Discovery II

ENGINE - V8

12-2-70 OVERHAUL

9. Fit gudgeon pin on to centre screw and into

piston bore up to connecting rod.

10. Fit remover/replacer bush LRT-12-126/1 with

flanged end towards gudgeon pin.

11. Screw the stop nut on to centre screw and

position piston against groove of tool LRT-12-

126/2.

CAUTION: Ensure that prongs of tool LRT-

12–126/2 remain in contact with piston and

do not contact gudgeon pin.

12. Lock the stop nut securely with the lockscrew.

13. Lubricate centre screw threads and thrust race

with graphite oil, screw large nut up to tool

LRT-12-013.

14. Set torque wrench to 16 Nm (12 lbf.ft) and using

socket on large nut, pull gudgeon pin in until

flange of remover/replacer bushLRT-12-126/1

is 0.40 mm (0.016 in), dimension 'A' from

face of piston. If torque is exceeded during this

procedure, fit of gudgeon pin to connecting rod

is not acceptable and components must be

replaced.

CAUTION: The centre screw and thrust race

must be kept well lubricated throughout the

operation.

15. Dismantle tool, remove piston and check no

damage has occurred during pressing and that

piston moves freely on gudgeon pin.

16. Remove compression rings, oil control rails

and expander from new piston.

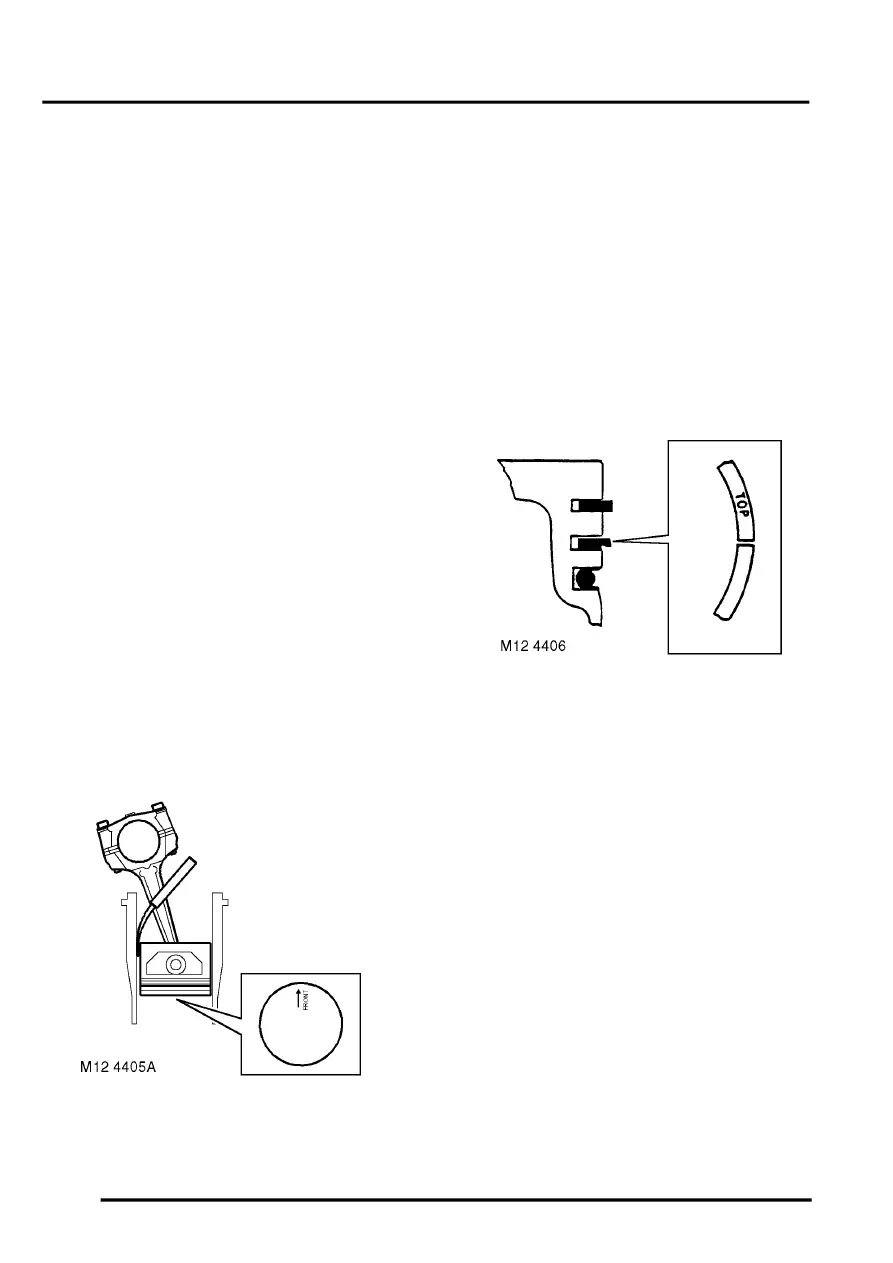

17. Invert piston and with arrow pointing towards

rear of cylinder block, insert piston into cylinder

liner.

18. Position piston with bottom of skirt 30 mm (1.12

in) from top cylinder liner.

19. Using feeler gauges, measure and record

clearance between piston and left hand side of

cylinder- viewed from the front of cylinder

block.

l

Piston to bore clearance = 0.020 to 0.045

mm (0.001 to 0.002 in).

20. Insert piston rings into cylinder bore, use the

piston to hold the rings square to bore and

check the ring gap.

l

1st compression ring = 0.30 to 0.50 mm

(0.012 to 0.02 in).

l

2nd compression ring = 0.40 to 0.65 mm

(0.016 to 0.026 in).

l

Oil control ring rails = 0.38 to 1.40 mm

(0.015 to 0.055 in).

21. Remove piston rings from bore.

22. Fit oil control ring rails and expander, ensuring

ends butt and do not overlap.

23. Fit 2nd compression ring marked 'TOP' with

marking uppermost in 2nd groove.

24. Fit 1st compression ring in first groove either

way round.

25. Check piston ring to groove clearance.

l

1st compression ring = 0.05 to 0.10 mm

(0.002 to 0.004 in).

l

2nd compression ring = 0.05 to 0.10 mm

(0.002 to 0.004 in).

26. Position oil control expander ring joint and ring

rail gaps all at one side, between gudgeon pin

and away from LH side of piston - viewed from

front of piston. Position the gaps in ring rails

approximately 25 mm (1.0 in) each side of

expander ring joint.

27. Position compression rings with gaps on

opposite side of piston between gudgeon pin

and RH side of piston - viewed from front of

piston.

28. Thoroughly clean cylinder bores.

29. Lubricate piston rings and gudgeon pin with

clean engine oil.

30. Lubricate cylinder bore with clean engine oil.