Leon Mk1

|

|

|

|

|

| Assembly Chart |

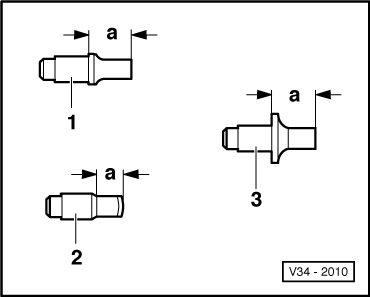

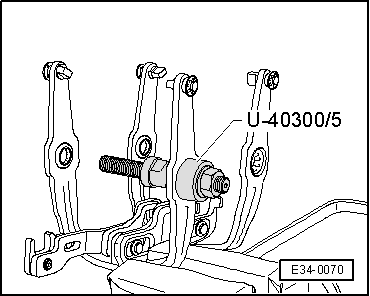

| 1 - | Gear switch anchor bolt |

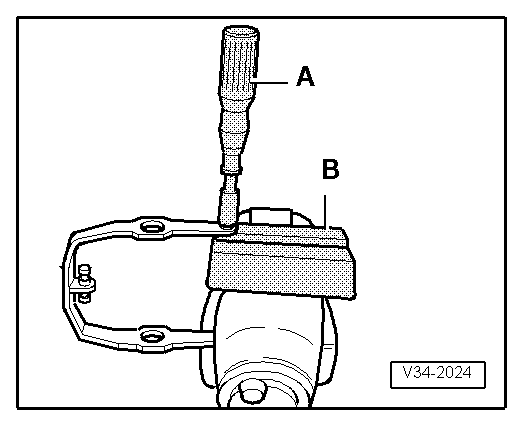

| q | Identification → Fig. |

| q | After assembling the safety washer, the blocks must be able to move slightly. |

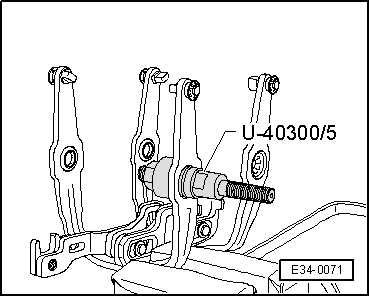

| 2 - | Pressure washer |

| q | Separate the pressure washer by levering carefully with a screwdriver. |

| q | Assembly → Fig. |

| q | Always replace |

| 3 - | 5th gear fork |

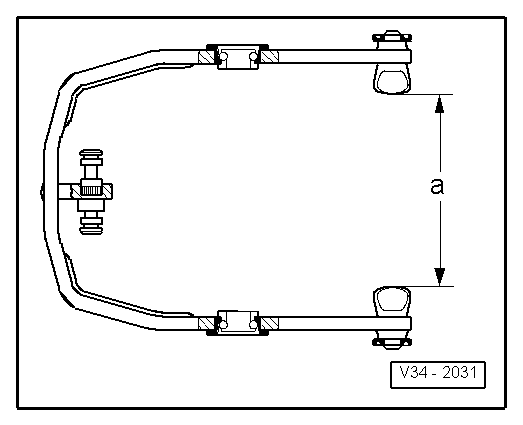

| q | Adjust → Fig. |

| 4 - | 5th gear connection hub |

| 5 - | Bolt, 25 Nm |

| 6 - | 5th gear connection guide |

| 7 - | Safety ring |

| 8 - | Washer |

| 9 - | Connection guide for 3rd and 4th gears |

| 10 - | Connection guide for 1st and 2nd gears |

| 11 - | Connection guide for reverse gear |

| 12 - | Fork for 3rd and 4th gears |

| q | With switch anchor bolt for gears → Fig. |

| 13 - | Switch anchor bolt for gears |

| q | Identification → Fig. |

| q | After the assembly of the safety wa-sher, the blocks must be able to move slightly |

| 14 - | Ball bearing |

| 15 - | Inner ring of the ball bearing |

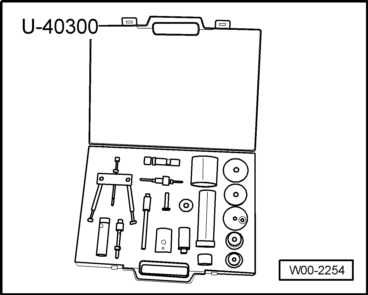

| q | Dismount → Fig. |

| q | Fitting → Fig. |

| 16 - | 1st/2nd gear fork |

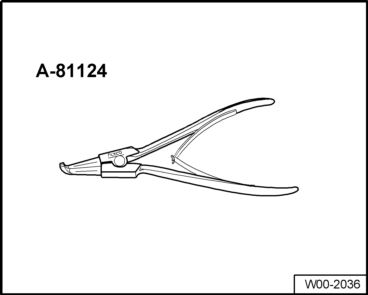

| q | With blocks for the gearbox forks → Fig. |

| 17 - | Reverse gear switch anchor bolt |

| q | Identification → Fig. |

| q | After the assembly of the safety washer, the blocks must be able to move slightly. |

| 18 - | Safety ring |

| 19 - | Support for reverse gear fork |

| 20 - | Reverse gear fork |

| 21 - | Spring |

| 22 - | Sliding block |

|

|

Note!

Note!

|

|

Note!

Note!

|

|

|

|

| Gap height -A- (mm) | |

| 1st and 2nd gear fork | 87.2 … 87.9 |

| 3rd and 4th gear fork | 96.0 … 96.7 |

|