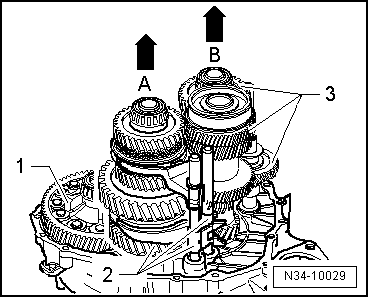

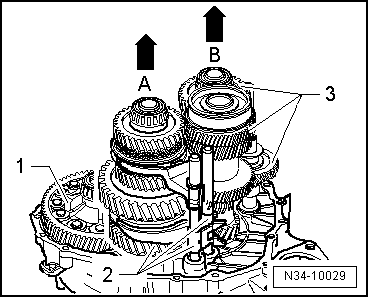

| To remove the shafts from the clutch housing, a second mechanic is required. |

| –

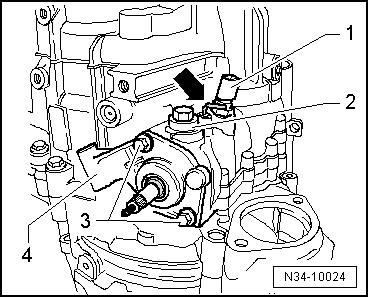

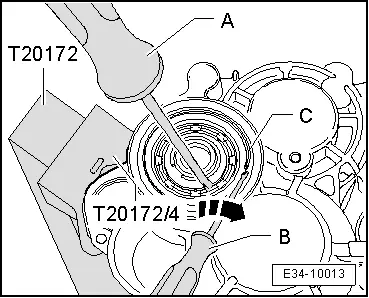

| Lift the differential gear -1- with the left hand. |

| –

| Use the right hand to lift the secondary shaft for the 1st to 4th gears along with the control rod -2-, -arrow A-. |

| –

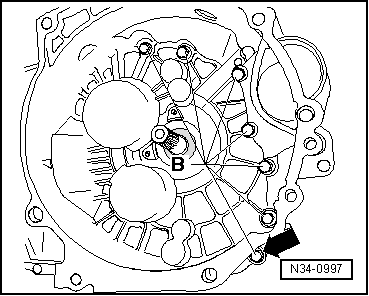

| At the same time, the second mechanic must remove the primary, inverter and secondary shaft of the 5th/6th gears -3-, along with the control rods, out of the clutch housing -arrow B-. |

Note | In case of doubt, the differential may rest on the clutch housing after lifting the shafts. |

| –

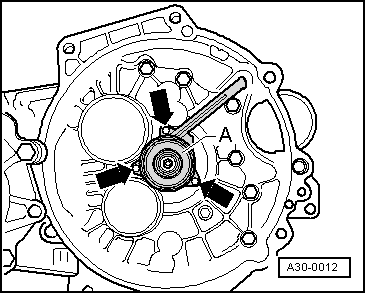

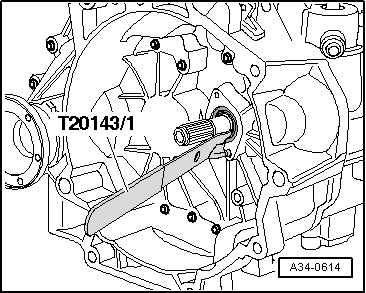

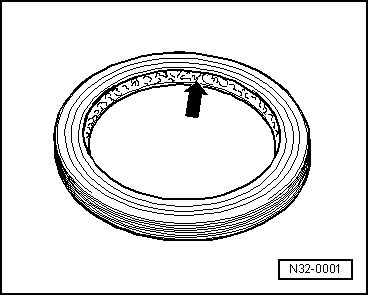

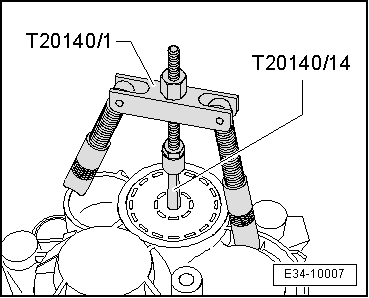

| Release the input shaft oil seal → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note