Range Rover P38

12

ENGINE

NEW RANGE ROVER

28

REPAIR

Piston Protrusion - Check

34. Ensure cylinder block face and piston crowns

are clean.

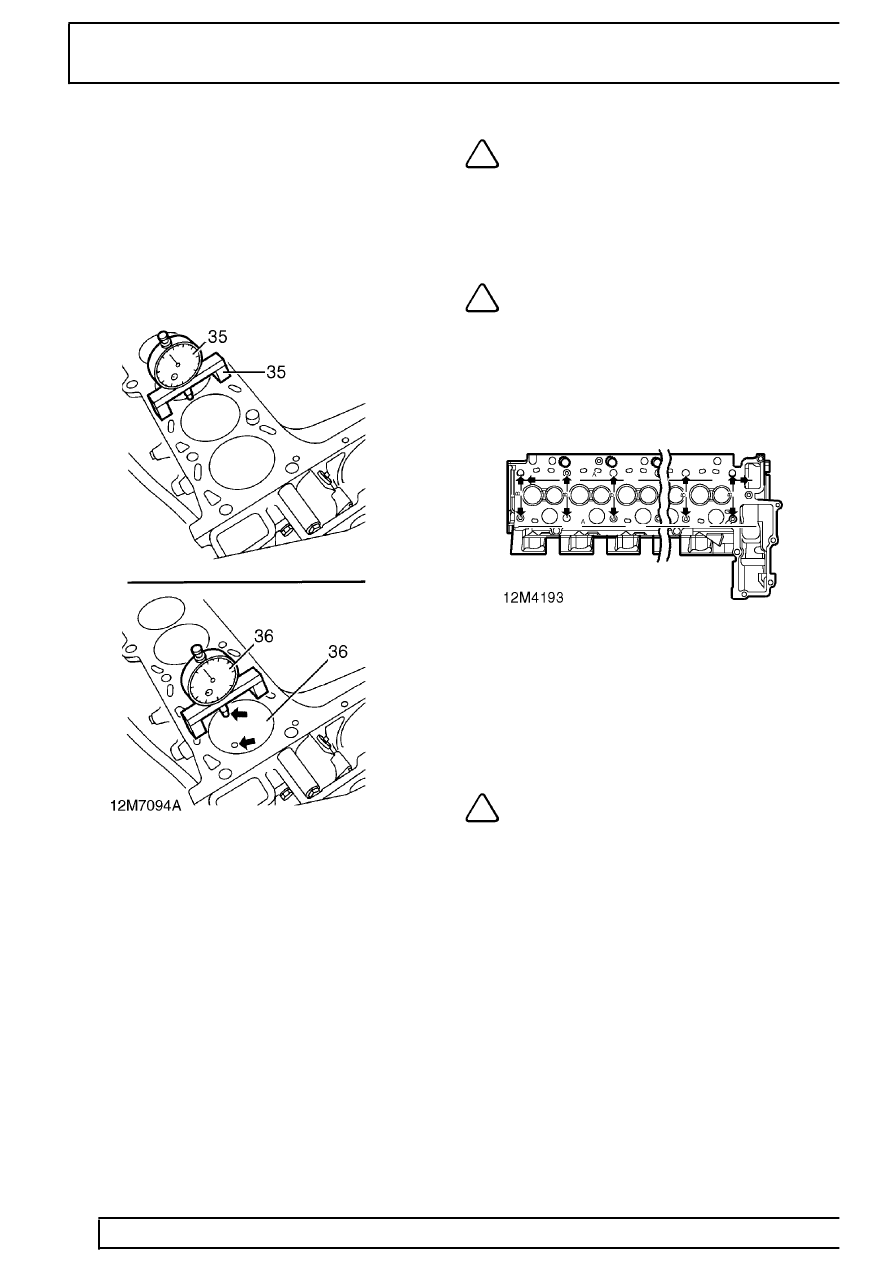

35. Position a dial gauge with suitable base to

cylinder block.

36. Preload and zero gauge on cylinder block face.

37. Move gauge onto piston crown. Measure

protrusion of No. 1 piston in two positions as

shown. Take average of readings. Record

results.

38. Repeat protrusion check on piston No. 6.

39. Remove timing pin LRT-12-108 from flywheel.

40. Record protrusion of remaining pistons. Ensure

that readings are taken at exactly TDC.

NOTE: Top Dead Centre must be located

using dial gauge.

41. Calculate average piston protrusion to determine

required gasket thickness:

Up to 0.76 mm = 2 identification holes

Over 0.76 mm = 3 identification holes

NOTE: If any piston protrudes more then

0.81mm, a gasket with 3 identification

holes must be fitted.

Cylinder head warp - check

42. Remove all traces of carbon and gasket material

from cylinder head.

43. Using a straight edge and feeler gauges, check

cylinder head for distortion along lines shown in

illustration and compare with figures given:

Longitudinal warp A = 0.1 mm (0.004 in)

Lateral warp B = 0.05 mm (0.002 in)

44. Replace cylinder head if figures obtained exceed

those given.

NOTE: Cylinder heads may not be refaced.