Leon Mk1

|

|

|

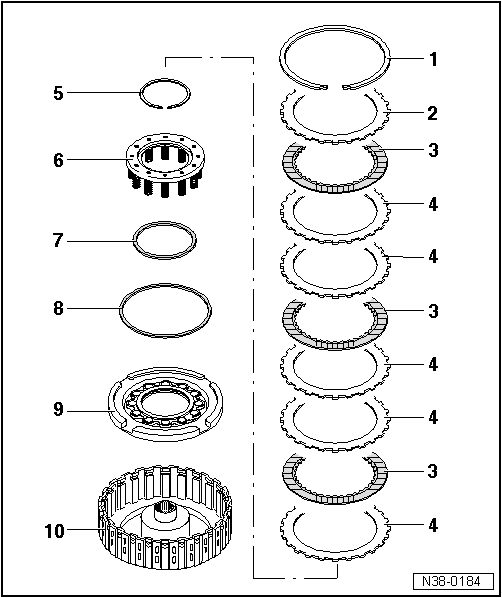

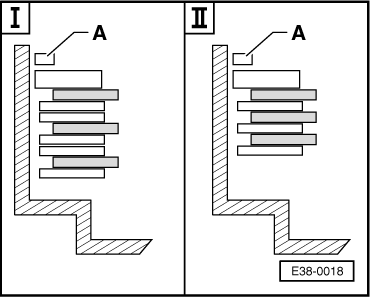

| Take note of the number of discs and their assembly position when dismantling → Fig. |

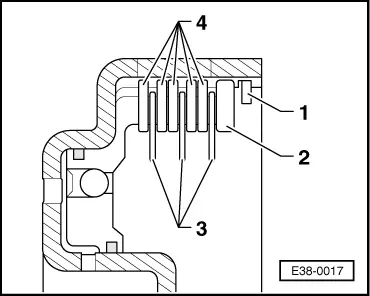

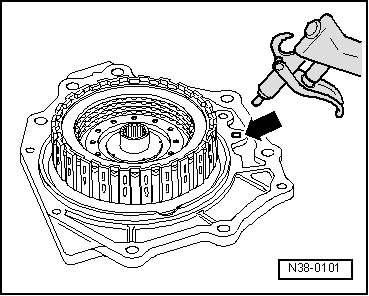

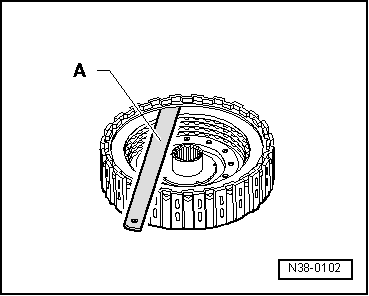

| Checking the clutch action → Fig. |

| 1 - | Safety ring |

| q | Remove by levering with a screwdriver |

| 2 - | Support disc |

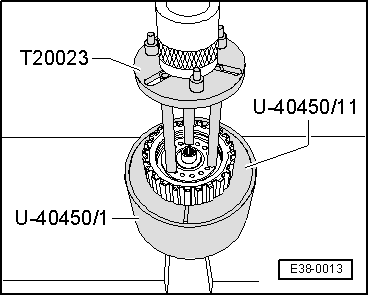

| q | Fitting → Fig. |

| q | Determine thickness → Fig. |

| 3 - | Inner disc |

| q | Fitting → Fig. |

| q | Part number → Chapter |

| 4 - | Outer disc |

| q | Fitting → Fig. |

| q | Part number → Chapter |

| 5 - | Safety ring |

| q | Dismantling and fitting → Fig. |

| 6 - | Spring support plate |

| q | With springs |

| 7 - | Oil seal |

| q | Always renew |

| 8 - | Oil seal |

| q | Always renew |

| 9 - | Piston |

| q | The corresponding gearbox code is assigned to this spare part |

| q | Before fitting, moisten the sealing lips with ATF |

| q | On fitting, turn the piston slightly |

| q | After fitting, it should be possible to rotate the piston in the clutch bell housing |

| 10 - | Clutch bell housing |

|

|

|

|

|

|

|

|

| Component | Dim. | Wear limit |

| Clutch K3 | 1.8 ... 2.2 mm | 2.4 mm |

|