Leon Mk1

| Differential: dismantling and assembling |

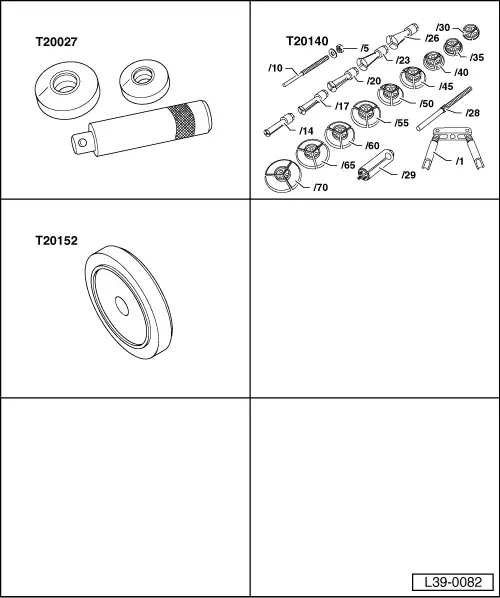

| Special tools and workshop equipment required |

| t | -T20022- Kit |

| t | Pressure tool -T20047- |

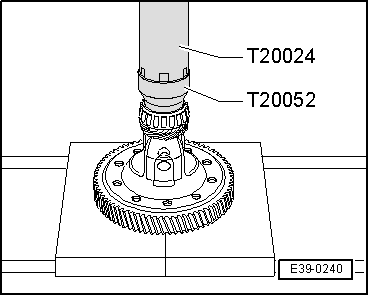

| t | Plunger -T20052- |

| t | -U-40100- Kit |

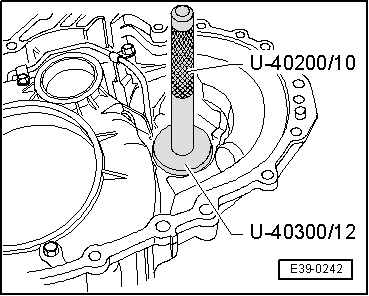

| t | -U-40200 A- Kit |

| t | -U-40300- Kit |

| t | Plunger -T20027- |

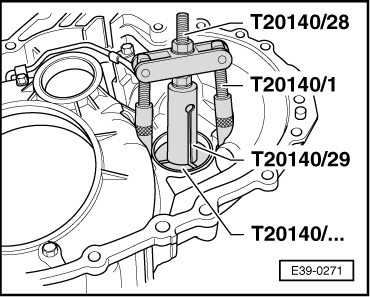

| t | -T20140- Kit |

| t | Plunger -T20152- |

Note!

Note!| To avoid premature wear and noise, the roller bearings on a shaft should be replaced at the same time |

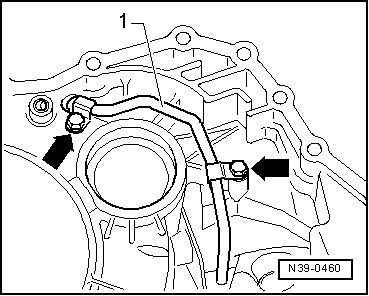

| 1 - | Torque converter casing |

| q | Dismantling and fitting → Chapter |

| q | Oil pipe: removing and installing → Fig. |

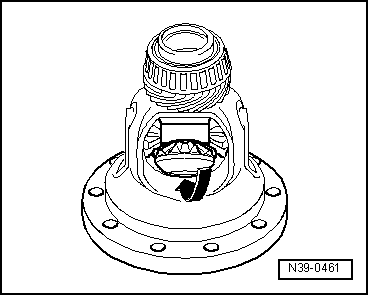

| 2 - | Thrust washer |

| q | For satellite |

| 3 - | Satellite |

| q | Fitting → Fig. |

| 4 - | Thrust washer |

| q | For the planet gear |

| 5 - | Planet gear |

| q | Fitting → Fig. |

| 6 - | Threaded component |

| 7 - | Support sleeve |

| q | To hold the satellite shaft |

| q | Extract and replace with a punch |

| 8 - | Satellite shaft |

| q | Extract by striking with a punch |

| q | On fitting, do not damage the thrust washers |

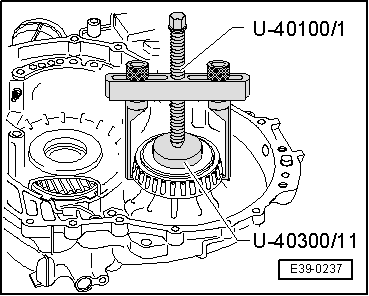

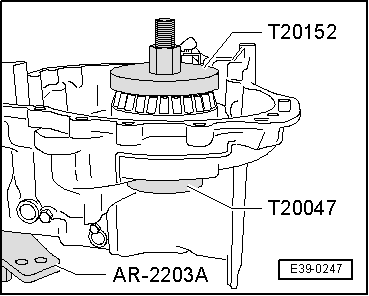

| 9 - | Outer ring of roller bearing |

| q | Remove → Fig. |

| q | Fit into the differential housing → Fig. |

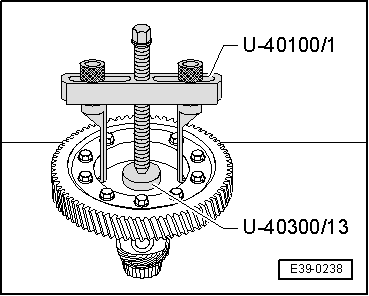

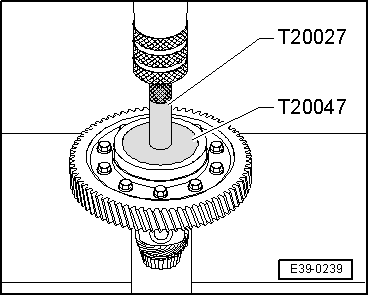

| 10 - | Inner ring of roller bearing |

| q | Remove → Fig. |

| q | Fit into the gearbox casing → Fig. |

| 11 - | Gearbox casing |

| q | Differential: removing and installing → Chapter |

| 12 - | Bolt |

| q | 80 Nm |

| 13 - | Differential casing |

| 14 - | Crown |

| q | Number of teeth → Chapter, Code letters, group numbers, ratios, equipment |

| 15 - | Speedometer drive sprocket |

| q | Fit the projections of the drive sprocket into the groove in the differential casing, flat side facing outwards |

| 16 - | Inner ring of roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

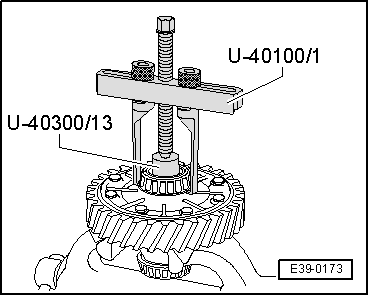

| 17 - | Outer ring of roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 18 - | Shim |

| q | Determine thickness → Chapter |

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

|

|

|

|

|

|