300Tdi Discovery

Tdi

13

REPAIR

Refit

21. Remove blanks from pump.

22. Remove special tool pin from pump.

23. Clean mating faces of pump and front cover.

24. Fit pump to cover with a new gasket and secure

with nuts. Tighten to

25 Nm.

25. Attach pump to bracket and finger tighten nuts

and bolts

26. First tighten bolts securing bracket to block and

then bolts securing pump to bracket.

27. Connect spill return, main fuel pipes. Tighten to

25 Nm.

28. Connect boost signal pipe and secure with banjo

bolts. Tighten to

10 Nm.

29. Connect stop control solenoid lead.

30. Connect throttle cable and where applicable

hand throttle cable.

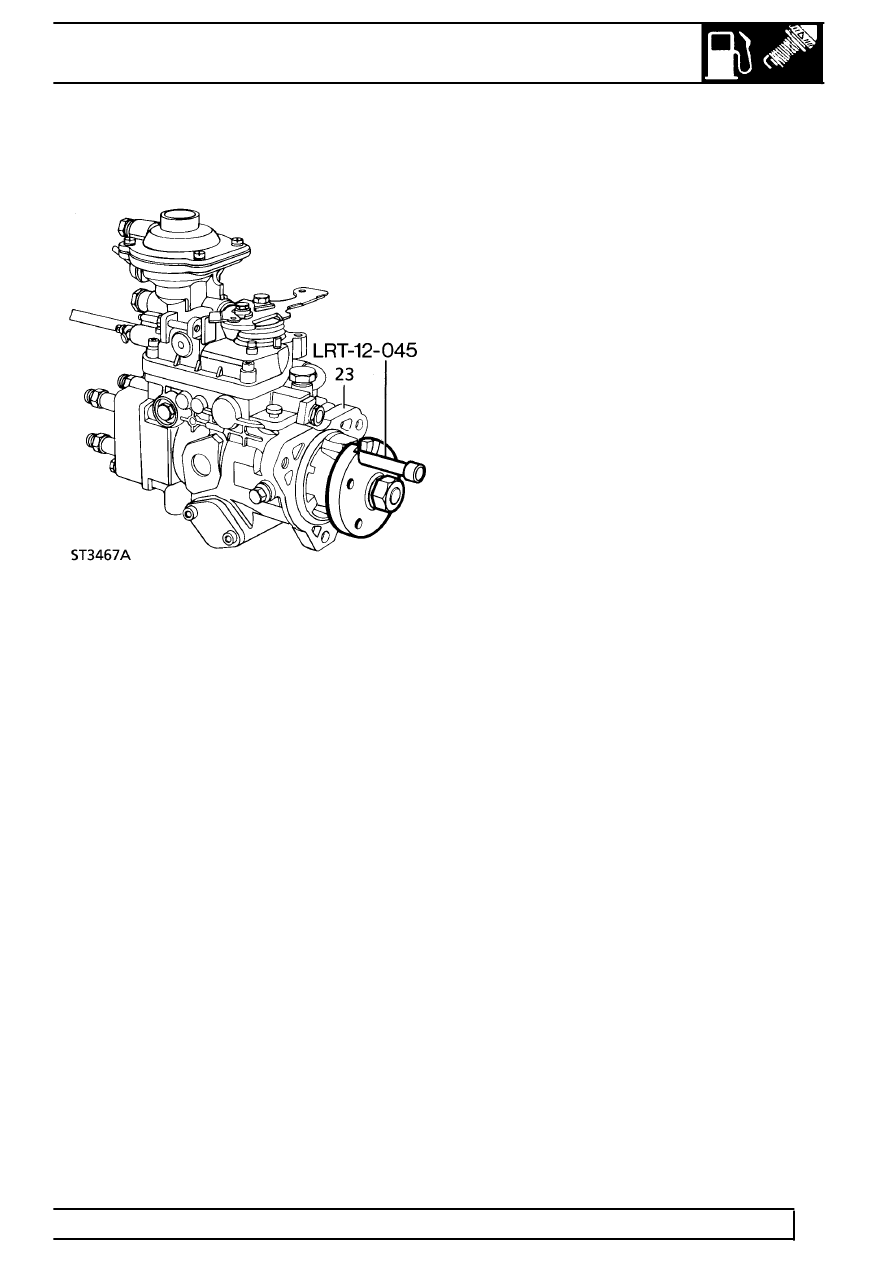

31. Remove special tool LRT-12-045.

32. Fit gear lock plate.

33. Fit pin from special tool LRT-12-045.

34. Secure gear with bolts.

35. Remove special tool pin.

36. Turn crankshaft two complete revolutions, check

timing pin from LRT-12-045 can be fully and

easily inserted into the pump. At the same time

check flywheel timing pin LST-12-044 can also

be inserted in the flywheel slot.

37. If, with the flywheel timing pin located, the timing

pin cannot be inserted cleanly into the injection

pump, carry out the following:

(a)

Ensure flywheel timing pin is disengaged

from slot in flywheel.

(b)

Turn the crankshaft the small amount

necessary to enable the timing pin to be

inserted into the pump.

(c)

Loosen the three pump gear retaining

bolts.

(d)

Turn the crankshaft to T.D.C..

(e)

Check that the timing pin is an easy fit in

the pump and that the flywheel timing pin

locates.

(f)

Tighten the pump gear retaining bolts to

the correct torque.

(g)

Remove the timing pin from the pump and

the timing tool from the flywheel housing.

38. Using antisieze compound, fit the blanking plug

to flywheel housing. Tighten to

12 Nm.

39. Fit access plate with gasket to front cover plate.

Tighten to

25 Nm.

40. Refit injector pipes. Tighten to

29 Nm.