Leon Mk1

| Secondary shaft: adjustment |

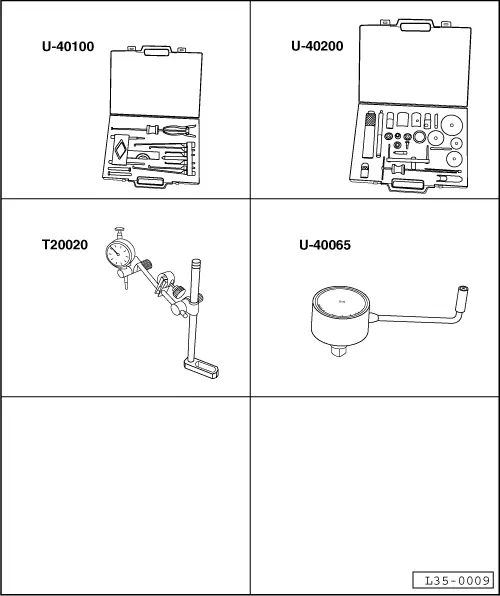

| Special tools and workshop equipment required |

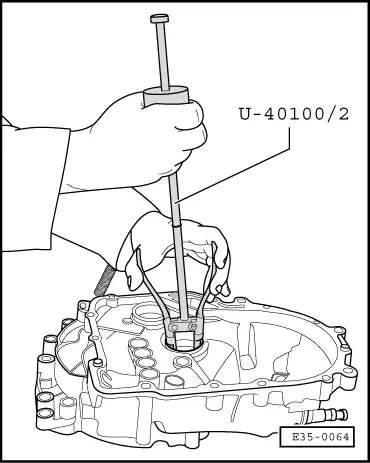

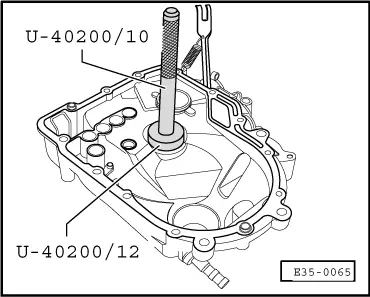

| t | Case for extractors for gearboxes -U-40100- |

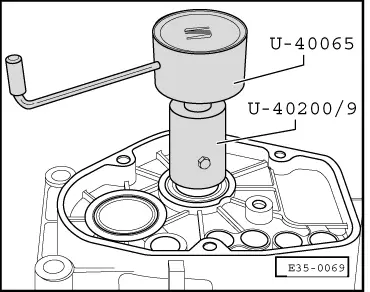

| t | Replacement parts repair case -U-40200- |

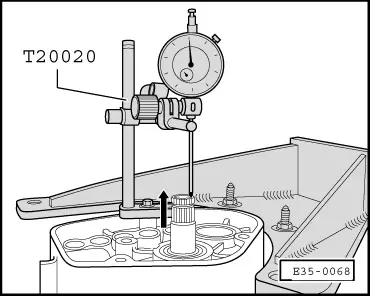

| t | Multi-purpose stand for the comparator -T20020- |

| t | Turning torque tester -U-40065- |

|

|

|

Note!

Note!

Note!

Note!

|

|

| Reading obtained with the comparator | 0,30 mm |

| Thickness of the washer already mounted | 0,75 mm |

| Set value | 0,20 mm |

| Thickness of the adjustment washer needed | 1,25 mm |

|

| Thickness (mm) | Parts Nº |

| 0,70 | 020 311 391 Q |

| 0,75 0,80 0,85 | 020 311 391 020 311 391 A 020 311 391 B |

| 0,90 0,95 1,00 | 020 311 391 C 020 311 391 D 020 311 391 E |

| 1,05 1,10 1,15 | 020 311 391 F 020 311 391 G 020 311 391 H |

| 1,20 1,25 1,30 | 020 311 391 J 020 311 391 K 020 311 391 L |

| 1,35 1,40 | 020 311 391 M 020 311 391 N |

|

|

|

|

|

|

|