TD5 Defender

12

ENGINE

18

REPAIR

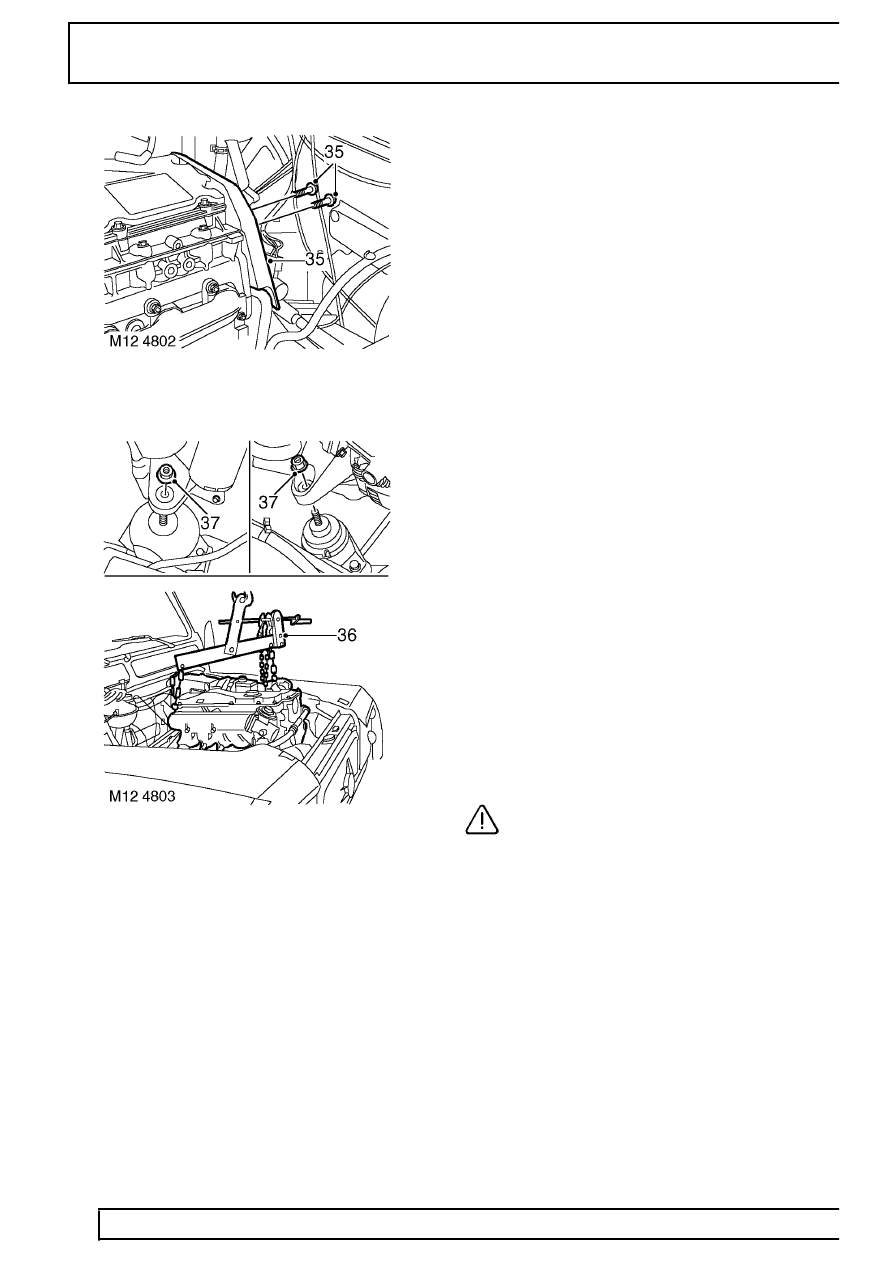

35. Remove 2 bolts and remove acoustic cover from

rear of cylinder head.

36. Fit LRT-12-138 to suitable lifting chains and

connect to lifting eyes on engine.

37. Remove 2 nuts from RH and LH front engine

mountings.

38. Fit trolley jack to support gearbox.

39. With assistance raise chains and remove engine

from vehicle.

Refit

40. With assistance, raise engine from bench and

position in vehicle.

41. With assistance, align engine to gearbox input

shaft.

42. Position 2 upper bolts securing gearbox housing

to engine and tighten to 50 Nm (37 lbf.ft).

43. Lower engine onto mountings and tighten nuts to

85 Nm (63 lbf.ft).

44. Remove LRT-12-138 from engine.

45. Fit and tighten bolt securing engine closing panel

to gearbox.

46. Raise vehicle on ramp.

47. Fit bolts securing gearbox housing to engine and

tighten to 50 Nm (37 lbf.ft).

48. Lower ramp.

49. Fit acoustic cover to rear of cylinder head and

tighten bolts.

50. Position coolant hose to engine oil cooler and

secure clip.

51. Position PAS pump and tighten bolts to 25 Nm

(18 lbf.ft).

52. Position PAS pulley and tighten bolts to 25 Nm

(18 lbf.ft).

53. Position A/C compressor and tighten bolts to 25

Nm (18 lbf.ft).

54. Route engine harness beneath inlet manifold

and connect multiplugs to oil pressure switch,

A/C compressor, and ECT sensor.

55. Fit and tighten bolts securing engine harness to

camshaft carrier.

56. Connect multiplug to alternator.

57. Connect battery lead to alternator and tighten

nut.

58. Clean CKP sensor and mating face.

CAUTION: If originally fitted:- Fit spacer to

CKP sensor.

59. Using a new ’O’ ring, fit CKP sensor, tighten bolt

to 10 Nm (7 lbf.ft) .

60. Connect CKP sensor multiplug.

61. Connect multiplugs to EGR solenoid, inlet

manifold sensor, injector harness, fuel

temperature sensor and CKP sensor.

62. Connect glow plug leads.

63. Connect multiplug to condensor cooling fan.

64. Connect vacuum hose to EGR valve.

65. Connect EGR vacuum hose to vacuum pipe.

66. Position pipe to vacuum pump and secure pipe

to acoustic cover clips.

67. Position fuel cooler. Apply Loctite 242 to bolts

and tighten to 18 Nm (13 lbf.ft).

68. Disconnect fuel hose from connector block and

connect to fuel cooler.

69. Connect fuel hoses to fuel cooler and connector

block on cylinder head.