Leon Mk1

|

|

|

|

|

Note!

Note!| t | Replace any clutch plates and pressure plates with damaged or loose rivets. |

| t | If replaced fit clutch and pressure plate according to the Parts Catalogue. |

| 1 - | Engine flywheel |

| q | Check that the centring pins are correctly seated |

| q | The contact surfaces with the clutch plate must be free from grease and without grooves |

| q | Removing and fitting the flywheel → Rep. Gr.13 |

| 2 - | Clutch plate |

| q | Diameter ⇒ page 00-3, Code letters, group numbers, ratios, filling quantities |

| q | If replaced fit plate and pressure plate according to the Parts Catalogue |

| q | Lightly lubricate the splines |

| q | Assembly position: The spring cage should be facing the clutch press |

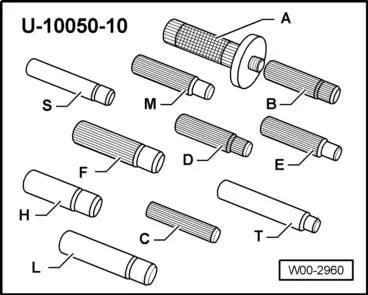

| q | Centring the clutch plate → Fig. |

Note!

Note!| Clean the input shaft and clutch plate splines. Elimimate rust from used clutch plates. Apply a very thin layer of -G 000 100- grease to the input shaft splines. Move the clutch plate backwards and forwards on the input shaft until it slides freely. Eliminate excess grease. |

| 3 - | Clutch press |

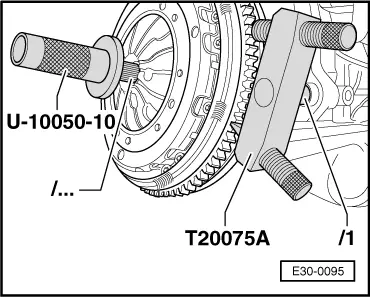

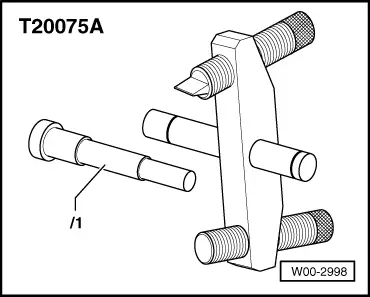

| q | Removing and installing → Fig. |

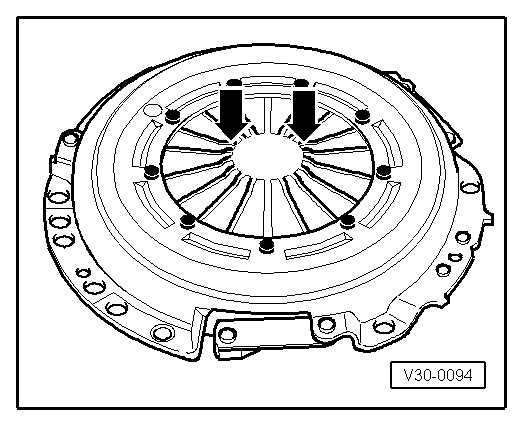

| q | Check the ends of the diaphragm → Fig. |

Note!

Note!| The clutch presses are greased and protected from corrosion. Only clean the contact surface with the clutch plate of any trace of grease or oil, otherwise the life of the clutch will be reduced. |

| 4 - | 20 Nm |

| q | Loosen and tighten diagonally several times |

|

|