Leon Mk1

| Differential: dismantling and assembly |

| Special tools and workshop equipment required |

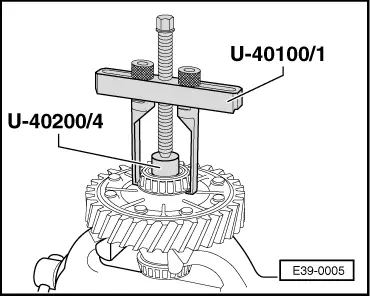

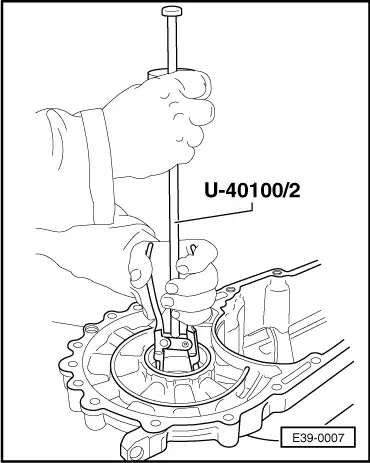

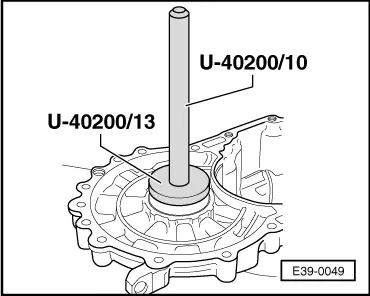

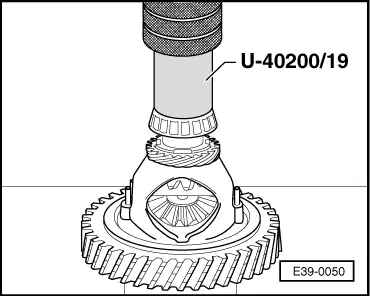

| t | Gearbox extractor set -U-40100- |

| t | Gearbox repair set -U-40200- |

| t | Clip extractor with claws -T20022- |

| t | Electric blower -SAT 1416- |

| t | Digital thermometer -SAT 4002- |

Note!

Note!| t | Heat the inner roller bearing track to 100 °C before fitting |

| t | The two roller bearings should be replaced together |

| t | Adjust the differential whenever the roller bearings are replaced → Chapter |

| 1 - | Gearbox casing |

| 2 - | Shim S1 |

| q | For differential |

| q | Always 1 mm thickness |

| 3 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 4 - | Roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 5 - | Differential crown |

| q | Removing and fitting → Chapter |

| q | Install: refer to section Code letters, group numbers, ratios, filling quantities → Chapter |

| 6 - | Set of thrust washers |

| q | Fit with gear oil |

| 7 - | Planet gear |

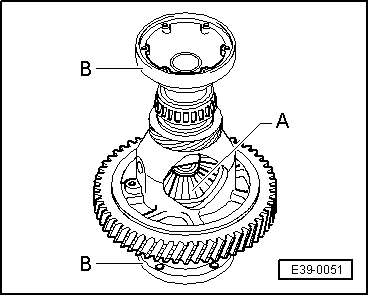

| q | Fit → Fig. |

| 8 - | Component to secure the aticulation flange |

| 9 - | Satellite |

| q | Fit → Fig. |

| 10 - | Satellite shaft |

| q | Remove with a drift |

| 11 - | Speedometer gear |

| q | Remove levering with a screwdriver |

| 12 - | Roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 13 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 14 - | Shim S2 |

| q | For differential |

| q | etermine thickness → Chapter |

| 15 - | Clutch housing |

| 16 - | Bracket |

| q | Secure the satellite shaft in the gearbox with the rivetted crown wheel |

| q | It is secured with the rivets of the diffferential crown wheel → Item |

| 17 - | Elastic pin |

| q | Fit to the centre of the shaft |

| 18 - | Differential casing |

| q | If replaced, refer to Adjustment chart → Chapter |

| 19 - | Rivet |

| q | Only for production |

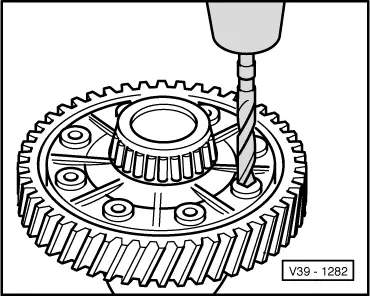

| q | Drill → Fig. |

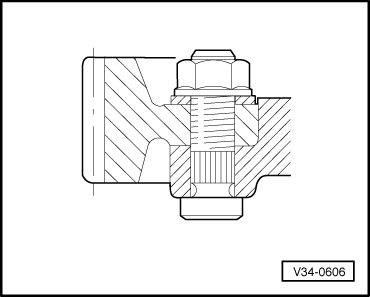

| q | Fit the crown wheel with bolts → Fig. |

| 20 - | Nut |

| q | 70 Nm |

| 21 - | Differential crown wheel, rivetted or bolted |

| q | Rivetted on the production line |

| q | Bolt assembly → Fig. |

Note!

Note!

|

|

Note!

Note!

|

|

Note!

Note!

|

|

|

|

Note!

Note!

|

|

|

|