Leon Mk1

|

| Special tools and workshop equipment required |

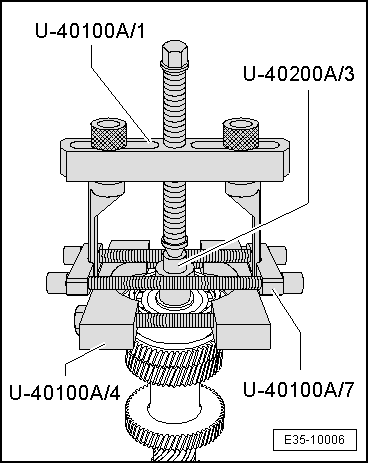

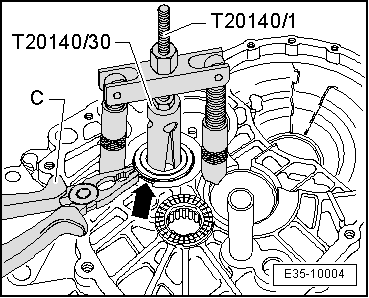

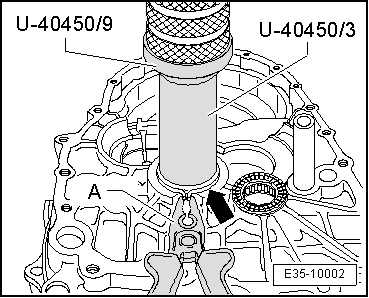

| t | Extractor kit -T20140-, see equivalent → Anchor |

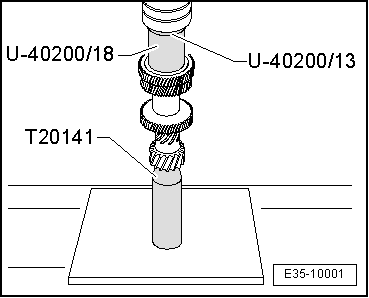

| t | Counterhold -T20141-, see equivalent → Anchor |

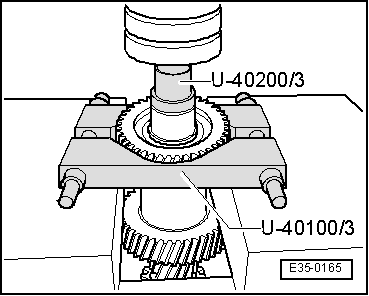

| t | Extractor kit -U 40100B-, see equivalent → Anchor |

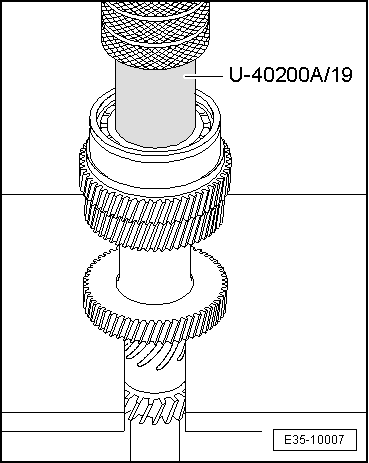

| t | Kit (case) -U 40200A-, see equivalent → Anchor |

| t | Kit (case) -U 40450A-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

| Measured value (mm) | Thickness of the securing ring (mm) | Axial play (mm) |

| 0,01 … 0,05 | 1,86 | 0,01 … 0,05 |

| 0,05 … 0,07 | 1,89 | 0,01 … 0,05 |

| 0,07 … 0,10 | 1,92 | 0,01 … 0,05 |

| 0,10 … 0,13 | 1,95 | 0,01 … 0,05 |

| 0,13 … 0,16 | 1,98 | 0,01 … 0,05 |

|

|

|

|