Leon Mk1

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

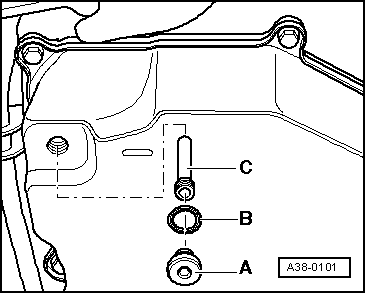

| Component | Nm |

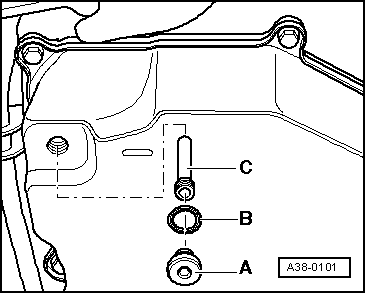

| ATF drain bolt to the oil pan, M18 | 39 |

| Oil tube on the oil sump | 1 |

| ATF level testing bolt to the oil pan, M10 | 27 |

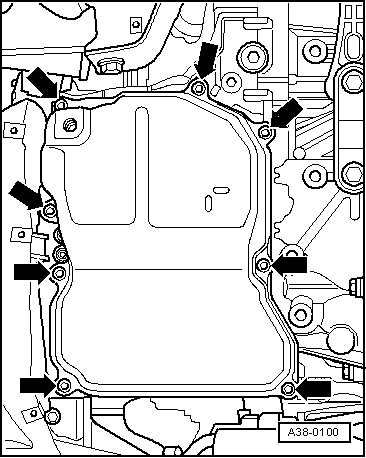

| Oil sump to the gearbox housing, 8 M6 bolts | 7 → Remark |

|

WARNING

WARNING