Freelander Service Procedures

GENERAL INFORMATION

03-8

Ball and roller bearings

General

When removing and installing bearings, ensure that

the following practices are observed to ensure

component serviceability:

l

Remove all traces of lubricant from the bearing

under inspection by cleaning with a suitable

degreasant; maintain absolute cleanliness

throughout operations.

l

Conduct a visual inspection for markings on

rolling elements, raceways, outer surface of

outer rings or inner surface of inner rings. Reject

any bearings found to be marked, since marking

in these areas indicates onset of wear.

l

Hold inner race of bearing between finger and

thumb of one hand and spin outer race to check

that it revolves absolutely smoothly. Repeat,

holding outer race and spinning inner race.

l

Rotate outer ring gently with a reciprocating

motion, while holding inner ring; feel for any

check or obstruction to rotation. Reject bearing

if action is not perfectly smooth.

l

Lubricate bearing with generous amounts of

lubricant appropriate to installation.

l

Inspect shaft and bearing housing for

discoloration or other markings which indicate

movement between bearing and seatings.

l

Ensure that shaft and housing are clean and

free from burrs before fitting bearing.

l

If one bearing of a pair shows an imperfection, it

is advisable to replace both with new bearings;

an exception could be if the faulty bearing had

covered a low mileage, and it can be

established that damage is confined to only one

bearing.

l

Never refit a ball or roller bearing without first

ensuring that it is in a fully serviceable condition.

l

When hub bearings are removed or displaced,

NEW bearings must be fitted; do not attempt to

refit the old hub bearings.

l

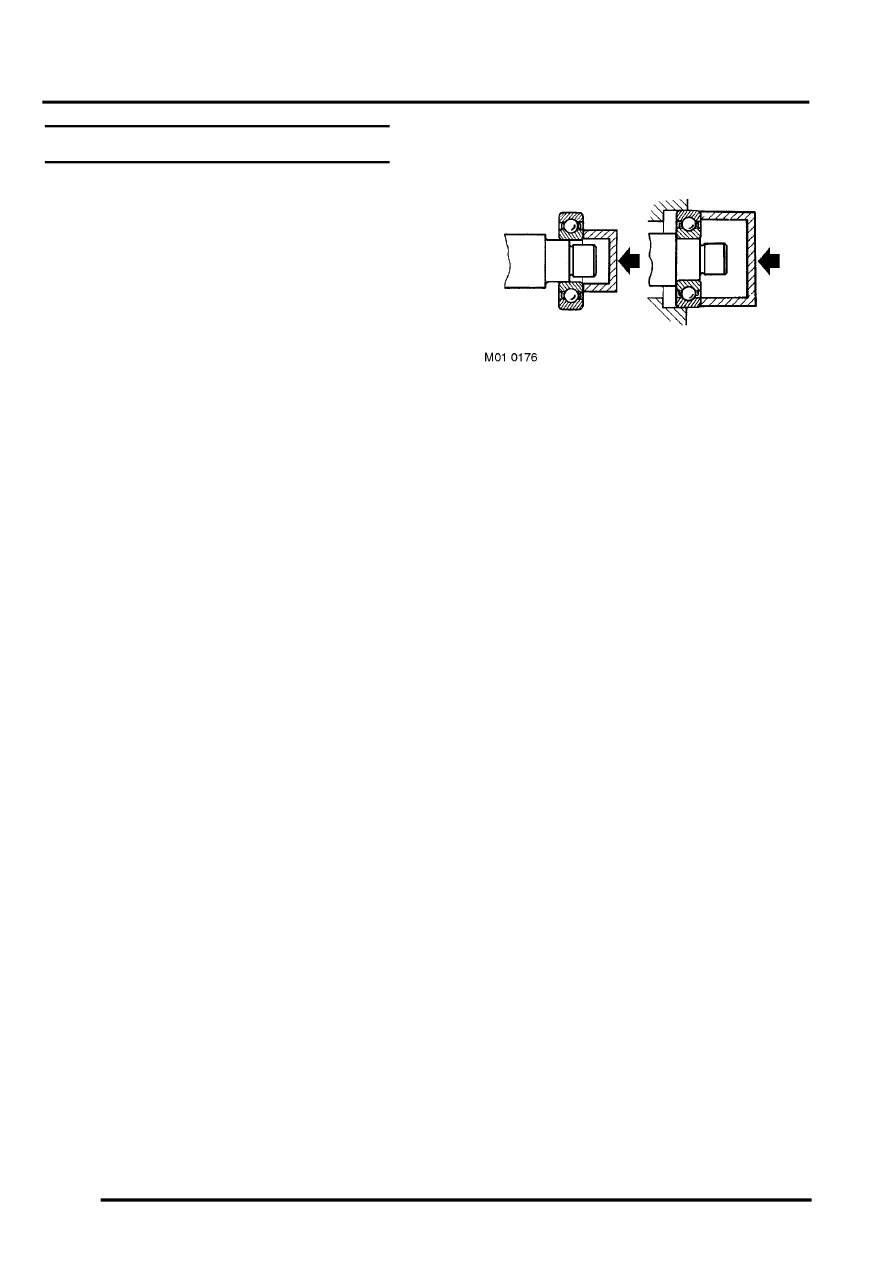

When fitting a bearing to a shaft, only apply

force to the inner ring of the bearing. When

fitting a bearing into a housing, only apply force

to the outer ring of the bearing.

l

In the case of grease lubricated bearings (e.g.

hub bearings) fill the space between bearing

and outer seal with the recommended grade of

grease before fitting seal.

l

Always mark components of separable bearings

(e.g. taper roller bearings) when dismantling, to

ensure correct reassembly. Never fit new rollers

in a used outer ring; always fit a complete new

bearing assembly.