Leon Mk1

|

|

|

Note!

Note!

|

|

|

|

Note!

Note!

|

|

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

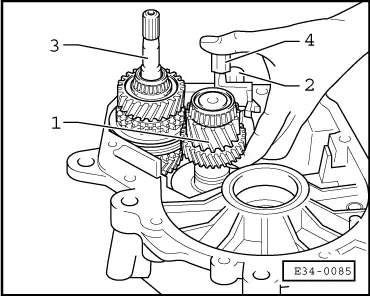

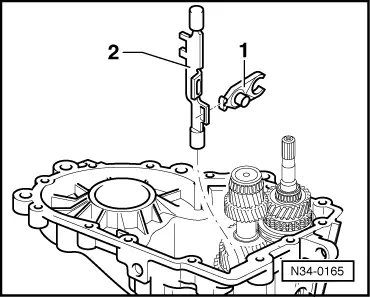

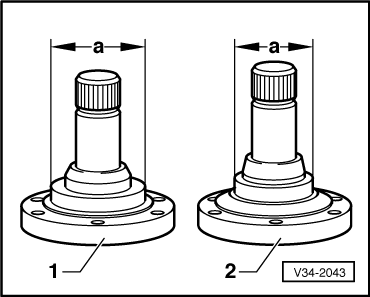

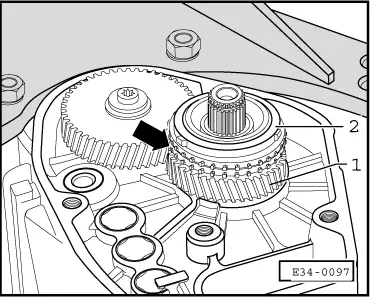

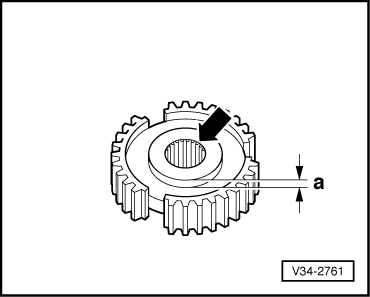

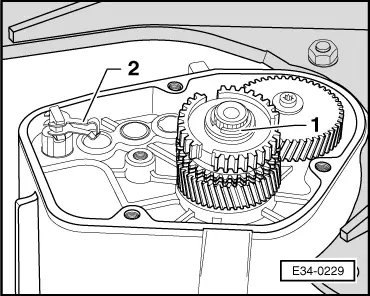

| Item | Flanged shaft | Dimension “a” |

| 1 | left-hand side of gearbox casing | 57 mm |

| 2 | right-hand side of gearbox casing | 48 mm |

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

|

|

|

|

|

|

Note!

Note!

|

|