Leon Mk1

| Gearbox housing and clutch housing: repairing |

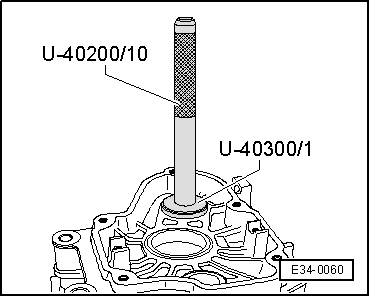

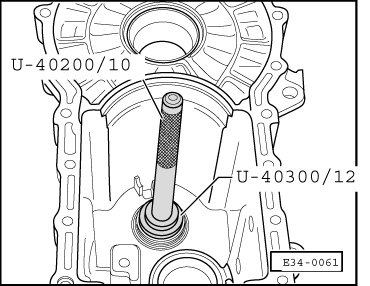

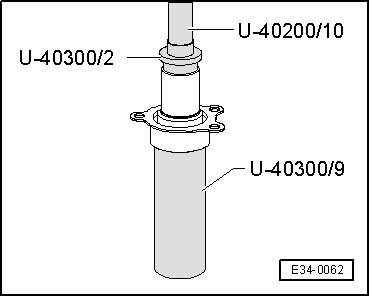

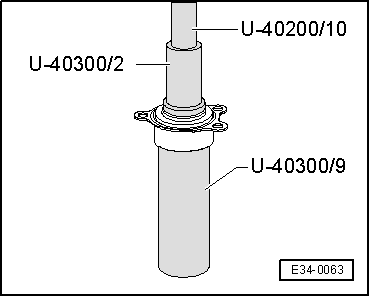

| Special tools and workshop equipment required |

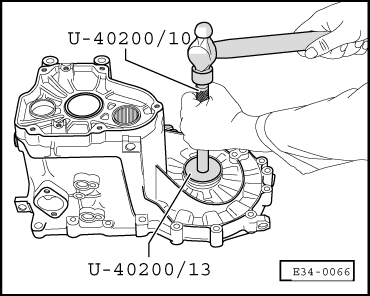

| t | Gearbox repair set -U-40200- |

| t | Gearbox repair set -U-40300- |

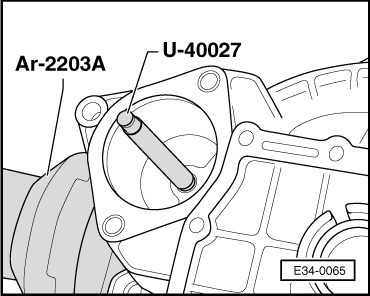

| t | Tool for fitting starter motor bush -U-40027- |

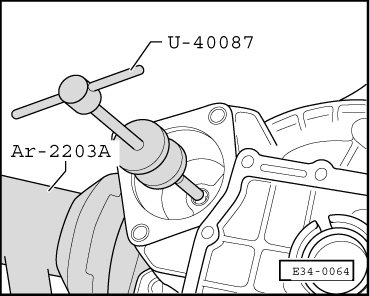

| t | Taps for Ø 11 and Ø 14 with hammer -U-40087- |

| t | Gearbox-differential support column -AR-2203A- |

| 1 - | Gearbox casing |

| q | If replaced, refer to Adjustment chart → Chapter |

| 2 - | Needle roller bearing |

| q | For layshaft |

| q | Remove → Fig. |

| q | Installing and securing → Fig. |

| 3 - | Oil filler cap |

| q | 25 Nm |

| q | Without magnet |

| 4 - | Outer track, roller bearing |

| q | For layshaft |

| q | Removing and fitting → Item |

| q | If replaced, adjust layshaft → Chapter |

| 5 - | Shim |

| q | For layshaft |

| q | If replaced, refer to Adjustment chart → Chapter |

| 6 - | Shim |

| q | For input shaft |

| q | If replaced, refer to Adjustment chart → Chapter |

| 7 - | Outer track, roller bearing |

| q | For input shaft |

| q | Removing and fitting → Item |

| q | If replaced, adjust input shaft → Chapter |

| 8 - | Outer track, roller bearing |

| q | For input shaft |

| q | Removing and fitting → Item |

| q | If replaced, adjust input shaft → Chapter |

| 9 - | Axial/radial needle bearing |

| q | For the reverse gear/shaft |

| q | Removing and fitting → Item |

| 10 - | Dowel pegs |

| 11 - | Starter motor bush |

| q | Remove → Fig. |

| q | Fit → Fig. |

| q | Can be replaced with the gearbox in place |

| 12 - | Clutch housing |

| q | If replaced, refer to Adjustment chart → Chapter |

| 13 - | Guide bush |

| q | With protector ring for input shaft and vulcanised O-ring |

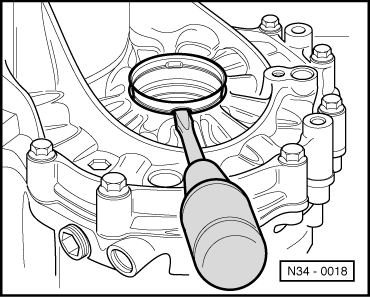

| q | Unclip the protector ring → Fig. |

| q | Fitting the outer ring → Fig. |

| q | To renew the input shaft protector ring the guide bush must be removed |

| q | Renew the guide bush and O-ring together if the latter is damaged |

| 14 - | Bolt |

| q | 20 Nm |

| q | Self-locking |

| q | Always renew |

| 15 - | Oil seal |

| q | Replacement with gearbox in vehicle → Chapter, Articulation flange oilseals: removing and installing |

| 16 - | Bush |

| q | For articulation flange oilseal → Item |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 17 - | Speedometer mechanism shaft |

| q | 30 Nm |

| 18 - | Oil draining cap |

| q | 25 Nm |

| q | Without magnet |

| 19 - | Outer track, roller bearing |

| q | For the differential |

| q | Removing and fitting → Chapter, Differential: dismantling and assembling |

| q | If replaced, adjust differential → Chapter |

| 20 - | Magnet |

| q | Supported between gearbox and clutch housings |

| 21 - | Outer track, roller bearing |

| q | For the differential |

| q | Removing and fitting → Chapter, Differential: dismantling and assembling |

| q | If replaced, adjust differentiall → Chapter |

| 22 - | Shim |

| q | For differential |

| q | Determine thickness → Anchor |

| 23 - | Oil seal |

| q | For articulation flange |

| q | Replacement with gearbox in vehicle → Chapter, Articulation flange oilseals: removing and installing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|