Range Rover P38

BMW DIESEL

29

REPAIR

Refit

CAUTION: If crankshaft timing pin

LRT-12-108 has been removed, ensure that

FIP is on correct stroke, with dimple on

FIP sprocket visible, before refitting pin.

45. Ensure all mating faces are clean.

46. Check cylinder block ring dowels for condition

and correct location.

47. Apply 1.5mm bead of Unipart sealant STC 3373

to joint lines of cylinder block and timing cover.

48. Fit cylinder head gasket of correct thickness.

49. Fit tool LRT-12-112 to ensure camshaft is in

correct position. If necessary, turn camshaft

using spanner on cast hexagon.

CAUTION: Do not turn camshaft if cylinder

head is fitted to cylinder block.

NOTE: Fit a lightly oiled, new cylinder

head bolt in LH rear location.

50. Position cylinder head on cylinder block. Ensure

timing chain guide is not fouled and rear LH bolt

enters bolt hole in cylinder block. Locate cylinder

head on ring dowels.

51. Disconnect lifting chains. Remove lifting eye.

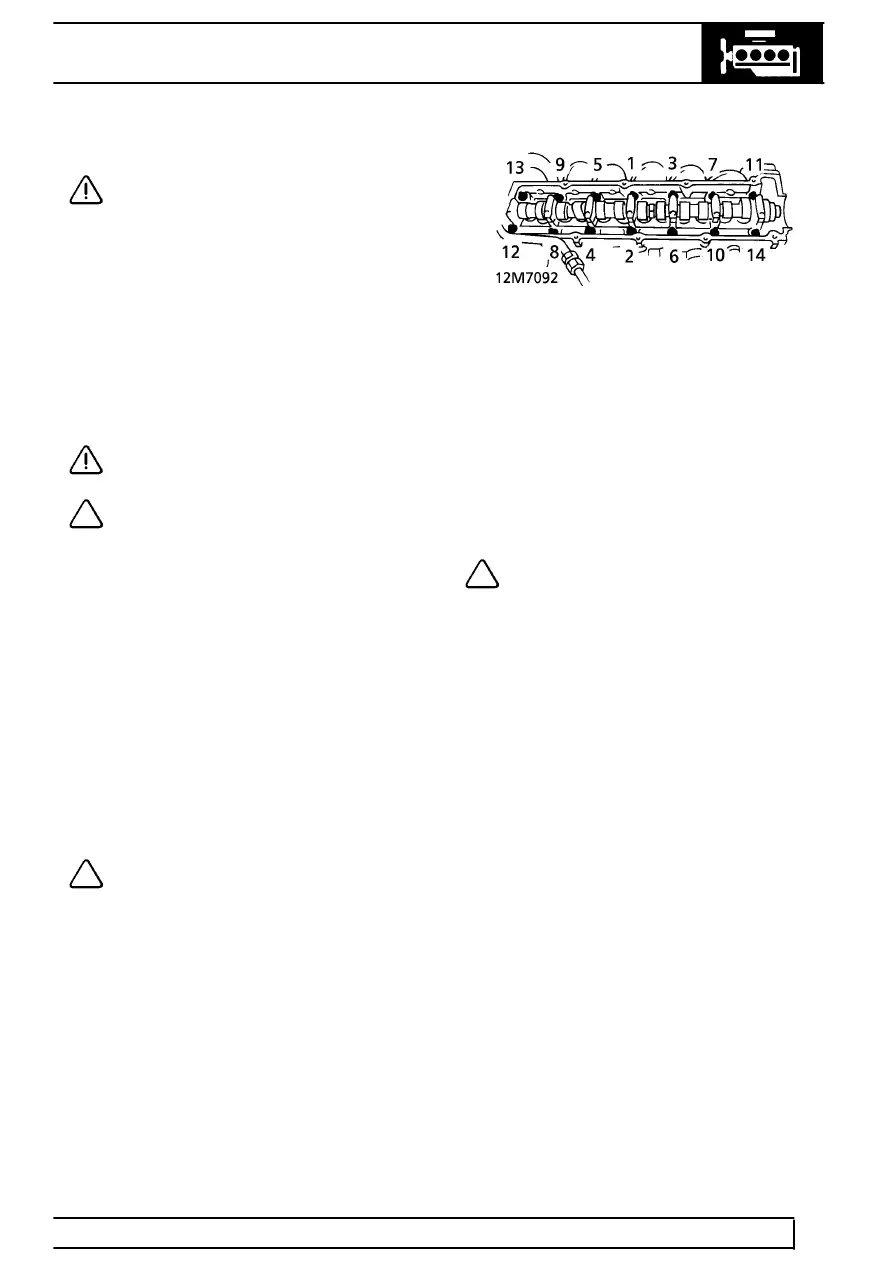

52. Lightly lubricate new cylinder head bolts. Fit

bolts. Tighten, in sequence shown, in the

following stages.

Stage 1 = 80 Nm (59 lbf.ft)

Stage 2 = Loosen by 180

°

Stage 3 = 50 Nm (37 lbf.ft)

Stage 4 = Tighten 90

°

Stage 5 = Tighten 90

°

Stage 6 = Run engine for 25 minutes

Stage 7 = Stop engine, allow to cool

Stage 8 = Tighten 90

°

NOTE: Tighten using angular torque

wrench.

53. Secure cylinder head to timing cover with bolts

and nut.

M7 -

15 Nm (11 lbf.ft)

M8 -

20 Nm (15 lbf.ft)

54. Fit camshaft timing chain tensioner rail.

55. Using new ’O’ rings, fit tensioner and guide rail

pins.

56. Engage timing chain with camshaft sprocket.

Position sprocket on camshaft.

57. Fit NEW camshaft sprocket bolt.

NOTE: Important; if engine has covered

more than 20,000 km (12,500 miles), insert

a feeler gauge of 4.61 mm (0.18 in)

thickness between cylinder head face and inlet

manifold side of LRT-12-112 prior to tightening

bolt.

58. With LRT-12-112 fitted to camshaft, tighten

camshaft sprocket bolt to

20 Nm (15 lbf.ft).

59. Using a suitable torque angle gauge, further

tighten bolt by 35

°

.

60. Remove LRT-12-112.

61. Using tool LRT-12-115, lever tensioner rail to

slack position. Remove LRT-12-114 from

tensioner plunger.

62. Using a new sealing washer, refit access plug.