TD5 Defender Engine: Connecting Rod Bearings Service Guide

ENGINE

35

OVERHAUL

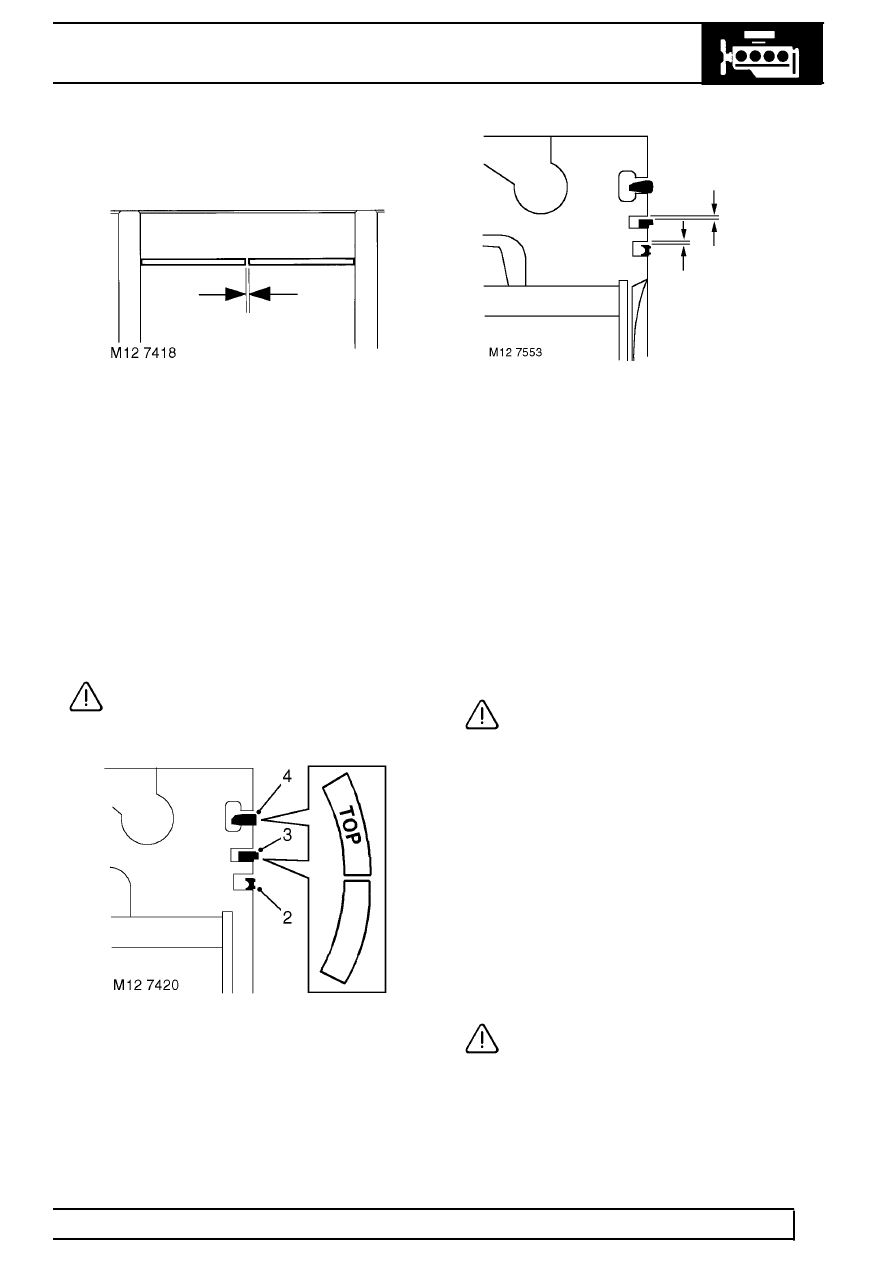

Piston ring gaps - Checking

1. Insert new compression and oil control piston

rings in turn into No. 1 cylinder bore 30 mm (1.25

in) from top of bore and check ring fitted gaps;

ensure rings are kept square to bore when

checking gaps.

1st compression ring fitted gap = 0.30 to 0.40

mm (0.012 to 0.016 in)

2nd compression ring fitted gap = 0.40 to 0.60

mm (0.016 to 0.024 in)

Oil control ring fitted gap = 0.25 to 0.50 mm

(0.01 to 0.02 in)

Repeat for each cylinder bore in turn.

CAUTION: Ensure rings are suitably

identified with the cylinder bore in which

they were checked and are fitted to the

piston for that bore.

2. Fit oil control expander and ring to piston.

3. Fit 2nd compression ring with ’TOP’ marking

upwards.

4. Fit 1st compression ring with ’TOP’ marking

upwards.

5. Check piston ring to groove clearance:

1st compression ring - Not measured

2nd compression ring = 0.050 to 0.082 mm

(0.02 to 0.003 in)

Oil control ring = 0.050 to 0.082 mm (0.02 to

0.003 in)

Pistons and connecting rods - Assembling

1. Lubricate gudgeon pin, gudgeon pin holes in

piston and small-end bush with engine oil.

2. Position piston to its respective connecting rod

with arrow on piston crown on the same side as

the cast boss on the connecting rod.

3. Fit gudgeon pin to its respective piston and

connecting rod; secure with new circlips.

CAUTION: Ensure circlips are fully seated

in their grooves.

4. Repeat above procedures for remaining pistons.

5. Lubricate piston rings and cylinder bores with

engine oil.

6. Check that rings are free to rotate, position ring

gaps at 120

°

to each other and away from the

thrust - LH side of piston - viewed from front of

piston.

7. Using a suitable piston ring clamp, compress

piston rings.

8. Insert connecting rod and piston into its

respective cylinder bore, ensuring that the arrow

on piston crown and the cast boss on connecting

rod are facing towards the front of the cylinder

block.

CAUTION: Ensure that connecting rod

does not contact cylinder bore or oil squirt

jet. Do not pull connecting rod fully down

cylinder bore at this stage.