Leon Mk1

| Layshaft: adjustment |

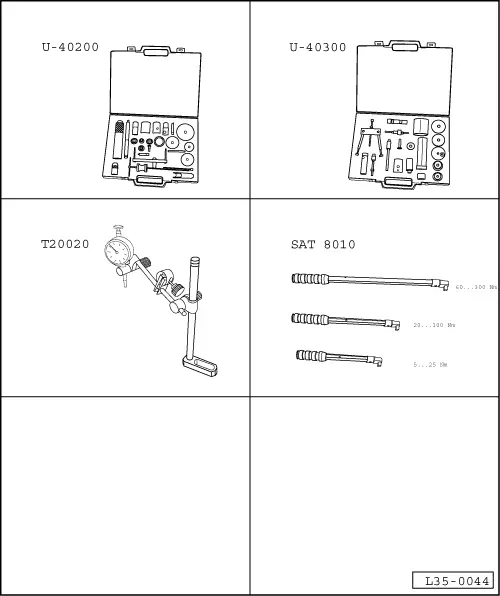

| Special tools and workshop equipment required |

| t | Gearbox repair set -U-40200- |

| t | Gearbox repair set -U-40300- |

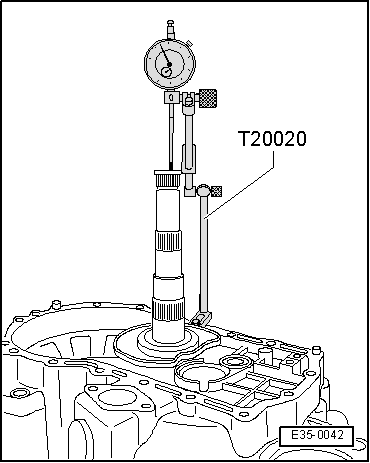

| t | Universal dial gauge bracket -T20020- |

| t | Torque spanner -SAT 8010- |

|

|

|

Note!

Note!

|

|

| Washer fitted | 0.65 mm |

| + Average value | 0.30 mm |

| + Pressure (const. value) | 0.20 mm |

| Shim thickness needed | 1.15 mm |

|

| Thickness (mm) | Spare no. |

| 0.65 0.70 | 020 311 391 P 020 311 391 Q |

| 0.75 0.80 0.85 | 020 311 391 020 311 391 A 020 311 391 B |

| 0.90 0.95 1.00 | 020 311 391 C 020 311 391 D 020 311 391 E |

| 1.05 1.10 1.15 | 020 311 391 F 020 311 391 G 020 311 391 H |

| 1.20 1.25 1.30 | 020 311 391 J 020 311 391 K 020 311 391 L |

| 1.35 1.40 | 020 311 391 M 020 311 391 N |

|

|

|