Depressurising Fuel System on 300Tdi Discovery 19: MFI Repair

19

FUEL SYSTEM

6

REPAIR

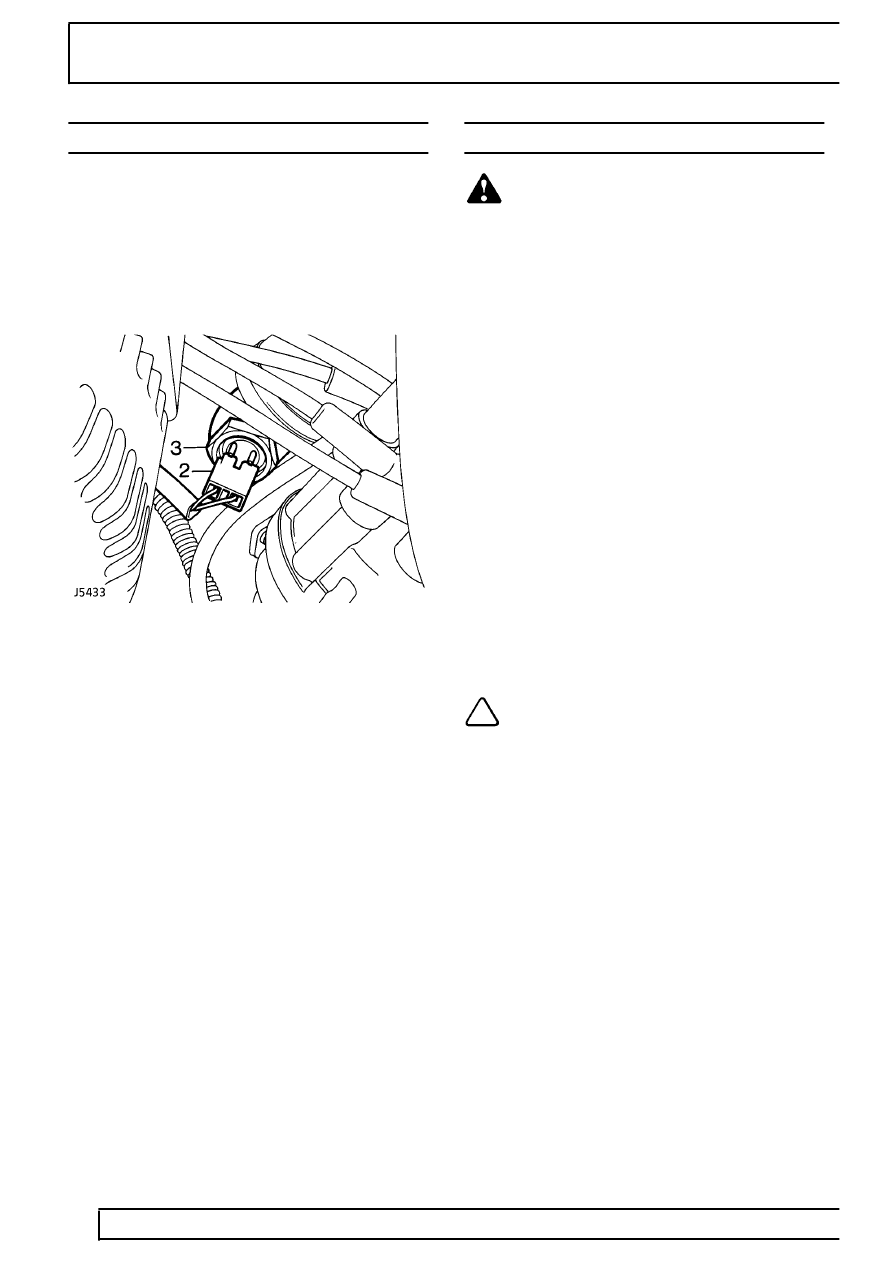

ENGINE COOLANT TEMPERATURE SENSOR

Service repair no - 19.22.18

Remove

1. Position drain tray to collect coolant spillage.

2. Disconnect multiplug from coolant sensor.

3. Remove sensor from thermostat housing.

4. Remove and discard copper washer.

Refit

5. Fit a new copper washer.

6. Fit sensor and tigten securely.

7. Top-up cooling system.

8. Run engine, check for water leaks around

sensor.

DEPRESSURISING FUEL SYSTEM

WARNING: Under normal operating

conditions the Multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

1. Remove fuel pump relay module.

See

Multiport Fuel Injection Relays

2. Start and run engine.

3. When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4. Disconnect battery negative lead.

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel feed

hose at fuel rail.

5. Disconnect either:

a) Nut and olive at fuel rail

OR

b) Hose at inlet end of fuel filter.

Refit

6. Refit fuel feed hose.

7. Refit fuel pump relay module, reconnect battery.

8. Crank engine (engine will fire in approximately 6

to 8 seconds).