repair no - 12.17.02.01

Remove

1. Remove cylinder head gasket. See this

Section.

2. Remove connecting rod bearings. See this

Section.

3. Remove ridge of carbon from top of cylinder

bore.

4. Suitably identify each piston and connecting rod

assembly to its respective cylinder bore.

5. Carefully push connecting rod to top of cylinder

bore taking care that connecting rod does not

contact oil squirt jet or cylinder wall, remove

each piston and connecting rod assembly in

turn.

6. Using a suitable expander, remove and discard

piston rings from pistons.

7. Using a squared off end of an old piston ring,

clean carbon from ring grooves.

8. Clean carbon from piston crown and skirt.

CAUTION: Do not use abrasives on

graphited area of piston skirt, do not use a

wire brush or scraper on any part of the

pistons.

9. Secure connecting rod in a soft jawed vice.

10. Suitably identify each piston to its connecting rod

and fitted position of piston on rod.

11. Using suitable circlip pliers, remove and discard

2 circlips securing gudgeon pin.

12. Push gudgeon pin out of piston and connecting

rod; remove piston.

13. Suitably identify each gudgeon pin to its

respective piston.

14. Repeat above procedures for each piston.