| –

| Should the thickness of the adjustment washer needed be thicker than the thicknesses that appear in the Table, two adjustment washers may be fitted, the thicknesses for which when added together, correspond to the reading required. |

| –

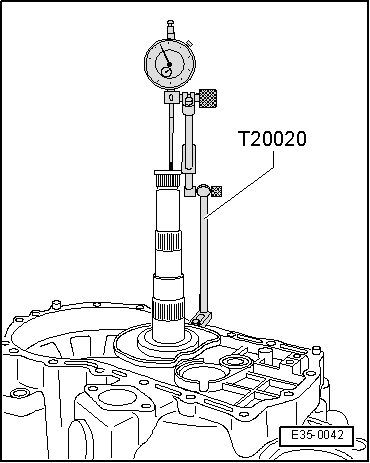

| Once the adjustment washer needed has been determined, remove the comparator. |

| –

| Separate the secondary shaft. |

| –

| Dismount the outer track for the tapered roller bearing by carrying out the following steps: |

| –

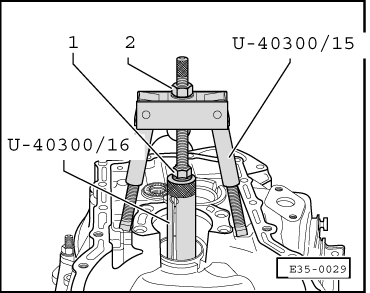

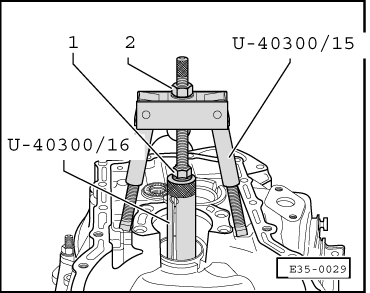

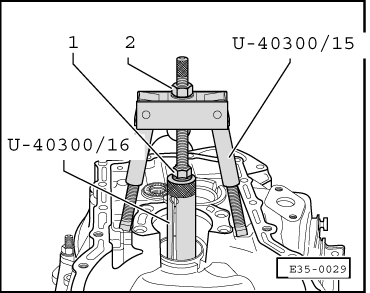

| Assemble the grips -U-40300/17- on the tool -U-40300/16- using its attachment bolts. |

| –

| Place the set of tools on the lower part of the outer track of the tapered roller bearing. Expand the tool -U-40300/16- by tightening the bolt -1-. |

| –

| Place the extractor tool -U-40300/15- on the clutch casing and tighten the axle of the extractor into the tool-U-40300/16-. |

| –

| Turn the nut -2- until extracting the outer track of the tapered roller bearing. |

| –

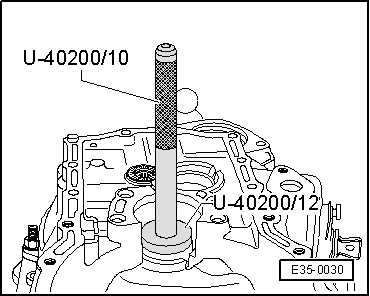

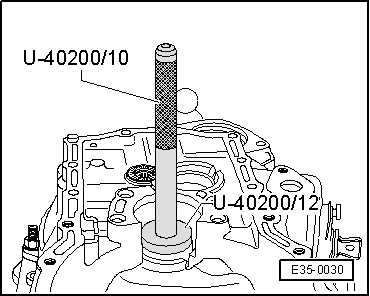

| Remove the washer that is 0.65 mm thick. |

|

|

|

Note!

Note!