Leon Mk1

|

|

|

|

|

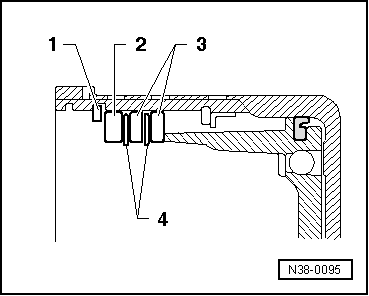

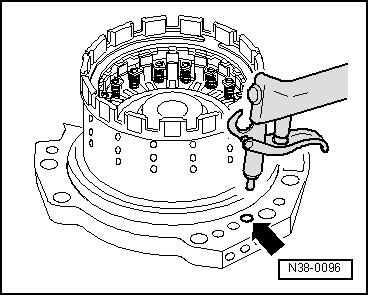

| Checking the clutch action → Fig. |

| 1 - | Safety ring |

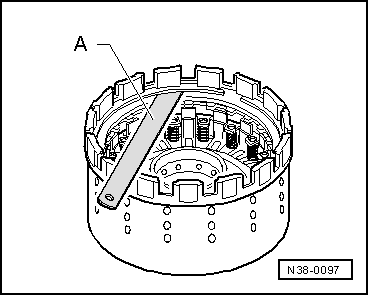

| q | Mark when dismantled and assemble in the same position |

| 2 - | Support disc |

| q | Fitting → Fig. |

| q | Determine thickness → Fig. |

| 3 - | Inner disc |

| q | Fitting → Fig. |

| q | Part number → Chapter |

| 4 - | Outer disc |

| q | Fitting → Fig. |

| q | Part number → Chapter |

| 5 - | Safety ring |

| q | Remove by levering with a screwdriver |

| q | Fitting → Fig. |

| 6 - | Spring support plate |

| q | With springs |

| q | Fitting → Fig. |

| 7 - | Oil seal |

| q | Always renew |

| 8 - | Piston |

| q | Choose the spare part according to the gearbox code |

| q | Fitting → Fig. |

| 9 - | Oil seal |

| q | Always renew |

| q | The sealing lip should be facing the clutch bell housing |

| 10 - | Clutch bell housing |

|

|

|

|

|

|

| Component | Dim. | Wear limit |

| Clutch K2 | 0.5 ... 0.8 mm | 1 mm |

|