300Tdi Discovery

12

ENGINE

6

REPAIR

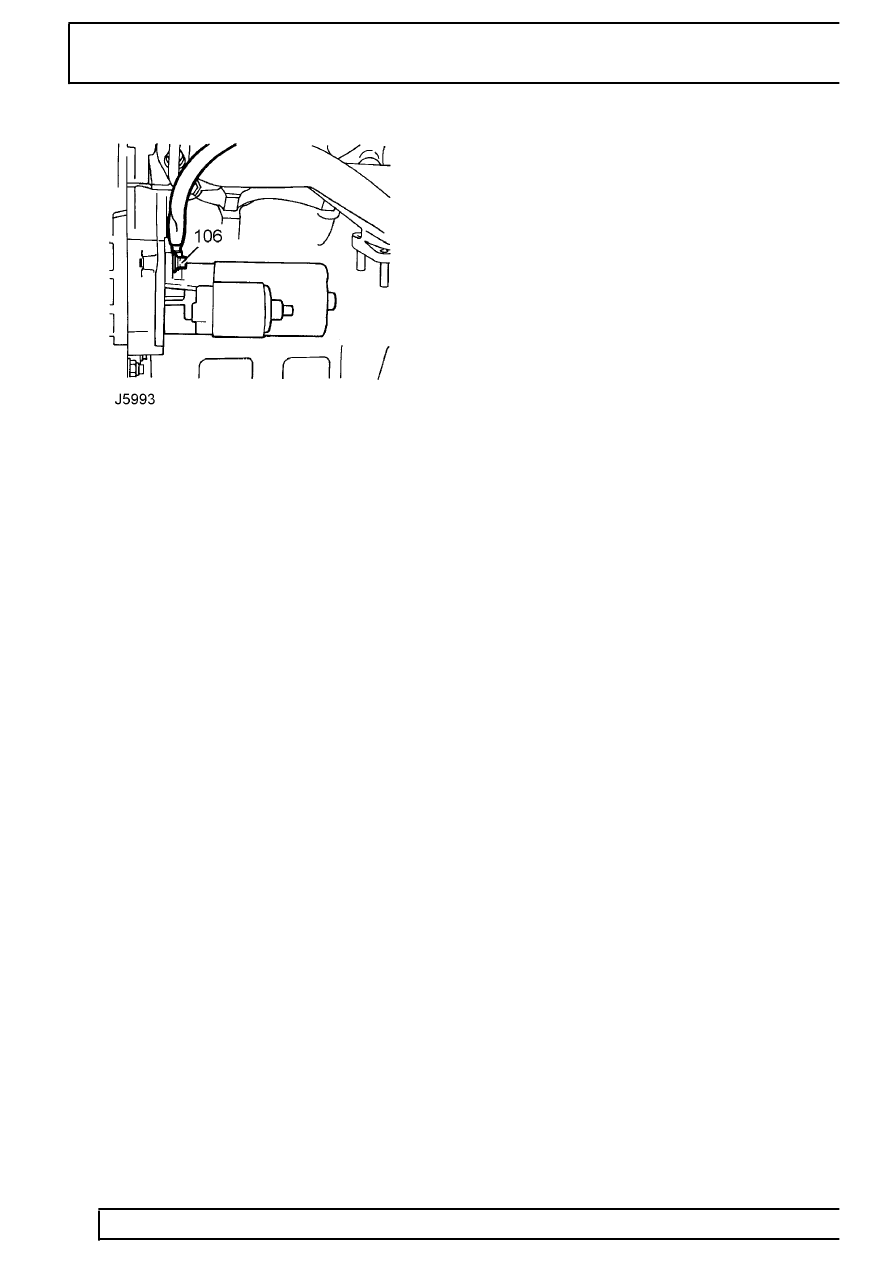

106. Remove top starter bolt securing engine earth

cable.

107. Remove nut securing kick-down cable clip to LH

cylinder head.

108. With assistance, raise engine, move aside all

pipes and wires. Move engine clear of vehicle.

109. Lower engine onto bench.

Refit

110. Clean engine and gearbox mating faces.

111. Clean dowel and dowel holes.

112. With assistance raise engine off bench. Lower

and guide engine into engine compartment

ensuring no wires or pipes become trapped.

113. Position clip securing kick-down cable to LH

cylinder head.

114. Fit and tighten nut.

115. Position engine earth cable and secure to starter

with top bolt. Tighten to

45 Nm.

116. Lower engine.

117. With assistance, engage engine with gearbox.

118. Fit 3 bottom bell housing bolts. Tighten to

46

Nm.

119. Lower jack supporting gearbox.

120. Lower engine onto mounting brackets.

121. Fit centre RH bell housing bolt.

122. Fit centre LH bell housing bolt.

123. Fit harness brackets to 2 top bell housing bolts.

124. Fit bolts. Tighten to

46 Nm.

125. Remove plugs from tranmission and oil cooler

pipe.

126. Clean pipe, lubricate NEW ’O’ ring and fit to

pipe.

127. Connect pipe to transmission and secure with

union. Tighten to

30 Nm.

128. Align pipe bracket to sump, position spacer and

fit bolt. Tighten to

18 Nm.

129. Fit heatshield and secure with nut.

130. Secure transducer lead to clip on heatshield.

131. Slacken bell housing access plate bolt.

132. Move plate aside.

133. Remove block.

134. Align drive plate and torque converter.

135. Fit 2 torque converter bolts.

136. Rotate engine and fit second 2 bolts. Tighten to

45 Nm.

137. Rotate engine and tighten first 2 bolts to Tighten

to

45 Nm.

138. Clean cover plate and mating face.

139. Position cover plate and fit bolts. Tighten to

45

Nm.

140. Position access plate.

141. Fit 2 remaining bolts and tighten all bolts to

Tighten to

9 Nm.

142. Position engine harness around engine.

143. Connect knock sensor multiplug.

144. Connect starter solenoid Lucar.

145. Position starter motor heatshield and secure clip

to solenoid.

146. Align shield bracket to engine mounting bracket

and fit bolt. Tighten to

9 Nm.

147. Clean crankshaft sensor mating faces.

148. Position sensor and connect multiplug.

149. Position/align sensor and shield to backplate. Fit

bolts. Tighten to

6 Nm.

150. Fit tie bar, align to transmission and fit bolts.

Tighten to

25 Nm.

151. Fit tie bar securing nut. Tighten to

45 Nm.

152. Fit catalytic converter/front pipe assembly.

See

EMISSION CONTROL, Repair, Catalytic

Converter/Front Pipe - 4.0 V8

153. Raise engine.

154. Fit RH mounting rubber.

155. Move engine over.

156. Fit LH mounting rubber.

157. Lower engine.

158. Disconnect hoist.

159. Fit engine mounting nuts. Tighten to

55 Nm.

160. Remove plugs from steering pump and steering

box.

161. Clean PAS hose unions.

162. Lubricate ’O’ rings and fit to hose unions.

163. Position hose.

164. Align unions to pump and steering box. Tighten

14mm thread to

15 Nm , 16mm thread to

Tighten to

20 Nm.

165. Remove plugs from feed hose and PAS pump.

166. Connect hose to pump and tighten clip.

167. Untie compressor and position to engine

bracket.

168. Position heatshield and fit bolts. Tighten to

25

Nm.

169. Connect compressor multiplug.

170. Position drive belt.