Leon Mk1

| Differential: adjustment |

| Special tools and workshop equipment required |

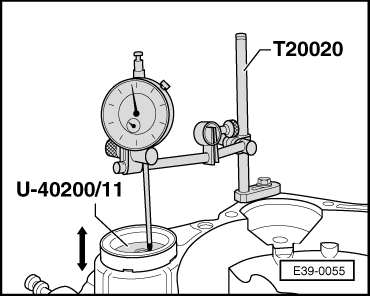

| t | Universal dial gauge bracket -T20020- |

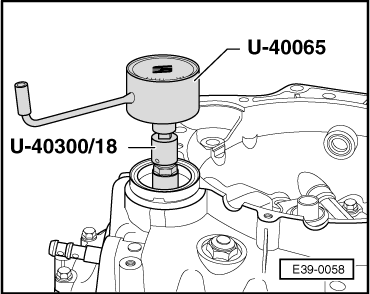

| t | Turn torqe checking tool -U-40065- |

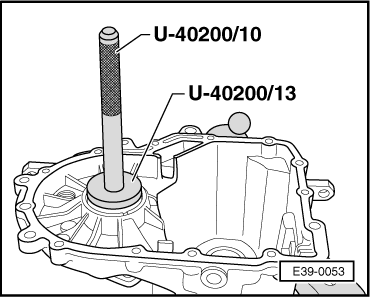

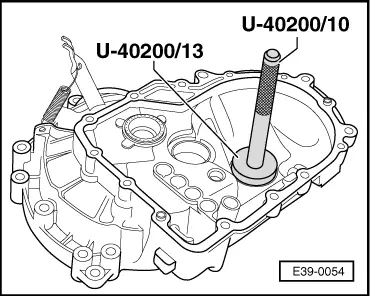

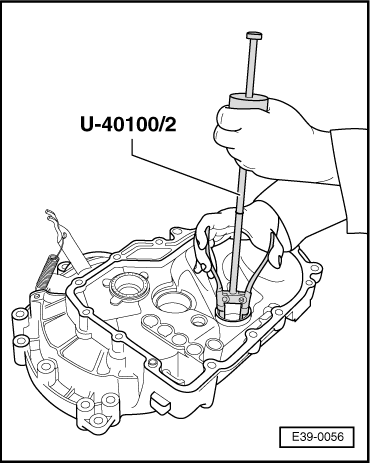

| t | Gearbox extractor set -U-40100- |

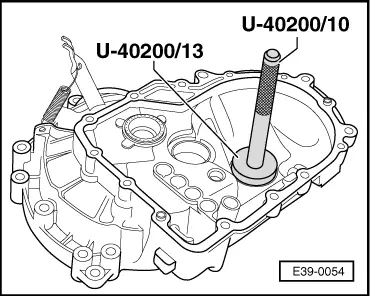

| t | Gearbox repair set -U-40200- |

| t | Gearbox repair set -U-40300- |

|

Note!

Note!

|

|

|

|

Note!

Note!

|

|

| Average value | 1.50 mm |

| + Pressure (const. value) | 0,30 mm |

| S2 shim thickness | 1.80 mm |

|

| Thickness (mm) | Spare no. |

| 1.00 1.40 1.45 | 084 409 383 AE 084 409 383 AF 084 409 383 AG |

| 1.50 1.55 1.60 | 084 409 383 AH 084 409 383 AJ 084 409 383 AK |

| 1.65 1.70 1.75 | 084 409 383 AL 084 409 383 AM 084 409 383 AN |

| 1.80 1.85 1.90 | 084 409 383 AP 084 409 383 AQ 084 409 383 AR |

| 1.95 2.00 2.05 | 084 409 383 AS 084 409 383 AT 084 409 383 BA |

| 2.10 2.15 2.20 | 084 409 383 BB 084 409 383 BC 084 409 383 BD |

| 2.25 2.30 2.35 | 084 409 383 BE 084 409 383 BF 084 409 383 BG |

| 2.40 | 084 409 383 BH |

|

|

|

|

|

|

|