Range Rover P38

BMW DIESEL

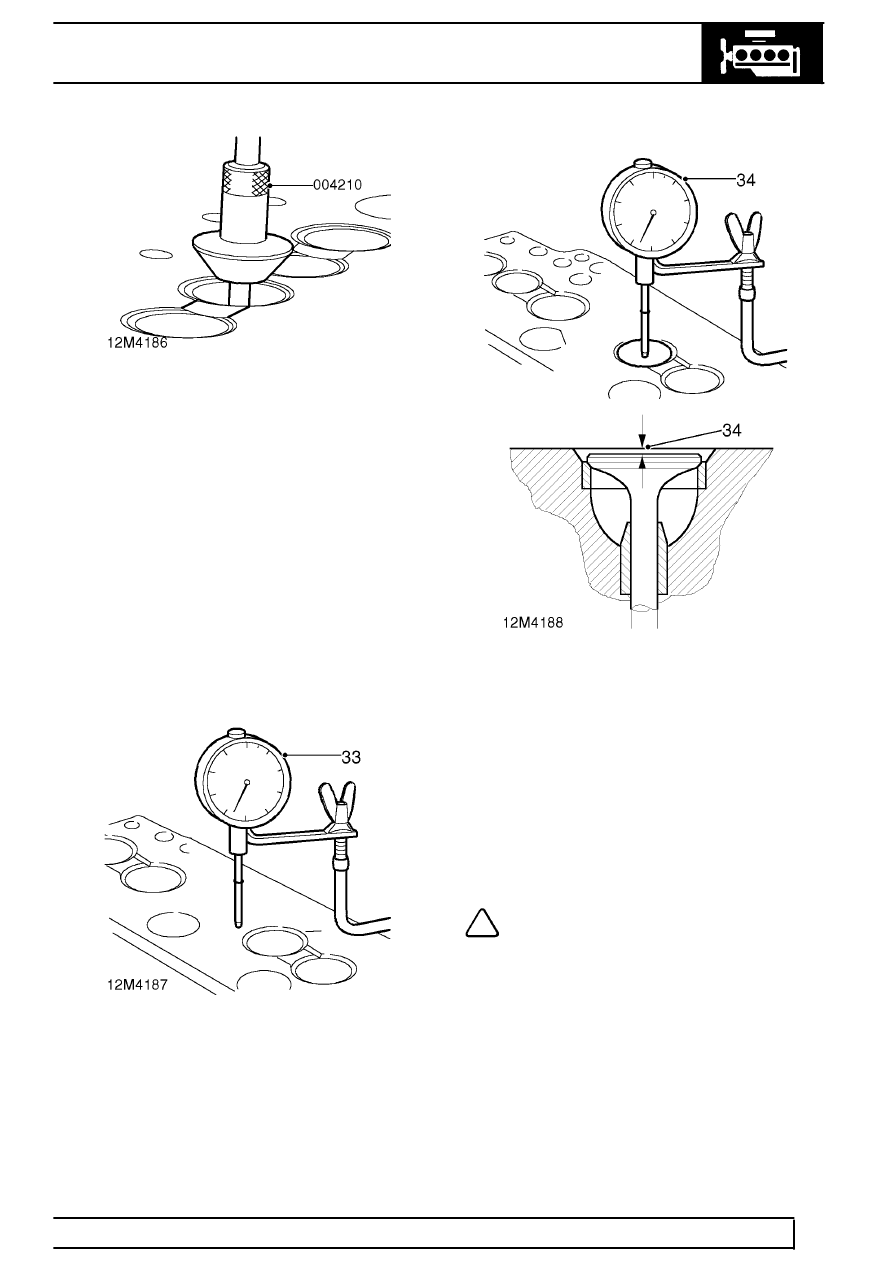

33

REPAIR

28. Dry ream valve guides using BMW tool 004210

and appropriate size reamer from those supplied

with tool.

29. Ream valve guide from combustion chamber

side, rotate tool once only in a downwards

direction; remove all traces of swarf on

completion.

Check valve head stand-down

30.

Original valves: Lap valves to their seats,

remove all traces of grinding paste on

completion.

31.

Replacement valves: Do not lap valves to their

seats.

32. Insert No.1 valve into its guide.

33. Position suitable DTI to cylinder head, pre-load

then zero gauge.

34. Position DTI to centre of valve, measure valve

head stand-down and compare with figures

given:

Inlet = 0.65 to 0.85 mm (0.02 to 0.03 in)

Exhaust = 0.85 to 1.05 mm (0.03 to 0.04 in)

35. Replace any valve having stand-down in excess

of figures given with a valve having an increased

head thickness.

36. Refer to the following to determine thickness of

valve head required ensuring that valves with

correct size stem diameter are obtained.

NOTE: It will be necessary to re-cut valve

seats when fitting valves with increased

head thickness.

Standard valve stem diameter:

Head thickness increase - 0.25 mm (0.01 in)

Identification marks - RO