Leon Mk1

| Differential: dismounting and assembling |

| t | The differential must be adjusted whenever the tapered roller bearings are replaced. |

| t | The tapered roller bearings must always be removed together. Consult the Adjustments Chart → Chapter. |

| t | The tapered roller bearings and their corresponding external tracks are matched. Do not mix them up or exchange them with other bearings. |

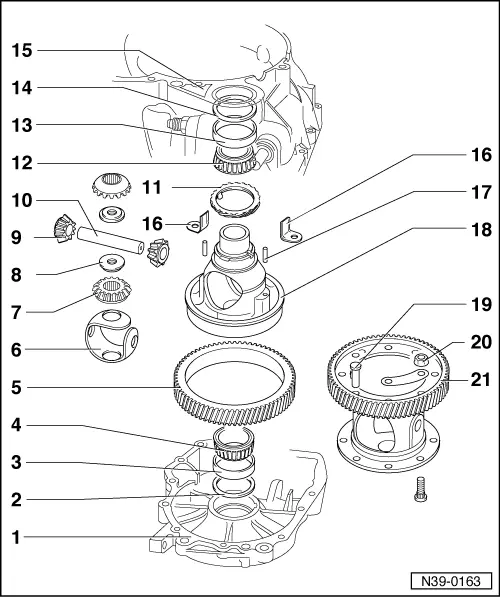

| 1 - | Gearbox casing |

| 2 - | Adjusting washer S1 for the differential |

| q | Always of 1 mm thickness |

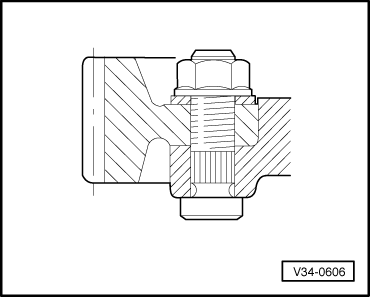

| 3 - | Outer track, tapered roller bearing |

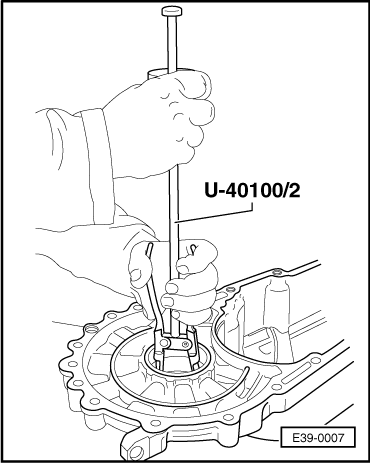

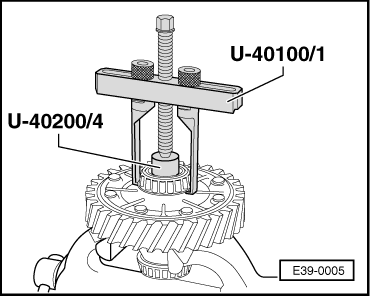

| q | Dismounting → Fig. |

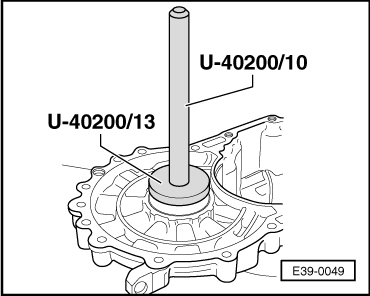

| q | Assembling → Fig. |

| 4 - | Tapered roller bearings |

| q | Dismounting → Fig. |

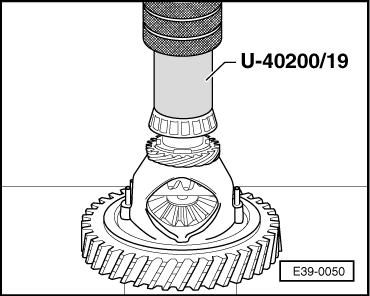

| q | Assembling → Fig. |

| 5 - | Riveted differential crown wheel |

| q | Dismounting and assembly → Chapter |

| q | Assembly: consult the Identification Initials section, group assignment, reduction ratios, filling capacities → Chapter |

| 6 - | Friction washer assembly |

| q | Impregnate with gear oil before assembling |

| 7 - | Sun gear |

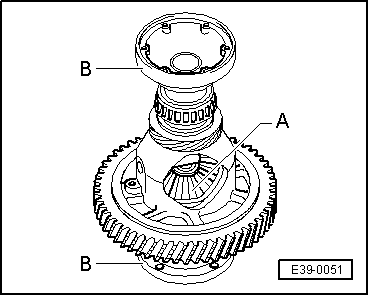

| q | Assembly → Fig. |

| 8 - | Threaded cone for securing the coupled flanges |

| 9 - | Planetary gear |

| q | Assembly → Fig. |

| 10 - | Planetary gear shaft |

| q | Take out by tapping with a punch |

| 11 - | Speedometer mechanism pinion |

| q | Lever out with a flat screwdriver |

| 12 - | Tapered roller bearing |

| q | Dismounting → Fig. |

| q | Assembling → Fig. |

| 13 - | Outer track, tapered roller bearing |

| q | Dismounting → Fig. |

| q | Assembling → Fig. |

| 14 - | Adjusting washer S2 for the differential |

| q | Calculate the thickness → Chapter |

| 15 - | Clutch casing |

| 16 - | Bracket |

| q | Secure the planetary gear shaft in the gearbox with the riveted crown wheel |

| q | This is fixed with the rivets → Item of the crown wheel |

| 17 - | Spring pin |

| q | Insert to the centre of the shaft |

| 18 - | Differential housing |

| q | If replacing, consult the Adjustments chart → Chapter |

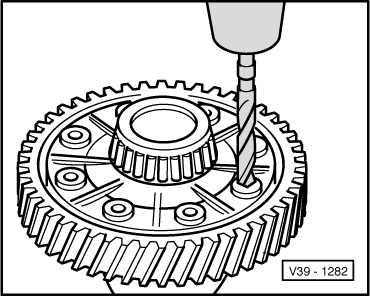

| 19 - | Rivet |

| q | Only for production |

| q | Drilling → Fig. |

| q | Assembly with screws → Fig. |

| 20 - | Nut, 70 Nm |

| 21 - | Riveted crown wheel |

| q | Riveted at the factory |

| q | Assembly with screws → Fig. |

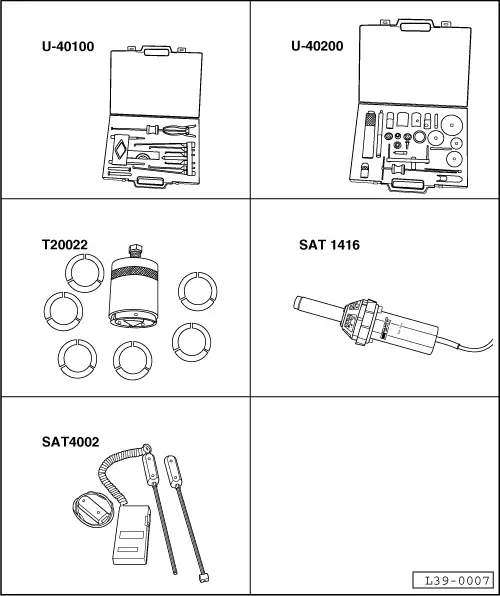

| Special tools and workshop equipment required |

| t | Case of extraction tools for gearboxes -U-40100- |

| t | Case of tools for repairing gearboxes -U-40200- |

| t | Pincer extractor tool with grippers -T20022- |

| t | Electrical blower -SAT 1416- |

| t | Digital thermometer -SAT 4002- |

Note!

Note!

|

|

Note!

Note!

|

|

Note!

Note!

|

|

|

|

Note!

Note!

|

|

|

|