Leon Mk1

| Engine shaft: dismantling and assembling |

| Special tools and workshop equipment required |

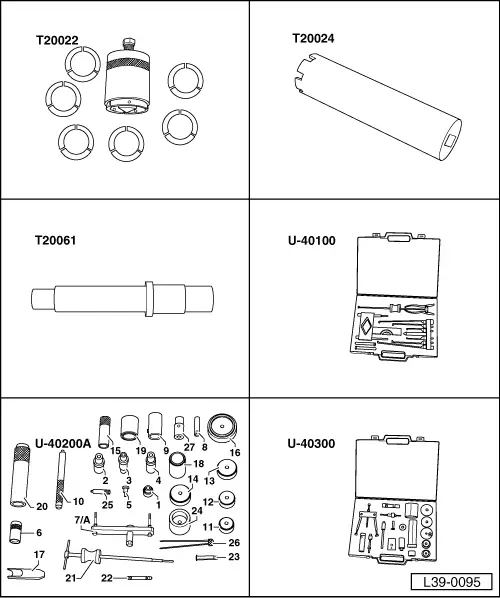

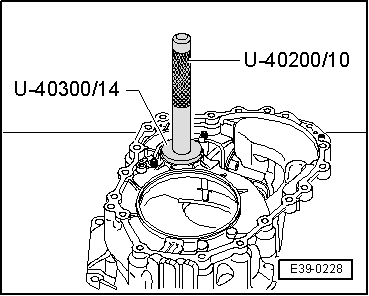

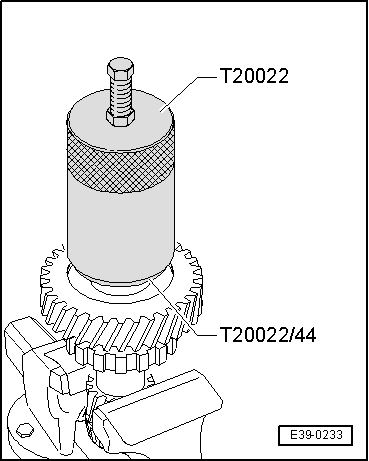

| t | Kit -T20022- |

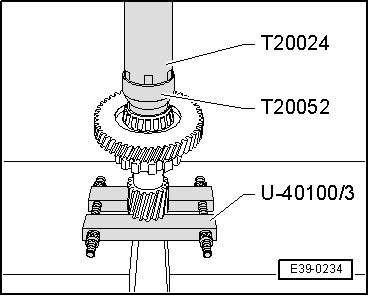

| t | Rotation tool -T20024- |

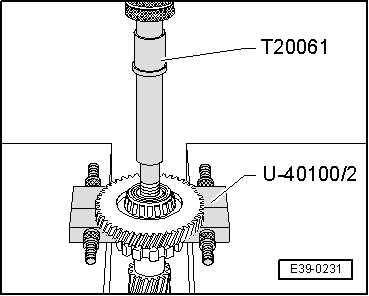

| t | Plunger -T20061- |

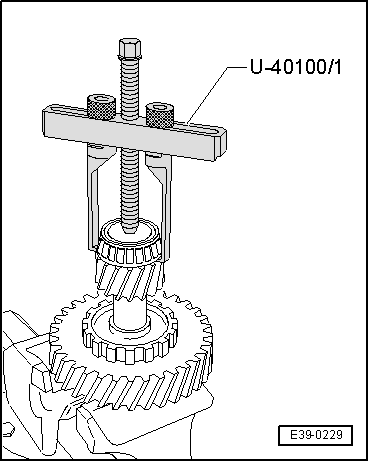

| t | Kit -U-40100- |

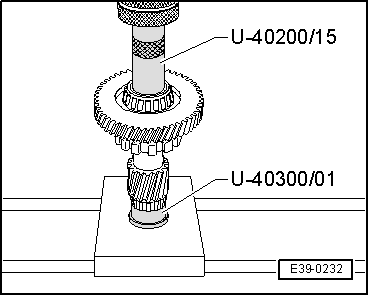

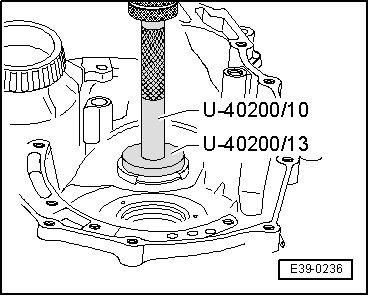

| t | Kit -U-40200A- |

| t | Kit -U-40300- |

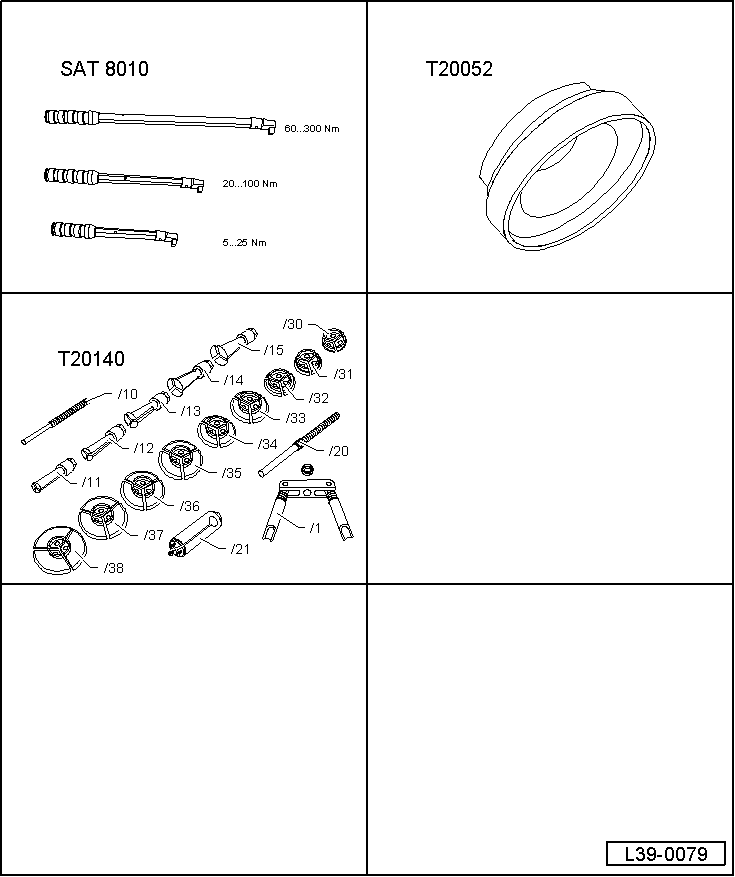

| t | Torque spanners -SAT 8010- |

| t | Plunger -T20052- |

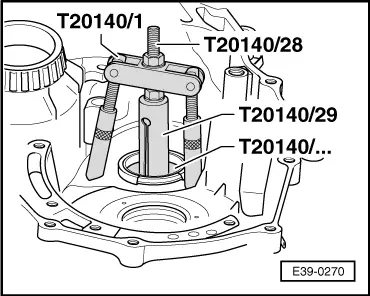

| t | Kit -T20140- |

Note!

Note!| t | To remove the engine shaft, first remove the planet gear until the large planet, once the torque converter casing has been dismantled → Chapter, Planet gears: dismantling and assembling |

| t | To avoid premature wear and noise, the roller bearings on a shaft should be replaced at the same time |

| 1 - | Torque converter casing |

| 2 - | Shim |

| q | Determine thickness → Chapter, crown/pinion sprocket: adjusting |

| 3 - | Outer ring of roller bearing |

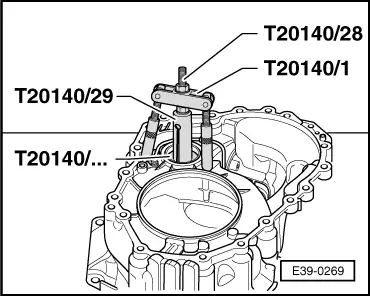

| q | Release → Fig. |

| q | Fit → Fig. |

| 4 - | Inner ring of roller bearing |

| q | Release → Fig. |

| q | Fit → Fig. |

| 5 - | Engine shaft |

| q | Number of teeth → Chapter, Code letters, group numbers, ratios, equipment |

| q | Adjust → Chapter |

| 6 - | Parking lock sprocket |

| 7 - | Driven sprocket |

| q | Number of teeth → Chapter, Code letters, group numbers, ratios, equipment |

| q | Release → Fig. |

| q | Fit → Fig. |

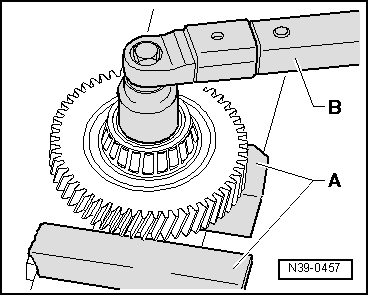

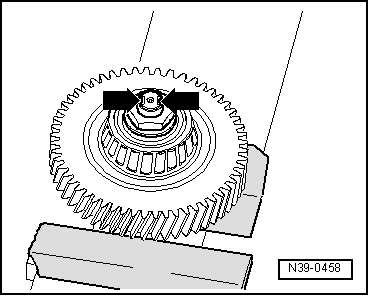

| 8 - | Nut |

| q | 145 Nm |

| q | Always renew |

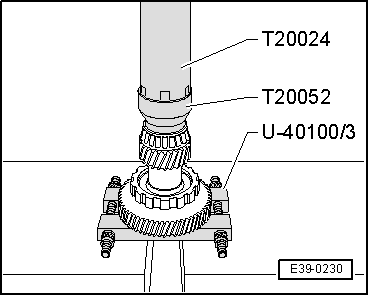

| q | Loosen and tighten → Fig. |

| q | Secure → Fig. |

| 9 - | Inner ring of roller bearing |

| q | Release → Fig. |

| q | Fit → Fig. |

| 10 - | Outer ring of roller bearing |

| q | Release → Fig. |

| q | Fit → Fig. |

| 11 - | Gearbox casing |

|

|

|

|

Note!

Note!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|