Range Rover P38

CLUTCH

3

REPAIR

Refit

16. Ensure mating faces are clean.

NOTE: New friction plates are supplied

with splines pre-greased.

17. If refitting existing friction plate, smear splines

with ’Molycote FB180’.

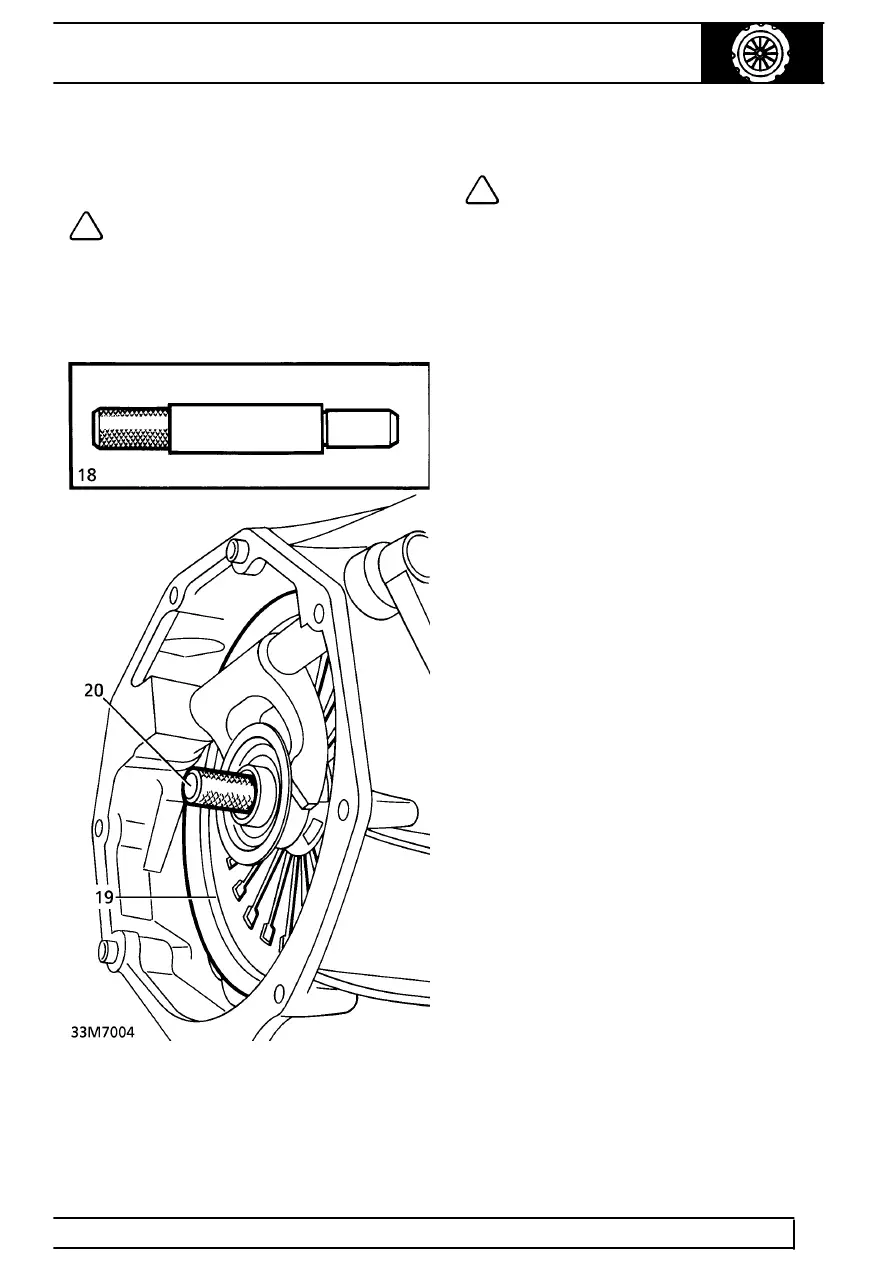

18. Position friction plate on flywheel. Fit

LRT-12-001 to align plate.

19. Position cover. Locate on dowels.

NOTE: If original cover is refitted, align

marks.

20. Secure cover with bolts. Tighten progressively,

in a diagonal sequence to

40 Nm (30 lbf.ft).

Remove LRT-12-001.

21. Position clutch housing onto dowels. Ensure

release fork engages with release bearing.

22. Secure clutch housing with bolts. Tighten to

40 Nm (30 lbf.ft)

23. Position flywheel access cover. Secure with

bolts.

24. Smear release lever push rod socket with

’Molycote FB180’.

25. Position slave cylinder on clutch housing.

Ensure pushrod is engaged with lever. Secure

cylinder with bolts. Tighten to

45 Nm (33 lbf.ft)

26. Secure push rod gaiter to clutch lever.

27. Fit gearbox assembly.

See MANUAL

GEARBOX, Repair.