Freelander Safety Precautions for Supplementary Restraint System

GENERAL INFORMATION

03-21

It should be noted that these precautions are not

restricted to operations performed when servicing

the SRS system, the same care should be exercised

when working on ancillary systems and components

located in the vicinity of SRS components; these

include but are not limited to:

l

Steering system – steering wheel airbag,

rotary coupler.

l

Front fascia – passenger front airbag (where

fitted); SRS DCU behind centre console, on

transmission tunnel under the HeVAC system.

l

Front seats – seat belt pre-tensioners, integral

with seat belt buckle assembly.

l

Electrical system – SRS harnesses, link leads

and connectors.

Making the SRS system safe

Before working on or in the vicinity of SRS

components, ensure the system is rendered safe by

performing the following procedures:

l

Remove the ignition key from the ignition switch.

l

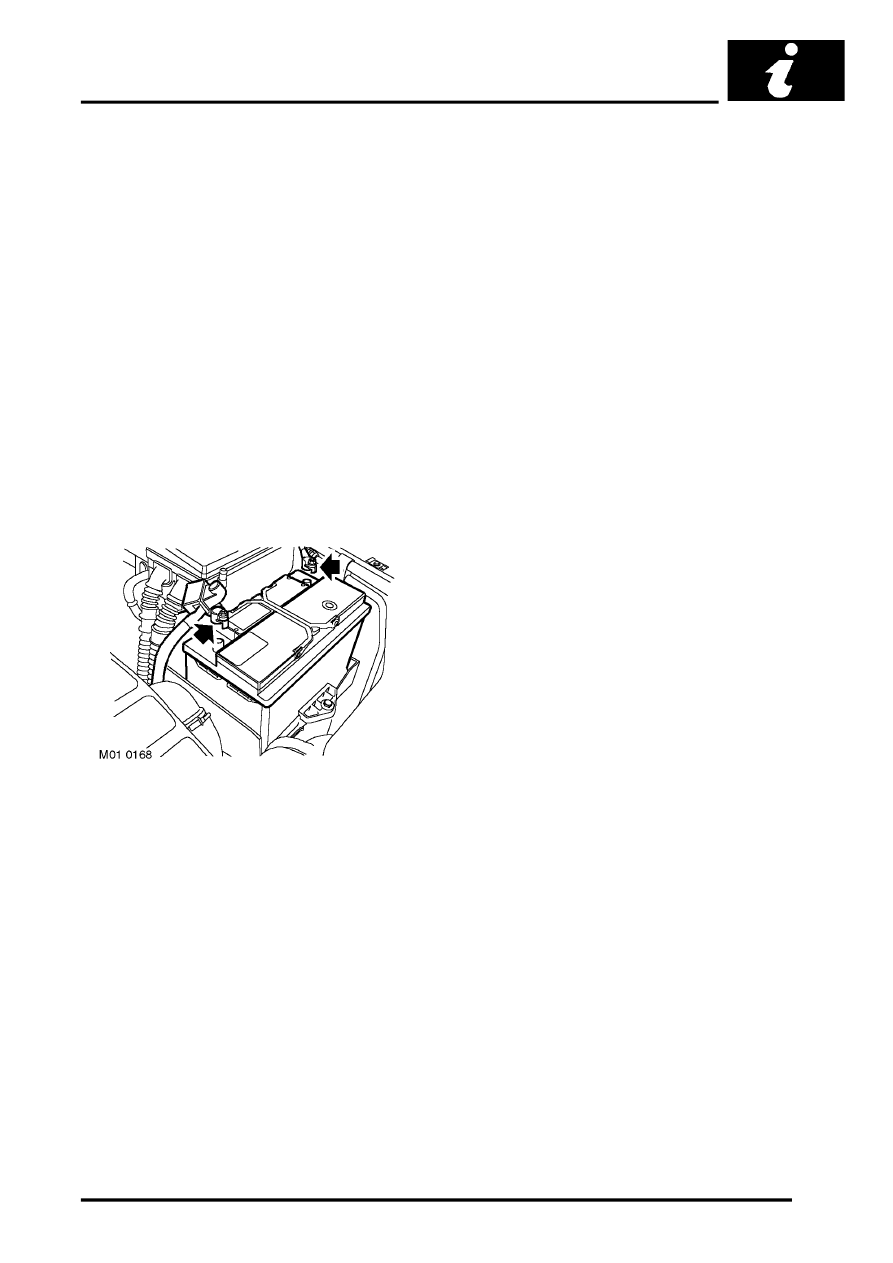

Disconnect both battery leads, earth lead first.

l

Wait 10 minutes for the SRS DCU back-up

power circuit to discharge.

The SRS system uses energy reserve capacitors

that keep the system active in the event of electrical

supply failure under crash conditions. It is necessary

to allow the capacitor sufficient time to discharge (10

minutes) in order to avoid the risk of accidental

deployment.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Installation

In order to assure system integrity, it is essential that

the SRS system is regularly checked and maintained

so that it is ready for effective operation in the event

of a collision. Carefully inspect SRS components

before installation. Do not install a part that shows

signs of being dropped or improperly handled, such

as dents, cracks or deformation.

WARNING: The integrity of SRS system

components is critical for safety reasons. Ensure

the following precautions are always adhered to:

l

Never install used SRS components from

another vehicle or attempt to repair an SRS

component.

l

When repairing an SRS system only use

genuine new parts.

l

Never apply electrical power to an SRS

component unless instructed to do so as

part of an approved test procedure.

l

Special Torx bolts are necessary for

installing the airbag module — do not use

other bolts. Ensure bolts are tightened to the

correct torque.

l

Always use new fixings when replacing an

SRS component.

l

Ensure the SRS Diagnostic Control Unit

(DCU) is always installed correctly. There

must not be any gap between the DCU and

the bracket to which it is mounted. An

incorrectly mounted DCU could cause the

system to malfunction.

CAUTION: Ensure SRS components are not

contaminated with oil, grease, detergent or

water.

Ensure that SRS component fixings are correctly

positioned and torqued during service and repair.

CAUTION: Torque wrenches should be regularly

checked for accuracy to ensure that all fixings

are tightened to the correct torque.

If you suspect an airbag assembly could be

defective, install a new unit and dispose of the old

unit. Manually deploy the old unit before disposal.