Freelander Service Procedures

DRIVESHAFTS

47-4

REPAIRS

12. Remove 2 bolts securing damper to hub.

13. Release hub from damper.

14. Release drive shaft from hub.

15. Position container to catch oil spillage.

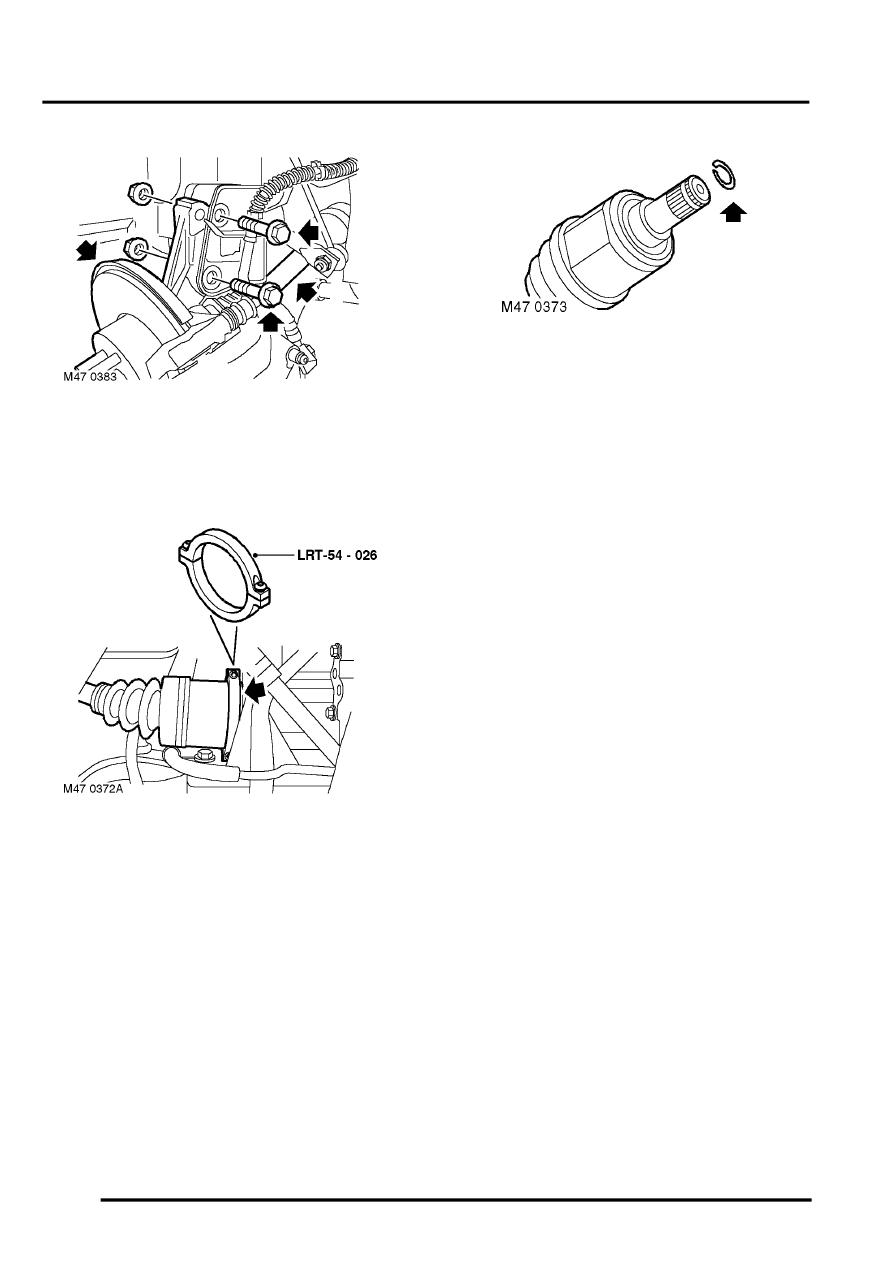

16. Secure LRT-54-026 to drive shaft inboard joint.

Using a lever, release drive shaft from gearbox.

17. Remove drive shaft.

CAUTION: Care must be taken not to

damage oil seal when removing drive shaft

from gearbox

18. Remove and discard circlip from drive shaft.

Refit

1. Inspect gearbox seal for signs of wear or

damage.

2. Wipe drive shaft ends, gearbox oil seal and

hub.

3. Lubricate oil seal running surfaces.

4. Fit new circlip to drive shaft.

5. Fit drive shaft ensuring circlip is fully engaged.

CAUTION: Drive shaft must be fitted with

care to prevent damage to gearbox oil seal.

6. Position drive shaft in hub.

7. Fit new hub nut but do not tighten at this stage.

8. Fit hub to damper, fit nuts and bolts and tighten

to 205 Nm (150 lbf.ft).

9. Position caliper to brake disc fit bolts and

tighten to 100 Nm (74 lbf.ft).

10. Clean ABS sensor and mating face.

11. Lubricate ABS sensor with anti-seize grease.

12. Fit ABS sensor .

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

reluctor ring.

13. Position ABS harness and brake hose in

bracket and secure with clip.

14. Fit splash shield and secure with bolts.

15. Tighten front hub nut to 400 Nm (295 lbf.ft).

16. Stake front hub nut.

17. Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

18. Check and top up oil level as required.

Intermediate Reduction Drive - Non NAS

models.

19. Fit underbelly panel.

20. Remove stands and lower vehicle.

21. Connect battery earth lead.