Leon Mk1

| Layshaft: dismantling and assembling |

| Special tools and workshop equipment required |

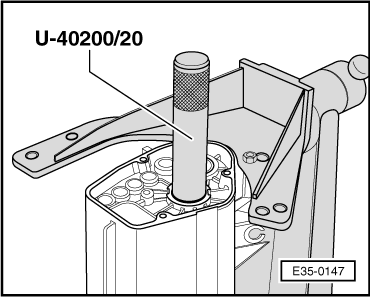

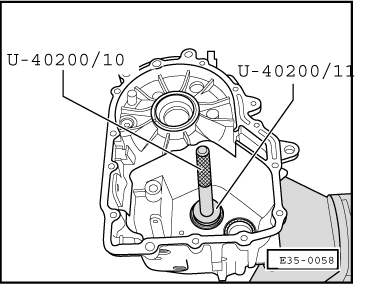

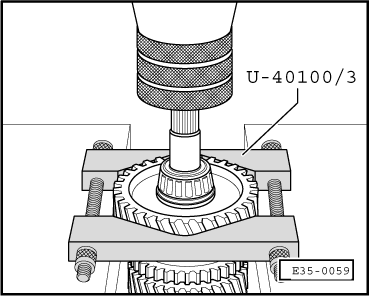

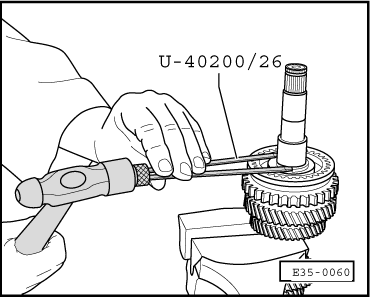

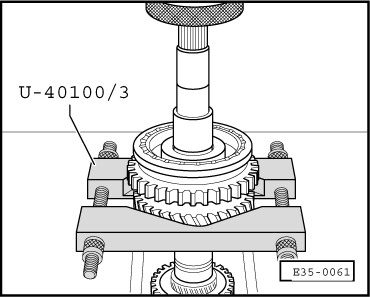

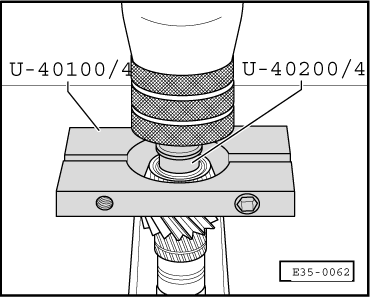

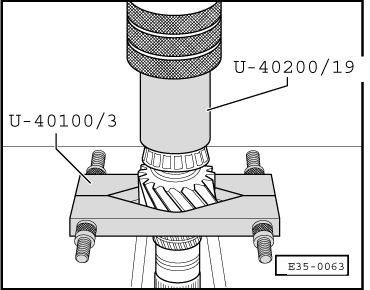

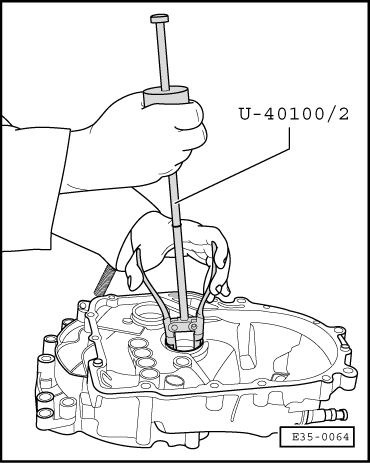

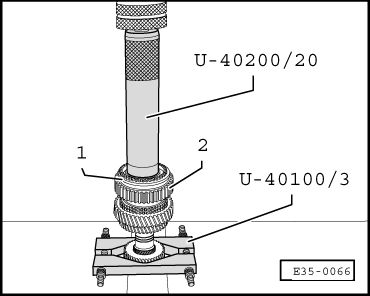

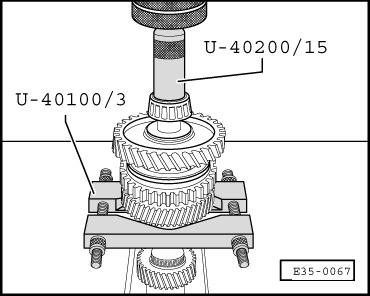

| t | Gearbox extractor set -U-40100- |

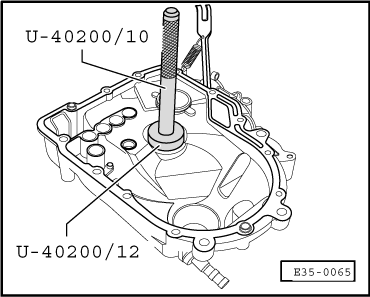

| t | Gearbox repair set -U-40200- |

| t | Circlip opening pliers -A-81124- |

Note!

Note!| t | Whenever new gears or a new layshaft are fitted consult the technical data → Chapter, Code letters, group numbers, ratios, filling quantities |

| t | If the layshaft or the roller bearings are replaced, the layshaft must be adjusted → Chapter |

| t | The layshaft must be adjusted whenever elements have been replaced which could affect the position of the roller bearings. Refer to Adjustment chart → Chapter |

| 1 - | Gearbox casing |

| 2 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

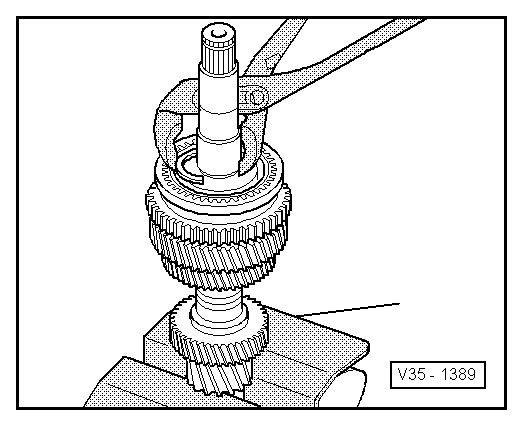

| 3 - | Roller bearing |

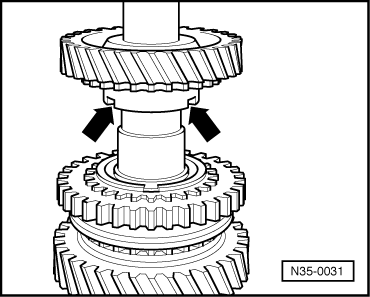

| q | Remove together with 1st gear → Fig. |

| q | Fit → Fig. |

| 4 - | Stop washer |

| 5 - | Sliding 1st gear |

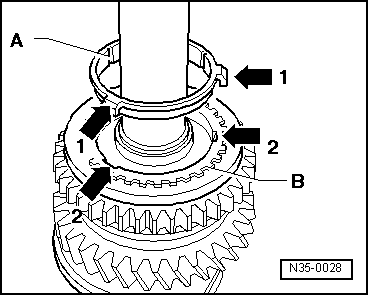

| q | Installation position → Fig. |

| 6 - | Needle roller bearing |

| q | For the sliding 1st gear |

| 7 - | Syncromesh ring |

| q | Inner ring for 1st gear |

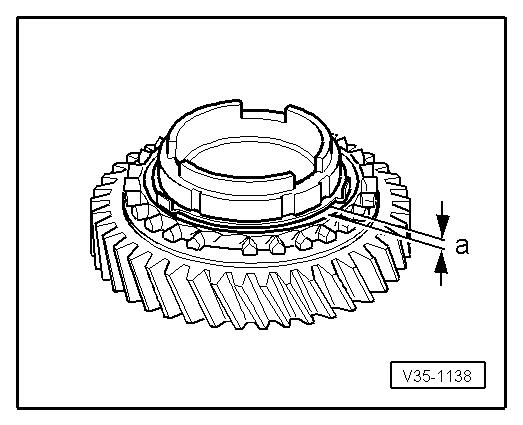

| q | Checking for wear → Fig. |

| q | Theck that the tabs show no signs of wear |

| q | Installation position → Fig. |

| 8 - | Outer ring for 1st gear |

| q | Fit it to the 1st gear syncromesh ring, item → Item |

| q | Installation position → Fig. |

| q | Replace if it shows signs of wear or grooves |

| 9 - | Syncromesh ring 1st gear |

| q | Checking for wear → Fig. |

| q | On fitting, the tabs on the ring must fit into their housings in the syncromesh assembly for 1st and 2nd gear → Item |

| 10 - | Circlip |

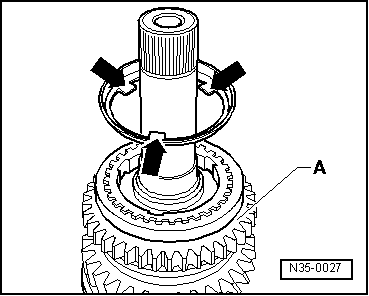

| q | Separation → Fig. |

| q | Location → Fig. |

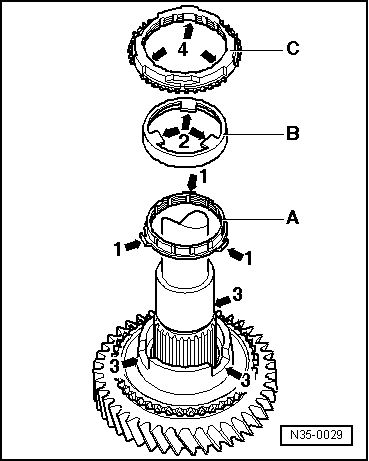

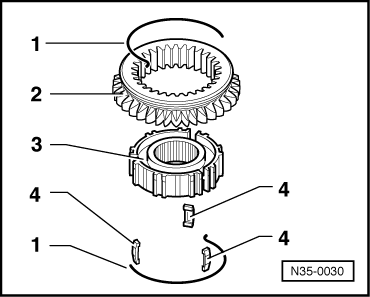

| 11 - | Syncromesh assembly for 1st and 2nd gear |

| q | They are matching pairs |

| q | Remove → Fig. |

| q | Assembly of components → Fig. und → Fig. |

| q | Fit → Fig. |

| 12 - | Spring |

| 13 - | Sliding sleeve |

| 14 - | Syncromesh hub |

| 15 - | Locking keyways |

| q | 3 units |

| 16 - | Spring |

| 17 - | Syncromesh ring 2nd gear |

| q | Checking for wear → Fig. |

| q | Installation position → Fig. |

| 18 - | Outer ring for 2nd gear |

| q | Fit to syncromesh ring → Item |

| q | Installation position → Fig. |

| q | Replace if it shows signs of wear or grooves |

| 19 - | Syncromesh ring |

| q | Inner ring for 2nd gear |

| q | Checking for wear → Fig. |

| q | Check that the tabs show no signs of wear |

| q | Installation position → Fig. |

| 20 - | Sliding 2nd gear |

| 21 - | Safety ring |

| q | Separation → Fig. |

| q | Location → Fig. |

| 22 - | Needle roller bearing |

| q | For sliding 2nd gear |

| 23 - | 3rd gear |

| 24 - | Circlip |

| q | Separation → Fig. |

| q | Location → Fig. |

| 25 - | Circlip |

| q | Separation → Fig. |

| q | Location → Fig. |

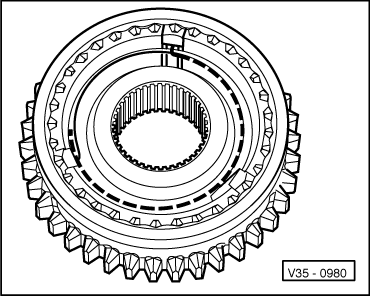

| 26 - | 4th gear |

| q | Assembly position: the identification groove should face the cone |

| 27 - | Layshaft |

| q | Check that the ratio (number of teeth) is correct → Chapter |

| q | Adjusting → Chapter |

| 28 - | Roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 29 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 30 - | Shim |

| q | For the layshaft |

| q | Determine thickness → Chapter |

| 31 - | Clutch housing |

| 32 - | Stop washer |

| q | The step of the shim should be facing the roller bearing |

| 33 - | Needle bearing bush |

| q | Remove → Anchor |

| q | Fit → Anchor |

| 34 - | Needle bearing for gear, 5th gear |

| 35 - | Sliding 5th gear |

| 36 - | Syncromesh ring 5th gear |

| 37 - | Spring |

| q | Fit onto the 5th gear syncromesh ring |

| q | Replace if it shows signs of wear |

| 38 - | Syncromesh hub 5th gear |

| q | Removal, fitting and adjustment → Chapter |

| 39 - | Sliding sleeve 5th gear |

| q | Removal, fitting and adjustment → Chapter |

| 40 - | Circlip |

Note!

Note!

|

|

Note!

Note!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

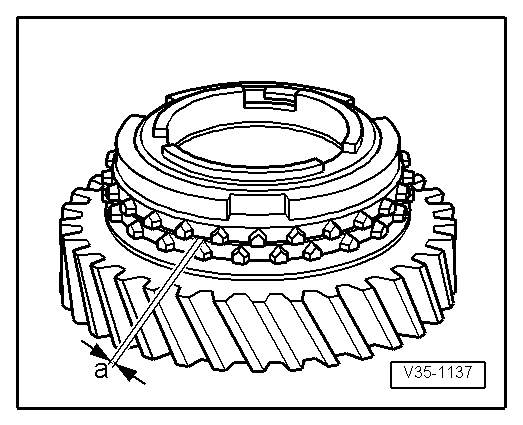

| Ring syncromesh | Measurement “a” on a new syncromesh | Wearlimit |

| 1st and 2nd gears | 0.75...1.25 mm | 0.3 mm |

|

|

| Ring syncromesh | Measurement “a” on a new syncromesh | Wearlimit |

| 1st and 2nd gears | 1.2...1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning

Warning