Leon Mk1

|

|

|

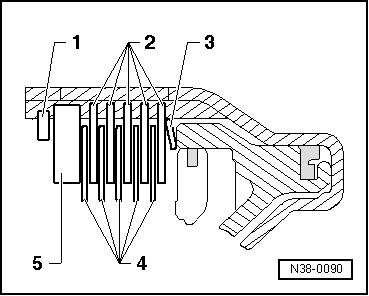

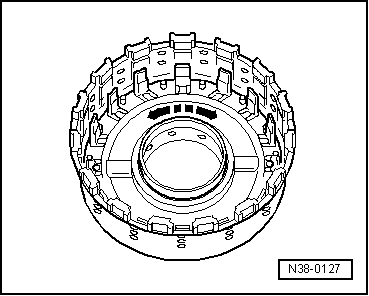

| Checking clutch action → Fig. |

| 1 - | Safety ring |

| q | Remove by levering with a screwdriver |

| 2 - | Support disc |

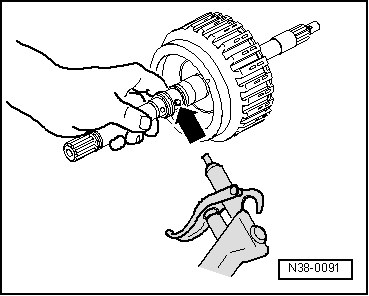

| q | Fitting → Fig. |

| q | Determine thickness → Fig. |

| 3 - | Inner disc |

| q | Fitting → Fig. |

| q | Part number → Chapter, Code letters, group numbers, ratios, equipment |

| 4 - | Outer disc |

| q | Fitting → Fig. |

| q | Part number → Chapter, Code letters, group numbers, ratios, equipment |

| 5 - | Plate spring |

| q | Fitting → Fig. |

| q | The convex side (small diameter) should face the clutch bell housing |

| 6 - | Safety ring |

| q | Dismantling and fitting → Fig. |

| 7 - | Oil seal |

| q | Always renew |

| 8 - | Piston cover |

| q | Before fitting, soak in oil seals with ATF |

| 9 - | Spring |

| q | Place between the piston and the piston cover |

| 10 - | Oil seal |

| q | Always renew |

| q | The sealing lip should be facing the clutch bell housing |

| 11 - | Oil seal |

| q | Always renew |

| 12 - | Piston |

| q | The corresponding gearbox code is assigned to this spare part |

| q | Before fitting, moisten the sealing lips with ATF |

| q | On fitting, turn the piston slightly |

| q | After fitting, it should be possible to rotate the piston in the clutch bell housing |

| 13 - | Clutch bell housing with turbine shaft |

| 14 - | Piston ring |

| q | Checking the correct adjustment |

| q | Do not over-expand |

|

|

|

|

| Component | Dim. | Wear limit |

| Clutch K1 | 0.45 ... 0.85 mm | 1.05 mm |

|

|

|

|

|