Leon Mk1

| Gearbox casing and clutch casing: repair |

| Assembly chart |

| 1 - | Gearbox casing |

| q | In the event of replacement, see adjustment chart → Chapter |

| 2 - | Secondary shaft needle bearing |

| q | For secondary shaft |

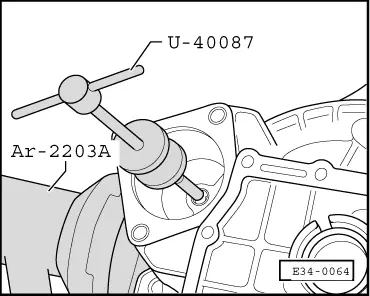

| q | Dismount → Fig. |

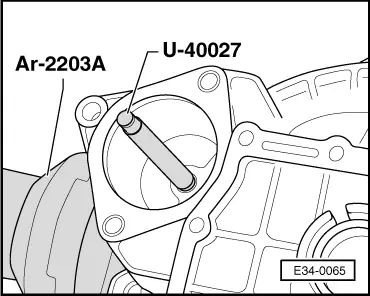

| q | Assemble and fix into place → Fig. |

| 3 - | Lid for control of oil level. 25 Nm |

| q | Without magnet |

| 4 - | Primary shaft needle bearing |

| q | In the event of replacement, see adjustment chart → Anchor |

| 5 - | Outer track, tapered roller bearing for main shaft |

| q | Dismount and assemble → Chapter |

| q | In the event of replacement, see adjustment chart → Chapter |

| 6 - | Outer track, tapered roller bearing for secondary shaft |

| q | Dismount and assemble → Chapter |

| q | In the event of replacement, see adjustment chart → Chapter |

| 7 - | Adjustment washer for secondary shaft |

| q | In the event of replacement, see adjustment chart → Anchor |

| 8 - | Outer track, tapered roller bearing for main shaft |

| q | Dismount and assemble → Chapter |

| q | In the event of replacement, see adjustment chart → Chapter |

| 9 - | Axial/radial needle bearing for reverse gear axle |

| q | Dismount and assemble → Chapter |

| 10 - | Centring bushes |

| q | 2 units |

| 11 - | Bush-bearing for the start motor |

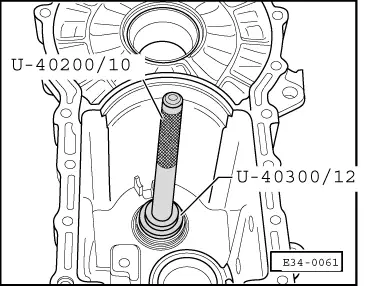

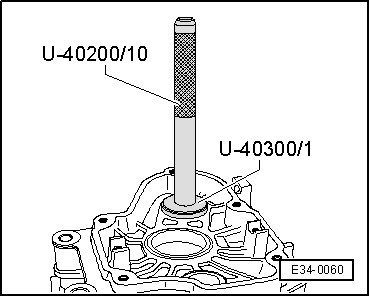

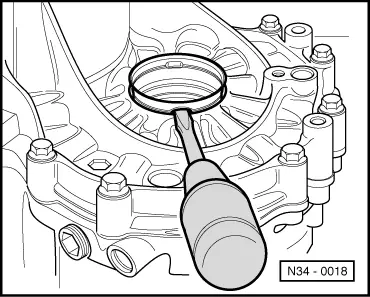

| q | Remove → Fig. |

| q | Assemble → Fig. |

| q | It may be replaced with the gearbox mounted. |

| 12 - | Clutch casing |

| q | In the event of replacement, see adjustment chart → Chapter |

| 13 - | Guide sleeve |

| q | With retainer for main shaft and vulcanised O-ring seal |

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| q | In order to replace the retainer for the main shaft it is necessary that the guide sleeve be dismounted. |

| q | Replace the guide sleeve if the O-ring seal is damaged. |

| 14 - | Bolt for attaching the guide sleeve. 20 Nm |

| q | Self-blocking |

| q | Always replace |

| q | Tightening torque: 20 Nm |

| 15 - | Retainer for right coupling flange |

| q | Replacement with the gearbox mounted in the vehicle → Chapter |

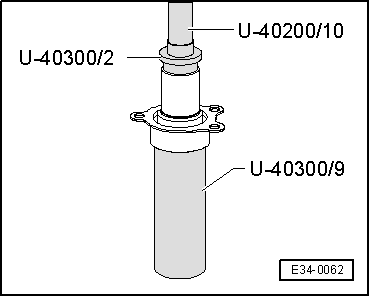

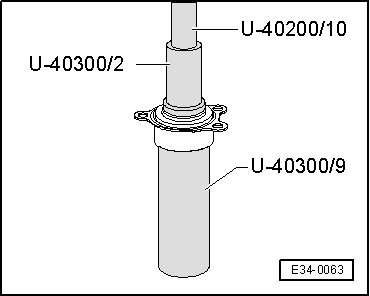

| 16 - | Plate sleeve |

| q | For coupling flange retainer → Item |

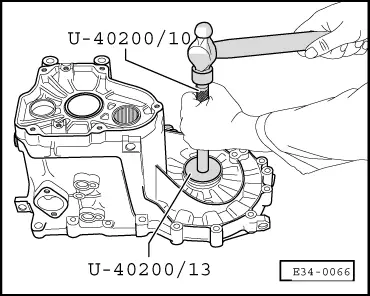

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| 17 - | Shaft for operating speedometer 30 Nm |

| 18 - | Top for emptying oil. 25 Nm |

| q | Without a magnet |

| 19 - | Outer track for the tapered roller bearing in the differential |

| q | Dismount and assemble → Fig. |

| q | In the event of replacement, adjust the differential → Chapter |

| 20 - | Magnet |

| q | It is held between the casings for the gearbox and the clutch |

| 21 - | Outer track for the tapered roller bearing in the differential |

| q | Dismount and assemble → Fig. |

| q | In the event of replacement, adjust the differential → Chapter |

| 22 - | Adjustment washer for differential |

| q | Finding the thickness → |

| 23 - | Retainer for left flange |

| q | Replacement with the gearbox mounted in the vehicle → Chapter |

| Special tools and workshop equipment required |

| t | Gearbox repairs case -U-40200- |

| t | Gearbox repairs case -U-40300- |

| t | Taps for Ø 11 and Ø 14 with plunger -U-40087- |

| t | Tool for assembling starter sleeve -U-40027- |

| t | Support column for gearbox-differential -AR-2203A- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|