Leon Mk1

|

|

|

|

|

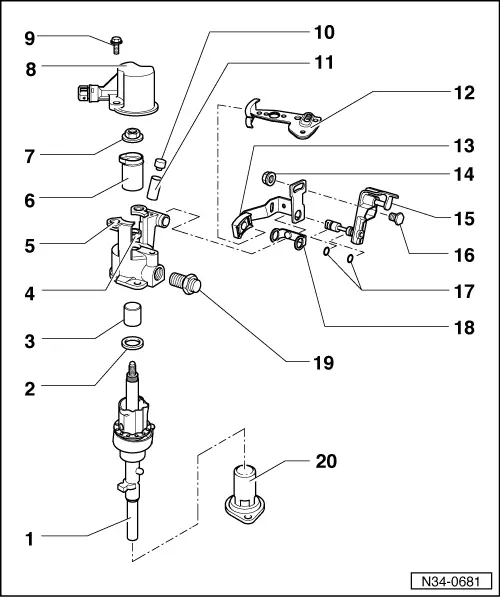

| Assembly chart |

| 1 - | Selection axle |

| 2 - | Stop ring |

| 3 - | Ball bearning sleeve |

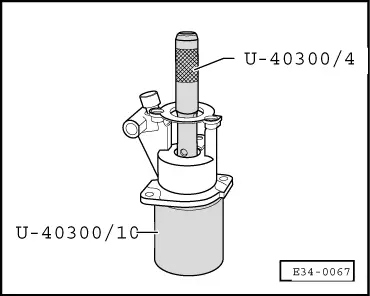

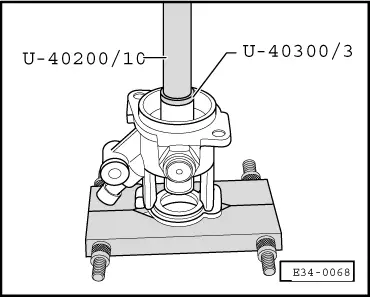

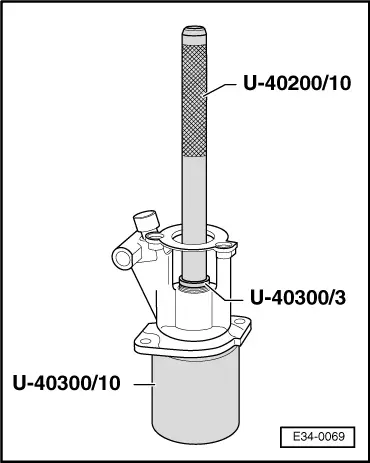

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| 4 - | Seal ring |

| q | Remove by levering with a screwdriver. |

| q | Assemble → Fig. |

| 5 - | Connection top |

| 6 - | Crown |

| q | The bead faces towards the switch for the reverse gear light. |

| q | Apply a fine layer of MoS2 grease onto the bead. |

| 7 - | Hexagonal nut, 25 Nm |

| q | Self-blocking |

| q | Always replace |

| 8 - | Support |

| q | For the reverse gear light switch. |

| 9 - | Bolt |

| 10 - | Top |

| q | Vent top for the gearbox |

| 11 - | Sleeve |

| q | Fit it to the end, if it comes as an individual component |

| 12 - | Selection lever |

| q | Position for assembly: The cog of the gear stick only fits in with the cog of the gear stick in one position. |

| q | It can be changed with the gear stick mounted in the vehicle. |

| q | Position for assembly → Chapter |

| 13 - | Return lever |

| 14 - | Nut, 15 Nm |

| 15 - | Drag part |

| q | With the axle for housing the return lever. |

| q | Position for assembly → Chapter |

| 16 - | Bolt |

| q | Insert it into the drag part. |

| 17 - | O-ring seals |

| q | Assemble them on the axle of the drag parts. |

| 18 - | Separating part |

| q | Insert it on the return lever. |

| 19 - | Bolt for blocking, 40 Nm |

| 20 - | Seal top |

|

|

|

|