Leon Mk1

| Primary shaft: adjustment |

| Special tools and workshop equipment required |

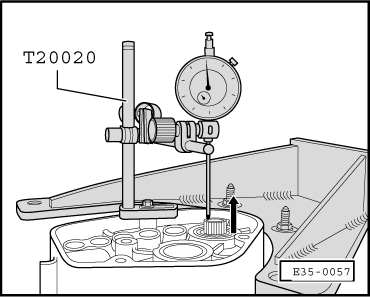

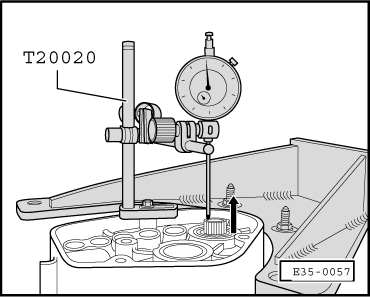

| t | Universal tester stand -T20020- |

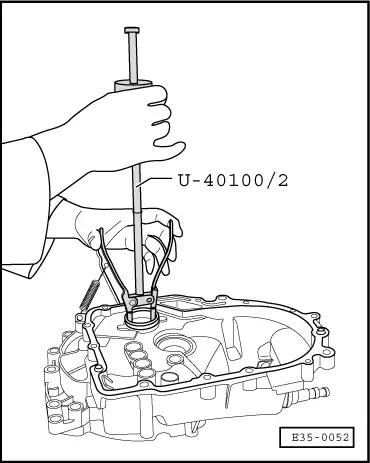

| t | Replacement parts extractors case -U-40100- |

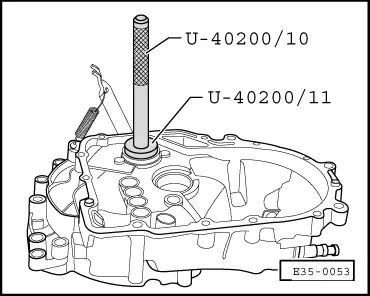

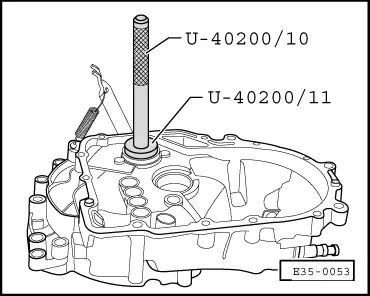

| t | Replacement parts repair case -U-40200- |

|

|

|

Note!

Note!

Note!

Note!

|

|

| Adjusting washer chart |

| Set of bearings | Adjusting washer | |

| Measurement (mm) | Thickness (mm) | Parts Nº |

| …0,66 0,67…0,68 0,69…0,70 | 0,650 0,675 0,700 | 085 311 391 085 311 391 N 085 311 391 A |

| 0,71…0,73 0,74…0,75 0,76…0,78 | 0,725 0,750 0,775 | 085 311 391 P 085 311 391 B 085 311 391 Q |

| 0,79…0,80 0,81…0,82 0,83…0,85 | 0,800 0,825 0,850 | 085 311 391 C 085 311 391 R 085 311 391 D |

| 0,86…0,88 0,89…0,90 0,91…0,93 | 0,875 0,900 0,925 | 085 311 391 S 085 311 391 E 085 311 391 T |

| 0,94…0,95 0,96…0,98 0,99…1,00 | 0,950 0,975 1,000 | 085 311 391 F 085 311 391 AA 085 311 391 G |

| 1,01…1,03 1,04…1,05 1,06…1,08 | 1,025 1,050 1,075 | 085 311 391 AB 085 311 391 H 085 311 391 AC |

| 1,09…1,10 1,11…1,13 1,14…1,16 | 1,100 1,125 1,150 | 085 311 391 J 085 311 391 AD 085 311 391 K |

| 1,17…1,18 1,19…1,20 1,21…1,23 | 1,175 1,200 1,225 | 085 311 391 AE 085 311 391 L 085 311 391 AF |

| 1,24…1,26 1,27…1,28 1,29…1,30 | 1,250 1,275 1,300 | 085 311 391 M 085 311 391 AG 085 311 391 AH |

| 1,31…1,33 1,34…1,36 1,37…1,38 | 1,325 1,350 1,375 | 085 311 391 AJ 085 311 391 AK 085 311 391 AL |

| 1,39…1,40 1,41…1,43 1,44…1.46 | 1,400 0,700 + 0,725 0,700 + 0,750 | 085 311 391 AM 085 311 391 A + P 085 311 391 A + B |

| 1,47…1,48 1,49…1,50 1,51…1,53 | 0,700 + 0,775 0,700 + 0,800 0,700 + 0,825 | 085 311 391 A + Q 085 311 391 A + C 085 311 391 A + R |

| 1,54... 1,56 1,57…1,58 1,59…1,61 | 0,700 + 0,850 0,700 + 0,875 0,700 + 0,900 | 085 311 391 A + D 085 311 391 A + S 085 311 391 A + E |

| 1,62…1,63 1,64…1,66 1,67…1,68 1,69…1,70 | 0,700 + 0,925 0,700 + 0,950 0,700 + 0,975 0,700 + 1,000 | 085 311 391 A + T 085 311 391 A + F 085 311 391 A + AA 085 311 391 A + G |

|

|

|

|

|

Note!

Note!

|

|