Freelander Service Procedures

INTERMEDIATE REDUCTION DRIVE

REPAIRS

41-21

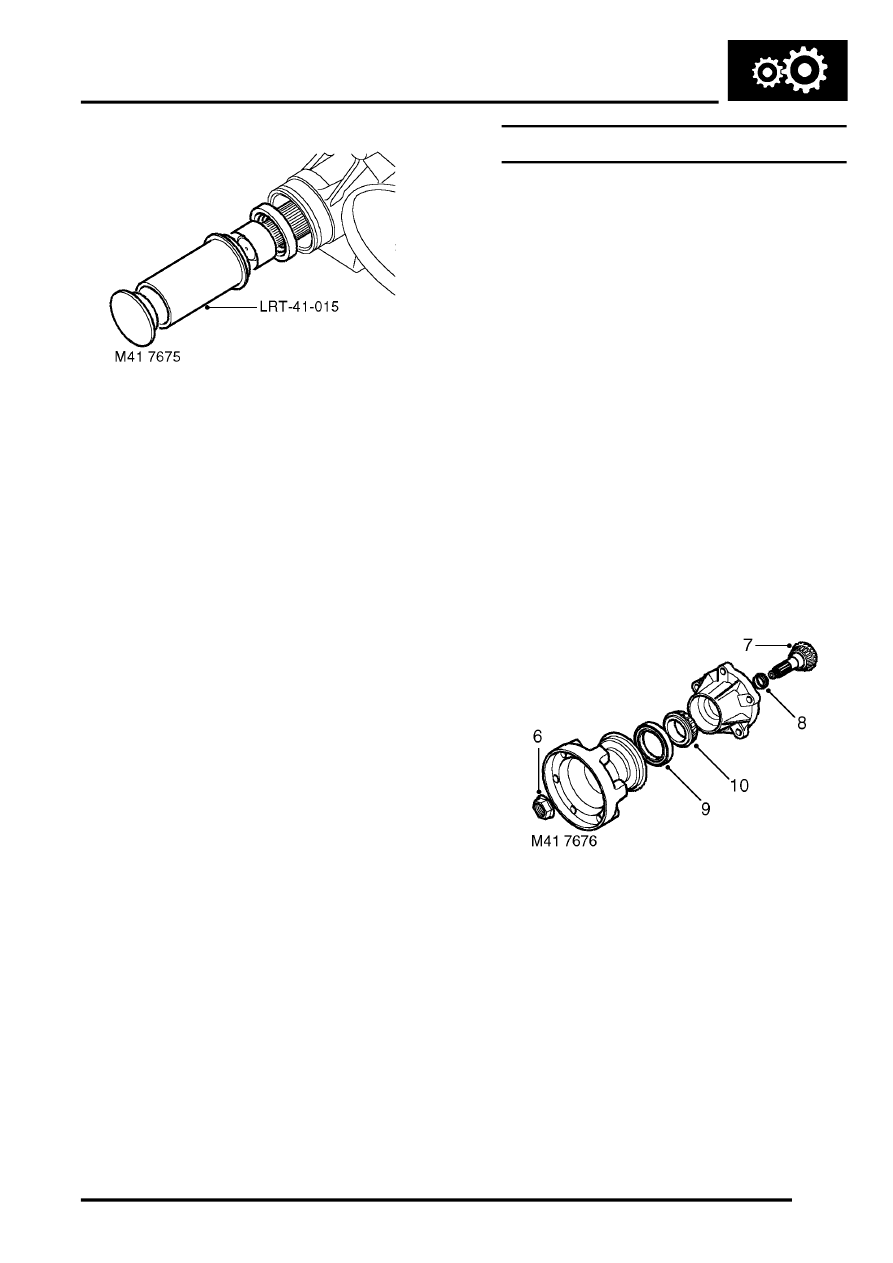

12. Using flanged end of LRT-41-015 fit outer seal

to depth dictated by tool flange.

CAUTION: Use end protector of LRT-41-015

to avoid damage to the working surfaces of

the tool.

13. Remove oil seal protector.

14. Fit IRD.

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - K1.8.

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

Seal - pinion gear

$% 41.29.04

Remove

1. Remove pinion housing.

DRIVE, REPAIRS, Seal - pinion gear

housing - Td4.

DRIVE, REPAIRS, Seal - pinion gear

housing - K1.8.

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - Non NAS.

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - NAS.

CAUTION: Before dismantling the pinion

housing, measure the turning torque on

existing bearings.

2. Attach pinion housing to suitable mounting

plate and secure mounting plate in vice.

3. Check pinion torque to turn figure.

4. Reference mark pinion flange and pinion shaft

for assembly purposes.

5. Restrain pinion flange using LRT-51-003.

6. Remove and discard nut.

7. Position pinion housing onto press, fit suitable

adaptor on end of pinion shaft, press pinion

shaft from drive flange and housing.

8. Remove and discard collapsible spacer.

9. Using a suitable lever, remove pinion oil seal.

CAUTION: Take care to avoid damage to oil

seal recess.

10. Remove pinion bearing inner race.