Leon Mk1

|

|

|

Note

Note

|

|

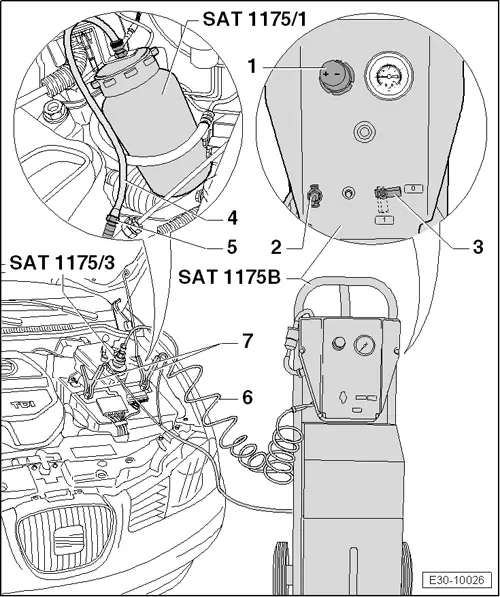

| – | Connect lines -7- of brake bleeder -SAT 1175B- to vehicle battery (12V); observe polarity (red + black -). |

| – | Unscrew the plug of the brake fluid tank. |

| – | Connect universal cover -SAT 1175/3- to brake fluid tank and fasten. |

Note

Note| t | Check whether probe of universal covers -SAT 1175/3-is below brake fluid level. |

| t | This ensures that the brake fluid is returned to the proper level after completing the operation. If necessary, add brake fluid after completing the operation. |

| – | Remove hose from bracket at rear of brake bleeder -SAT 1175B- and connect hose -6- to universal cover -SAT 1175/3-. |

| – | Move selection switch -3- to pressure position “1” and switch -2- to “ON”. The pump runs for approx. 15 seconds until the determined pressure is reached. If the pump runs for a longer period of time, check for leakage. |

| – | Select a pressure of “2 bars” with controller -1-. |

Note

Note| The pressure can only be controlled if the unit is operation. |

| – | Remove protective cap from slave cylinder → Item. |

| – | Install bleeder hose -4- on collection bottle -SAT 1175B/1-. |

| – | Connect bleeder hose -4- to bleed valve -5-. |

| – | Open bleed valve -5- and bleed system: |

| – | Allow approx. 100 cm3 of brake fluid to run out. |

| – | Close the air bleeding valve. |

| – | Apply pedal 10 to 15 times and release quickly. |

| – | Open bleed valve -5-. |

| – | Allow additional 50 cm3 of brake fluid to run out until the brake fluid exiting is bubble-free. |

| – | Close the air bleeding valve. |

| – | After finishing air bleeding, the clutch pedal must be activated several times. |

| – | After completion of bleeding, move switch -2- to “OFF” and turn selection switch to “0”. |

Note

Note| To relieve pressure the machine must be “switched off”, the switch turned to “OFF” and the pressure relieved by turning selection switch to “0”. |

| – | Wait approx. 30 seconds so that the remaining brake fluid can run back restoring the correct fluid level in the reservoir. |

| – | Remove hose -6- and universal cover -SAT 1175/3-. Check whether fluid level is okay and install original cap. Use rag to prevent damaging paint. |

Note

Note| Ensure that the brake fluid does not get on the bodywork or any other element. |

WARNING

WARNING